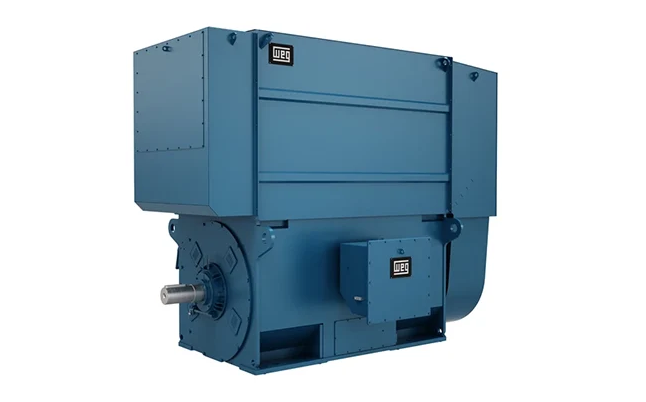

The Master Line WEG Motor Three Phase Induction Motor: A Basic Guide

For the most demanding operations demanding steady and high power, VIBRANT Master Line Three-phase Induction WEG Motor is the best solution to get. Primarily focused on power sectors which include mining, cement, oil, and gas amongst many others this particular motor is impressive in its performance levels. In this article, we will be examining why VIBRANT WEG motor is right for you, how to select the right motor, and how beneficial it is to make the choice of this superior product.

Why the VIBRANT Master Line Three-Phase Induction Motor Is Ideal?

The VIBRANT Master Line Three-Phase Induction WEG Motor is designed for high performance, and high energy efficiency and resists wear and tear due to demands of various industries. The following are the features that make it a suitable tool for your severe operations:

Robust Construction for Heavy-Duty Use

This kind of WEG motor is made of robust and sturdy materials in order to enable it to be used in extreme environmental conditions as well as serving the user for a very long time. Thus any industry that involves mining, steel production, or cement manufacture this type of motor is the most appropriate since it is reliable, efficient, and durable.

Energy Efficient with Low Operating Costs

Due to having efficiency rates for the IE2 to IE5, this Master Line WEG Motor will assist you in saving energy in order to cut costs. The motor can work at different voltages which range from 13.8 kV and different frequencies of (50 or 60 Hz) thus it can be mobile without consuming a lot of energy.

Low Noise and Vibration

In the aspect of operational noise, the motor is quiet and has low vibrations, which enhances the work environment. Apart from lacking the problems associated with noise pollution to the people in the surroundings, low noise levels are crucial since they result in extended durability of the mechanical parts thus increasing the motor durability.

Customizable Cooling Systems

In this aspect, the cooling options include air-air, air-water, and self-venting depending on the required system need. The systems used for cooling are also quite flexible to suit the performance in extreme climates.

Why the Master Line Motor is Significant for Your Industry?

Versatility across Various Industries

That is why the VIBRANT Master Line Motor is not only popular among mining or oil & gas organizations but also in wastewater treatment, the cement industry, the steel industry, the marine industry, and almost all others. Its reliability in all the hostile working conditions makes it a valuable commodity in various industries.

Durability and Reliability for Long-Term Use

The VPI process used for the motor’s coils yields this motor with impeccable insulation which is free from any deleterious gases and is perfect for high temperatures. Regardless of the type of climate it is exposed to, whether it is extremely humid or dusty, the VIBRANT WEG motor can assemble and function to the optimum.

Minimal Maintenance Requirements

In this respect, the Master Line WEG Motor has two main advantages – reduced maintenance requirements and high efficiency. This is because it has an extended service cycle for each ball bearing which also means that it is easy to manage the lubrication resulting in less frequent maintenance hence less time is spent on it.

Optimized Insulation System

However, there is an insulation system reserved for high-voltage motors known as the MICATHERM insulation system which is highly recommendable since it has high mechanical, thermal as well as environmental endurance. This makes the Master Line motor highly durable and is ideal for use in industries that can barely afford to be faced with motor failures.

How to Choose the Right Master Line WEG Motor for Your Application?

Motor selection is important so as to get the best one to meet all the power and efficiency needs of the respective application. The following factors should be observed when selecting the VIBRANT WEG motor:

Understand Your Power Requirements

Master Line Three-Phase Induction Motor is available in a number of power and voltage classes. When choosing the motor, it is critical to take into consideration the voltage which is; up to 13.8 kV, and the frequency which ranges from 50 Hz- to 60 Hz. This will ensure that the motor is fitting for your infrastructure to avoid situations that may lead to a change of motor company.

Select the Appropriate Cooling System

According to the environmental conditions where the construction is to be carried out, one can opt for either air-to-air, air-to-water, or self-circulating coolants. However, if the specific industry in which the motor is installed demands continued motor operation under high temperatures, using the air-water cooling type would be best.

Consider Environmental Protection

Make sure that the Master Line motor is protected enough in case your motor will work in a damp, dusty, or corrosive area. The motor’s protection level or IP rating must correspond to these factors so that the electric motor does not get easily damaged or encounter some mechanical issues.

Choose the Right Insulation Class

The VIBRANT WEG motor has F-class and H-class insulations depending on the extent of the temperature prevailing in the environment. Machine insulation classes greater than class 157-2 should be used in industries where conditions are stiff or temperatures are high.

Why Choose the VIBRANT Master Line Motor?

High Quality and Reliability

WEG motor is one of the Master Lines of VIBRANT, which is capable of performing optimally even in the harshest environments. It is long-lasting, economical on power, and easy to maintain is the perfect solution for any company that seeks to increase productivity and reduce incidences of injuries.

Energy Savings

WEG motor also ensures that industries can contain their power cost by effectively reducing energy usage by the motor. This is a clear indicator that you can always access IE2 to IE5 efficiency classes, depending on your energy efficiency needs.

Long-Term Value

As a result of its well-built structure, maximum efficiency, and little requirement for maintenance, Master Line WEG Motor is an excellent value for money. It saves the industries from frequent repairs, minimizes the times the machines are out of order and thereby increases the productivity of the industries.

Versatile Applications

The VIBRANT WEG motor can be applied to the mining, cement, oil and gas, marine, and electric power industries. This is why it is the preferred choice for industrial uses if the need arises for a robust and highly efficient motor engine.

Conclusion

The Master Line Three-Phase Induction WEG Motor is an essential piece of equipment for industries that require reliable, energy-efficient, and long-lasting motors. With its high-power output, low-maintenance design, and versatile cooling options, it ensures optimal performance in the most demanding environments. If you are looking for a motor that can handle the toughest industrial challenges, VIBRANT Master Line WEG Motor is the ideal choice for you.