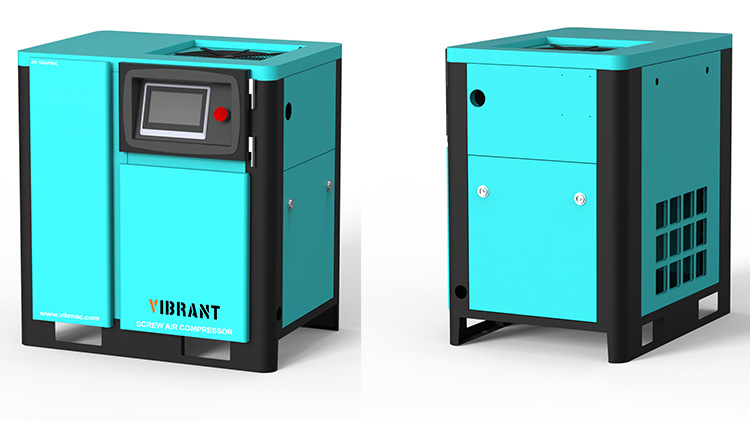

PM VSD Screw Air Compressor

Stable and reliable: A good beginning, fast control, overshoot, and steady-state performance.

High efficiency and energy saving: The VSD screw air compressor modulates speed in operation as a means of efficiency.

Start without impact: The soft starter reduces the startup current to 1.2 times the rated current thus they are absorbent.

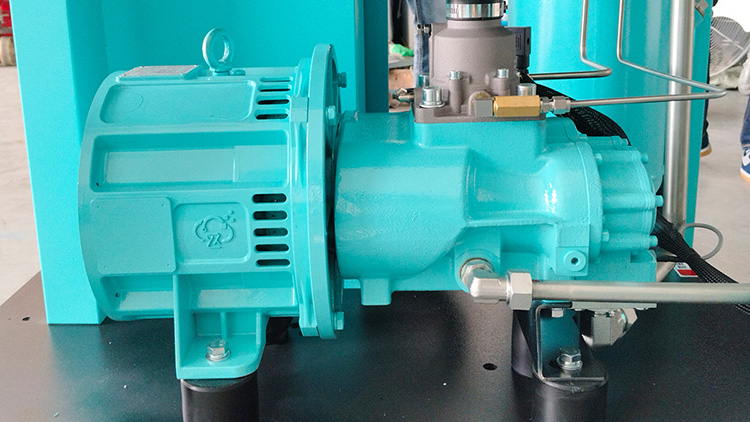

No oil leakage: It uses the high-performance air end developed in Germany, it does not carry out oil leakage.

Lower noise and vibration: These positive effects decrease noise as well as wear, and maintenance rates thus serving as high-efficiency insulation and sealing.

Lower maintenance costs: Low power requirements and the use of high-quality components increase the useful lifespan and cut down on the amount of maintenance required.

Intelligent operation: The controller keeps track of up to 20 different parameters, it anticipates maintenance and even decreases times.

Micro-oil lubrication: Micro-oil injection technology gives better quality of the compressed air than the standard quality of the compressed air.

The efficiency of permanent magnet synchronous motors is 3%-5% higher than ordinary motors, and the efficiency is constant, so that even if the speed is reduced, the high efficiency is still maintained.

PM VSD Screw Air Compressor is quick to maintain, with a small number of consumable parts, low maintenance cost, and simple and convenient replacement.

The PM VSD Screw Air Compressor utilizes PTC temperature sensors, which are managed through a controller that activates the appropriate protection mechanisms when the temperature is abnormal. These protection mechanisms prevent serious motor failure due to abnormal temperatures, ensuring stable motor operation and the normal operation of the entire equipment system.