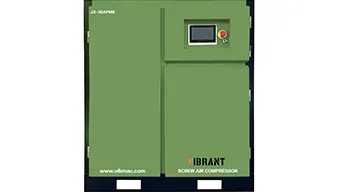

Screw Air Compressor

High Efficiency: It features a rotary screw design where more air is delivered at a lower energy cost as opposed to other competitive products.

Continuous Operation: Provides constant flow to the user and is ideal for pressure-demand applications.

Low Noise Level: Runs very quietly, therefore, can be of great use in places that require low levels of noise.

Minimal Maintenance: Built for efficient and simple cleaning, with minimal downtime on upkeep and service thus, cutting costs greatly.

-

Pressure(MPa): 0.2/0.3/0.4/0.5

-

FAD (m³/min): 60/50/44/34

-

Power(KW/HP): 160/220

-

Weigt(kg): 6500/6200/4300/4000

-

Pipe Diameter: DN200/DN100/DN100

-

Dimension(mm): 3600*2200*2200/3000*1900*1950

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.2/0.3/0.4/0.5

-

FAD (m³/min): 52/42/33/30.5

-

Power(KW/HP): 132/180

-

Weigt(kg): 5800/4300/4100/3700

-

Pipe Diameter: DN200/DN125/DN100/DN80

-

Dimension(mm): 3600*2200*2200/3000*1900*1950

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.2/0.3/0.4/0.5

-

FAD (m³/min): 43/34/29.6/24/

-

Power(KW/HP): 110/150

-

Weigt(kg): 5300/4000/3500/3200

-

Pipe Diameter: DN200/DN125/DN100/DN80

-

Dimension(mm): 3600*2200*2200/3000*1900*1950

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.2/0.3/0.4/0.5

-

FAD (m³/min): 34/28/24/20

-

Power(KW/HP): 90/125

-

Weigt(kg): 3100/3100/3000/2950

-

Pipe Diameter: DN125/DN100/DN80

-

Dimension(mm): 3000*1900*1950/2500*1650*1900

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.2/0.3/0.4/0.5

-

FAD (m³/min): 27/24/20.5/17

-

Power(KW/HP): 75/100

-

Weigt(kg): 3000/2900

-

Pipe Diameter: DN125/DN100/G2

-

Dimension(mm): 2500*1650*1900/2100*1300*1650

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.2/0.3/0.4/0.5

-

FAD (m³/min): 17/13.5/11.8/10

-

Power(KW/HP): 45/60

-

Weigt(kg): 2500/1500/950

-

Pipe Diameter: DN100/DN80/G2

-

Dimension(mm): 2500*1650*1900/2100*1300*1650/1700*1200*1550

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.2/0.3/0.4/0.5

-

FAD (m³/min): 20.5/17/14.2/13.3

-

Power(KW/HP): 55/75

-

Weigt(kg): 2900/1600/1550

-

Pipe Diameter: DN125/DN100/DN80/G2

-

Dimension(mm): 2500*1650*1900/2100*1300*1650

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.3/0.4/0.5

-

FAD (m³/min): 11.8/10/8

-

Power(KW/HP): 37/50

-

Weigt(kg): 1300

-

Pipe Diameter: DN80/G2

-

Dimension(mm): 2100*1600*1650/1700*1200*1550

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

-

Dimension(mm): 1750*1240*1600

-

Noise dB(A): ≤70±2

-

Weigt(kg): 1096

-

Pipe Diameter: G2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 43~31.2

-

Power(KW/HP): 250/ 340

-

Dimension(mm): 3620*2200*2250

-

Noise dB(A): ≤86±2

-

Weigt(kg): 5960

-

Pipe Diameter: DN100

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 38~28.6

-

Power(KW/HP): 220/300

-

Dimension(mm): 3620*2200*2250

-

Noise dB(A): ≤86±2

-

Weigt(kg): 5600

-

Pipe Diameter: DN100

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 33~25.4

-

Power(KW/HP): 200/ 270

-

Dimension(mm): 3620*2200*2250

-

Noise dB(A): ≤86±2

-

Weigt(kg): 5350

-

Pipe Diameter: DN100

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 30~23.3

-

Power(KW/HP): 185/ 250

-

Dimension(mm): 3050*1900*2000

-

Noise dB(A): ≤84±2

-

Weigt(kg): 4320

-

Pipe Diameter: DN80

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 27.2~21.2

-

Power(KW/HP): 160/ 200

-

Dimension(mm): 3050*1900*2000

-

Noise dB(A): ≤84±2

-

Weigt(kg): 4150

-

Pipe Diameter: DN80

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 23~16.2

-

Power(KW/HP): 132/ 175

-

Dimension(mm): 2550*1680*1900

-

Noise dB(A): ≤82±2

-

Weigt(kg): 2900

-

Pipe Diameter: DN80

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 19.8~14.5

-

Power(KW/HP): 110/150

-

Dimension(mm): 2550*1680*1900

-

Noise dB(A): ≤82±2

-

Weigt(kg): 2680

-

Pipe Diameter: DN80

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 44~35.5

-

Power(KW/HP): 250/350

-

Dimension(mm): 3760*2260*2200

-

Weigt(kg): 6300

-

Pipe Diameter: DN125

-

Startup Mode: Variable Frequency Start

-

Power Supply: Tree-phase 380V/50Hz , Can be customized

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 38~28.8

-

Power(KW/HP): 220/300

-

Dimension(mm): 3550*2300*2300

-

Weigt(kg): 5800

-

Pipe Diameter: DN125

-

Startup Mode: Variable Frequency Start

-

Power Supply: Tree-phase 380V/50Hz , Can be customized

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 32.5~25.5

-

Power(KW/HP): 200/270

-

Dimension(mm): 3550*2300*2300

-

Weigt(kg): 5300

-

Pipe Diameter: DN125

-

Startup Mode: Variable Frequency Start

-

Power Supply: Tree-phase 380V/50Hz , Can be customized

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 30~23

-

Power(KW/HP): 185/250

-

Dimension(mm): 3250*2100*2200

-

Weigt(kg): 4200

-

Pipe Diameter: DN100

-

Startup Mode: Variable Frequency Start

-

Power Supply: Tree-phase 380V/50Hz , Can be customized

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 28.5~21.5

-

Power(KW/HP): 160/220

-

Dimension(mm): 3250*2100*2200

-

Weigt(kg): 4000

-

Pipe Diameter: DN100

-

Startup Mode: Variable Frequency Start

-

Power Supply: Tree-phase 380V/50Hz , Can be customized

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 23~16

-

Power(KW/HP): 132/180

-

Dimension(mm): 2250*1510*1850

-

Weigt(kg): 2500

-

Pipe Diameter: DN65

-

Startup Mode: Variable Frequency Start

-

Power Supply: Tree-phase 380V/50Hz , Can be customized

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 19.9~14.5

-

Power(KW/HP): 110/150

-

Dimension(mm): 2250*1510*1850

-

Weigt(kg): 2300

-

Pipe Diameter: DN65

-

Startup Mode: Variable Frequency Start

-

Power Supply: Tree-phase 380V/50Hz , Can be customized

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 15.2~11.4

-

Power(KW/HP): 75/100

-

Dimension(mm): 1500*1230*1550

-

Weigt(kg): 950

-

Pipe Diameter: G2

-

Startup Mode: Variable Frequency Start

-

Power Supply: Tree-phase 380V/50Hz , Can be customized

VIEW MORE

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 106/101/96/85/79

-

Power(KW/HP): 450/600

-

Weigt(kg): 10000

-

Pipe Diameter: DN150

-

Dimension(mm): 4200*2300*2300

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 92.5/89/84.5/77/64

-

Power(KW/HP): 400/540

-

Weigt(kg): 10000

-

Pipe Diameter: DN125

-

Dimension(mm): 4700*2250*2420

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 85/81/78/64/56

-

Power(KW/HP): 355/480

-

Weigt(kg): 9500

-

Pipe Diameter: DN125

-

Dimension(mm): 4700*2250*2420

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 81/74/67/59/52

-

Power(KW/HP): 315/420

-

Weigt(kg): 8500

-

Pipe Diameter: DN125

-

Dimension(mm): 4300*2300*2430

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 63.5/62/59/52/43

-

Power(KW/HP): 280/380

-

Weigt(kg): 7500

-

Pipe Diameter: DN125

-

Dimension(mm): 3760*2260*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 58/55.5/53/45.8/40.5

-

Power(KW/HP): 250/350

-

Weigt(kg): 7000

-

Pipe Diameter: DN125

-

Dimension(mm): 3760*2260*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 53/50/46/41/35

-

Power(KW/HP): 220/300

-

Weigt(kg): 6300

-

Pipe Diameter: DN125

-

Dimension(mm): 3550*2300*2300

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 48.8/46/42/38/31.5

-

Power(KW/HP): 200/270

-

Weigt(kg): 5800

-

Pipe Diameter: DN125

-

Dimension(mm): 3550*2300*2300

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.4/0.5

-

FAD (m³/min): 65/61

-

Power(KW/HP): 250/350

-

Weigt(kg): 8500

-

Pipe Diameter: DN125

-

Dimension(mm): 4300*2300*2430

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.4/0.5

-

FAD (m³/min): 62/55

-

Power(KW/HP): 220/300

-

Weigt(kg): 8000

-

Pipe Diameter: DN125

-

Dimension(mm): 4300*2300*2430

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.4/0.5

-

FAD (m³/min): 57/51.5

-

Power(KW/HP): 200/270

-

Weigt(kg): 6000

-

Pipe Diameter: DN125

-

Dimension(mm): 3550*2300*2300

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.4/0.5

-

FAD (m³/min): 52/45

-

Power(KW/HP): 185/250

-

Weigt(kg): 5800

-

Pipe Diameter: DN125

-

Dimension(mm): 3550*2300*2300

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.4/0.5

-

FAD (m³/min): 47/42

-

Power(KW/HP): 160/220

-

Weigt(kg): 5500/4400

-

Pipe Diameter: DN125/DN100

-

Dimension(mm): 3550*2300*2300/3250*2100*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.4/0.5

-

FAD (m³/min): 38/35

-

Power(KW/HP): 132/180

-

Weigt(kg): 4000

-

Pipe Diameter: DN100

-

Dimension(mm): 3250*2100*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.4/0.5

-

FAD (m³/min): 28/27

-

Power(KW/HP): 110/150

-

Weigt(kg): 2900

-

Pipe Diameter: DN80

-

Dimension(mm): 2600*1900*1890

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.4/0.5

-

FAD (m³/min): 20.5/19.5

-

Power(KW/HP): 75/100

-

Weigt(kg): 2800/2400

-

Pipe Diameter: DN80/DN65

-

Dimension(mm): 2600*1900*1890/2450*1700*1765

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

Permanent magnet frequency conversion, the first choice for energy saving. Realize constant pressure gas supply, provide users with stable gas source; smooth startup, reduce the impact of motor startup on the power grid, prolong the mechanical life of the motor and the unit; frequency converter can be provided randomly or upgraded at a later date.

Humanized design, so that you can easily operate and maintain the compressor, better for the production services. Integrated into the skid, compact design, easy to install; a control panel controls all the parts, and the graphical operation interface is more simple and easy to use; the number of consumable parts is small, easy to replace, and no lifting equipment is needed for maintenance; the control system has a self-diagnostic fault function, which enables you to quickly eliminate the faults and safeguard the production; a full range of safety protection and eye-catching operation and warning reminders, which makes the unit run more safely.

High reliability design ensures continuous and reliable operation of the air compressor, which is the best guarantee for stable production. The rotors adopt reasonable compression ratio, which reduces the wear and tear between the rotors; the air and water pipelines are made of food-grade stainless steel, which ensures the quality of the gas and prolongs the life of the unit.The air cushion valve, the inlet and exhaust of all levels of the booster adopts imported or domestic famous brand parts, which has a long service life.

-

What advantages do screw air compressors have over traditional compressors?

-

They consist of dispersed screws and provide continuous airflow, higher efficiency, and lower cost of energy than piston compressors required for industrial applications.

-

How often do screw air compressors require maintenance?

-

It is generally less demanding when it comes to maintenance because of its built-in simplicity in its working mechanisms and components but must be regulated keenly.

-

Can screw air compressors operate in high-demand environments?

-

Indeed they are mainly used for demanding operations and offer a constant flow of air regardless of the surrounding conditions.

-

What industries benefit most from screw air compressors?

-

A screw air compressor is an important tool for industries like manufacturing, construction, automotive, food processing industries, etc. due to its versatility in its usage.