Tank Mounted Screw Air Compressor for Manufacturing: Why It’s the Best Choice

2024-12-25

Why Tank Mounted Screw Air Compressors Are Perfect for Manufacturing?

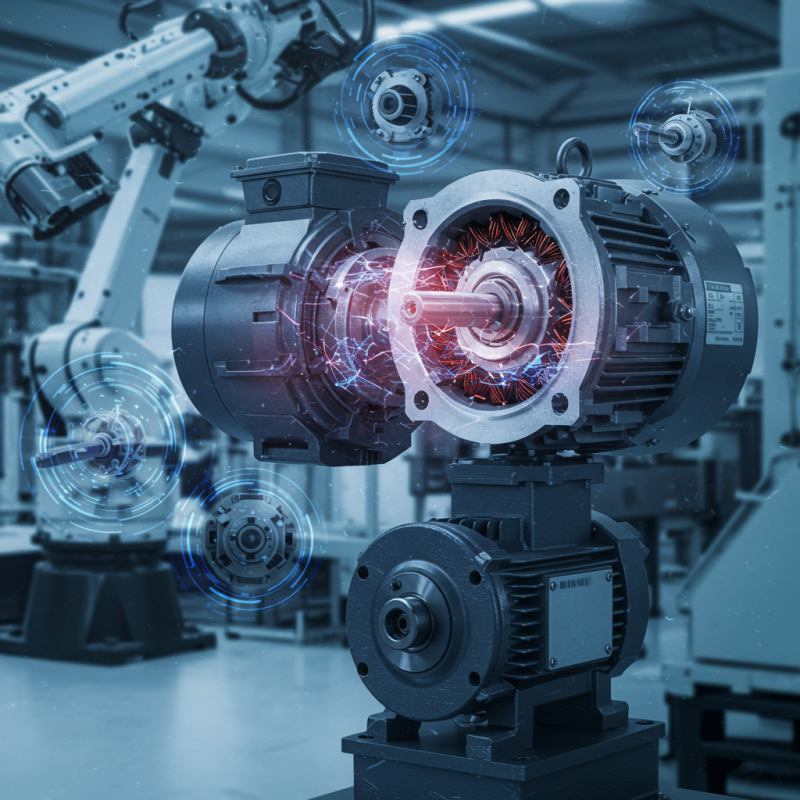

Such air compressors include tank mounted screw air compressors – and these are some of the most revolutionary elements in the industrial environment. These essentially are small but robust systems made of Screw Air Compressor for Manufacturing and the air receiver that offers consistent, efficient, and hence, high caliber compressed air. Employees in manufacturing industries, automotive maintenance, construction, and many others always depend on these compressors to ensure continuity of service delivery. Generators are widely used in manufacturing plants and industries, and the reasons for using these compressors are listed in this article, why you should choose them, and the steps to follow to secure the best compressor in the market.

Tank Mounted Screw Air Compressor – what is this?

A Tank Mounted Screw Air Compressor, therefore, refers to an assembling of a screw compressor and an air storage tank in a single set-up. Air receivers are used to store compressed air and help smooth out pressure changes that may occur, allowing the system to continue to operate at the most efficient level possible.

Key Features of Tank Mounted Screw Air Compressors:

• Energy Efficiency: Works at a constant power level, thus minimizing power wastage.

• Compact Design: Compact design and installation are possible even in the cramped area.

• High Work Efficiency: Provides reasonably constant air supply with limited interruptions.

• Low Noise Levels: Suitable for working environments that require low levels of noise interference.

• Durable Build: Manufactured for the most severe industrial usage conditions.

Why Tank Mounted Screw Air Compressors Are Perfect for Manufacturing?

Stable Power Output

Compressed air is also needed in manufacturing procedures to make machines run properly and it has to be constant in supply. Tank mounted screw air compressor provides constant power because of compressed air storage in the tank so there are no problems with pressure dropping or too high pressure, so the supply is ongoing. This stability is important for ensuring that production processes do not lose the expensive precision instruments.

Energy-Saving Design

This energy is the main source of energy in manufacturing plants and its consumption needs to be calculated. These compressors are designed to perform at maximum performance while reducing electricity costs. Air receivers are used to reduce the frequency of starts, thereby avoiding events such as grid outages and energy waste.

Improved Air Quality

Damp air is damaging to the processes going on in the production line and it affects the quality of the end products. The air tank in these compressors is built-in and functions as the first stage separator where moisture and other large contaminants such as rust settle at the compressor bottom. This relieves the subsequent working filters and enhances the general quality of compressed air.

Compact and Space-Saving

Today there is a requirement for a compact structure in manufacturing facilities. Tank Mounted Screw Air Compressors have a small and integrated structure of the compressor and the storage tank to increase floor space utilization while keeping optimum performance.

Low Maintenance Costs

These compressors have few mechanical parts and are designed to be easily maintained. Due to the unique design, the air end and motor can be serviced separately, so repair time is shorter, thus reducing costs. This makes them suitable for high-demand industries where long shutdowns may not be possible.

Why Tank Mounted Screw Air Compressors?

Enhanced Efficiency

The Tank Mounted Screw Air Compressors are built with efficiency in mind, for continuous or intermittent usage. The screw compression technology guarantees high performance with low energy entropy characteristics.

Longevity and Durability

The high-risk nature of production plants requires robust structures and equipment. These compressors are designed to be durable in harsh environments while providing long service with minimal maintenance.

Intelligent Control System

The available Tank Mounted Screw Air Compressors of today are designed with an intelligent control panel. Such systems, for example, control the pressure and temperature of the exhaust, frequency fluctuations, etc., at the same time and prevent much more expensive failures.

Cost Savings

These contain long-term benefits starting from energy efficiency and moving to the lower costs of maintenance as compared to other brands of compressors. They help to attain a higher return on investment by enhancing air quality as well as reducing equipment downtime.

Selection Criteria for a Tank Mounted Screw Air Compressor for the Manufacturing Process

Specifically, the type of compressor to be used largely determines the performance of the manufacturing process. Here are the key factors to consider:

Determine Your Air Demand

Consider the level of compressed air utilization by your production work processes. Determine how many cubic feet per minute (CFM) or cubic meters per minute your machinery requires to run and the pressure that goes with it.

Consider the Compressor Size

Choose a compressor that meets your air needs. But don’t choose a compressor that is too big or too small. Large compressors use more energy, while small compressors are inefficient. This will cause premature wear on the compressor and its peripherals.

Assess the Installation of Space

Check the amount of space in your facility and ensure that you choose the right compressor that will take up minimal space in the facility.

Prioritize Durability

Considering conditions in manufacture can be rigid, ensure you select a compressor made with a sturdy build and well-developed components. Choose models with warranties to increase the rate of efficient future work.

Applications of Tank Mounted Screw Air Compressors in Manufacturing

It’s used in manufacturing in areas such as:

Tank Mounted Screw Air Compressors are versatile and cater to various manufacturing needs, such as:

• Assembly Lines: Small scale for Operating power tools and equipment used for production purposes.

• Packaging: Precise in operations that involve sealing, filling, and labeling to achieve the most appropriate results.

• Automotive Industry: Accompanying spray painting, tire inflation, and instrumental jobs.

• Textile Manufacturing: Physically operating air-jet looms and operating other machinery.

• Electronics: Calling for Clean Air for Sensitive Equipped Establishment Processes.

Benefits of Tank Mounted Screw Air Compressors

• Reduced Downtime: When pressure varies, equipment frequently derails, resulting in disruptions.

• Improved Productivity: Proper air supply is very important so that operations can run without much interruption.

• Cost-Effective: Energy efficient design works to reduce bills especially that of electricity.

• Environmentally Friendly: Less use of energy is good for the environment this is sustainable.

Why VIBRANT Air Compressor?

VIBRANT is a renowned company in the air compressor marketplace; we deliver innovative services to meet your business requirements. Here’s why you should choose VIBRANT:

• Innovative Technology: The screw compression systems are the most sophisticated to ensure the best performance is achieved.

• Reliable Products: Long-term value-focused construction.

• Comprehensive Support: Consultancy services for installation and maintenance of different types of UPS.

• Customized Solutions: Manufactured to meet your production needs as a manufacturing company.

Conclusion

Tank Mounted Screw Air Compressors are the perfect solution for manufacturing industries that require stable, efficient, and high-quality compressed air. Their energy-saving design, compact build, and durable performance make them an invaluable asset to any manufacturing facility. By choosing the right compressor and partnering with a trusted provider like VIBRANT, you can ensure seamless operations, reduced costs, and improved productivity. Explore a VIBRANT range of Tank Mounted Screw Air Compressors today!