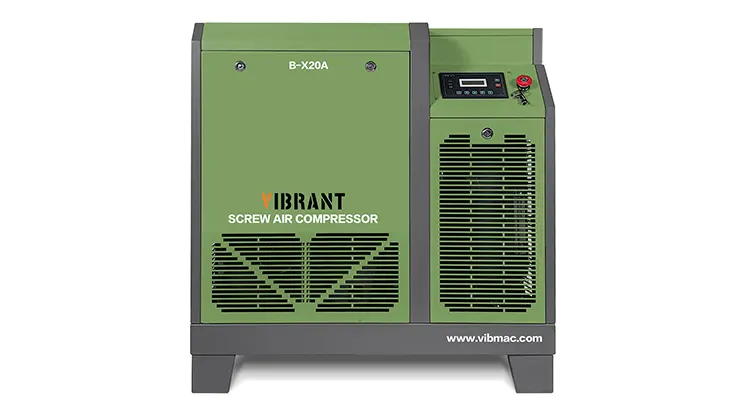

Product Introduction

We have a full range of air compressor models, piston air compressors, belt air compressors and screw air compressors are our main products. We provide customized options to ensure that customers are tailored to the best solution with efficiency, reliability and quiet operation.

The VIBRANT air compressor series combines innovative technology and strict quality standards, with a selection of high-quality components, and is committed to providing our customers with state-of-the-art and reliable air compressors to ensure the efficient and reliable operation of your business' equipment.

In the equipment manufacturing, textile and other industrial fields, there is a demand for air compressors with stable air pressure, rapid exhaust, large air output, we will provide different solutions according to the specific needs of different customers.

In the field of laser cutting, precision manufacturing, precise air pressure and exhaust volume control is more important, we accept customization, and strive to meet the different needs of customers.

In the food, chemical fiber, medical and pharmaceutical sectors, the quality of compressed air is even more important, and we are able to meet most of these requirements.

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 12.3

-

Power(KW/HP): 75/100

-

Dimension(mm): 1500*1230*1550

-

Noise dB(A): ≤82±2

-

Weigt(kg): 950

-

Pipe Diameter: G2

-

Startup Mode: Variable Frequency Start

-

Power Supply: Tree-phase 380V/50Hz , Can be customized

VIEW MORE

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 18/15.5/15.2/13/11

-

Power(KW/HP): 75/100

-

Weigt(kg): 1800

-

Pipe Diameter: G2 1/2

-

Dimension(mm): 2100*1440*1650

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

-

Dimension(mm): 1750*1240*1600

-

Noise dB(A): ≤70±2

-

Weigt(kg): 1096

-

Pipe Diameter: G2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8/1.0/1.3

-

Exhaust Volume(m³/min): 1.1/0.9/0.7

-

Power(KW/HP): 7.5/10

-

Dimension(mm): 800*600*860

-

Noise dB(A): ≤63±2

-

Weigt(kg): 112

-

Pipe Diameter: G1/2

-

Startup Mode: Variable Frequency Start

-

Power Supply: Tree-phase 380V/50Hz , Can be customized

VIEW MORE

-

Pressure(MPa): 1.6

-

FAD (m³/min): 9.0

-

Power(KW/HP): 75/100

-

Dimension(mm): 2100*1440*1650

-

Weigt(kg): 1300

-

Pipe Diameter: G1/2

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

-

Dimension(mm): 800*650*860

-

Weigt(kg): 180

-

Pipe Diameter: G1/2

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

-

Dimension(mm): 1500*670*1430

-

Weigt(kg): 355

-

Pipe Diameter: G1/2

-

Air Receiver(L): 220

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 1.6

-

FAD (m³/min): 11.2

-

Power(KW/HP): 90/125

-

Dimension(mm): 2600*1900*1890

-

Weigt(kg): 2600

-

Pipe Diameter: DN80

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8/1/1.3

-

FAD (m³/min): 12.3/10.8/9.1

-

Power(KW/HP): 75/100

-

Weigt(kg): 1500

-

Pipe Diameter: G2 1/2

-

Noise(dB): ≤80±2

-

Dimension(mm): 2100*1400*1650

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8/1/1.3

-

FAD (m³/min): 15.2/12.3/11.4

-

Power(KW/HP): 90/125

-

Weigt(kg): 1800

-

Pipe Diameter: DN65

-

Noise(dB): ≤82±2

-

Dimension(mm): 2250*1510*1850

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8/1/1.3

-

FAD (m³/min): 23/19.7/16

-

Power(KW/HP): 132/180

-

Weigt(kg): 3950

-

Pipe Diameter: DN100

-

Noise(dB): ≤82±2

-

Dimension(mm): 3250*2100*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8/1/1.3

-

FAD (m³/min): 2.3/2.1/1.7

-

Power(KW/HP): 15/20

-

Weigt(kg): 430

-

Pipe Diameter: G1

-

Noise(dB): ≤65±2

-

Dimension(mm): 1350*850*1110

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 12.4~9.1

-

Power(KW/HP): 75/100

-

Dimension(mm): 1700*1210*1550

-

Noise dB(A): ≤80±2

-

Weigt(kg): 1200

-

Pipe Diameter: G2 1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

-

Dimension(mm): 1150*750*960

-

Noise dB(A): ≤65±2

-

Weigt(kg): 320

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

-

Dimension(mm): 1150*750*960

-

Noise dB(A): ≤65±2

-

Weigt(kg): 340

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 3.5~2.4

-

Power(KW/HP): 22/30

-

Dimension(mm): 1350*850*1110

-

Noise dB(A): ≤72±2

-

Weigt(kg): 430

-

Pipe Diameter: G1

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 1.6

-

Exhaust Volume(m³/min): 0.5

-

Power(KW/HP): 7.5/10

-

Dimension(mm): 750*700*930

-

Drive Mode: Belt

-

Weigt(kg): 170

-

Pipe Diameter: G1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 2.3

-

Power(KW/HP): 15/20

-

Dimension(mm): 920*650*960

-

Drive Mode: Belt

-

Weigt(kg): 300

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 1.2-1.5

-

Exhaust Volume(m³/min): 0.7-0.63

-

Power(KW/HP): 7.5/10

-

Dimension(mm): 1500*540*1120

-

Drive Mode: Belt

-

Weigt(kg): 245

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Gas Tank(L): 250, available for customization

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

-

Dimension(mm): 1160*660*1660

-

Drive Mode: Belt

-

Weigt(kg): 340

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Gas Tank(L): 330, available for customization

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.0

-

Power(KW/HP): 7.5/10

-

Dimension(mm): 1400*510*1090

-

Noise dB(A): ≤68±2

-

Weigt(kg): 177

-

Pipe Diameter: G1/2

-

Startup Mode: Direct Start

-

Gas Tank(L): 230, available for customization

-

Power Supply: 380V/50HZ, or 220V, available for customization

VIEW MORE

-

Pressure(MPa): 0.8

-

Exhaust Volume(m3/min): 0.3

-

Power(KW/HP): 2.2/3

-

Dimension(mm): 1340*450*1030

-

Noise dB(A): ≤60±2

-

Weigt(kg): 116

-

Pipe Diameter: G1/2

-

Startup Mode: Direct Start

-

Gas Tank(L): 160, available for customization

-

Power Supply: 380V/50HZ, or 220V, available for customization

VIEW MORE

-

Pressure(MPa): 0.8

-

FAD(m³/min): 1.1

-

Power(KW/HP): 7.5/ 10

-

Dimension(mm): 1000*500*950

-

Noise dB(A): ≤62±2

-

Weigt(kg): 115

-

Pipe Diameter: G1/2*2

-

Startup Mode: Direct Start

-

Gas Tank(L): 230, available for customization

-

Power Supply: 380V/50HZ, or 220V, available for customization

VIEW MORE

-

Pressure(MPa): 0.8

-

Exhaust Volume(m3/min): 0.62

-

Power(KW/HP): 4/5.5

-

Dimension(mm): 1170*510*1090

-

Noise dB(A): ≤62±2

-

Weigt(kg): 154

-

Pipe Diameter: G1/2

-

Startup Mode: Direct Start

-

Gas Tank(L): 180, available for customization

-

Power Supply: 380V/50HZ, or 220V, available for customization

VIEW MORE

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.15

-

Power(KW/HP): 1.49

-

Air Receiver(L): 30

-

Dimension(mm): 620*270*570

-

Weigt(kg): 22.5

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.45

-

Power(KW/HP): 4.47

-

Air Receiver(L): 100

-

Dimension(mm): 1070*350*750

-

Weigt(kg): 68

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.6

-

Power(KW/HP): 4.5

-

Air Receiver(L): 160

-

Dimension(mm): 1360*450*950

-

Weigt(kg): 115

-

Pipe Diameter: G1/4, G1/2

-

Power Supply: 220V/380V 50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.8

-

Power(KW/HP): 6

-

Air Receiver(L): 180

-

Dimension(mm): 1550*450*950

-

Weigt(kg): 145

-

Pipe Diameter: G1/4, G1/2

-

Power Supply: 220V/380V 50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

-

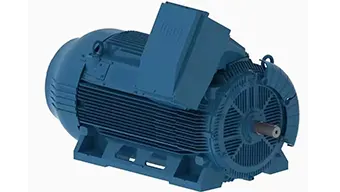

Power Range: 0.18 to 355Kw

-

Frequency: 50HZ

-

Efficiency: E2/GB3/GB2

-

Base: EC 80~355M/L

-

Voltage: Standard single voltage

-

Protection Level: IP55, IP56 available

-

Ambient Temperature: -20~40℃

-

Warranty: Two years

-

Cooling Method: TEFC/TEAO/TENV/TEBC

-

Certification: CE, CEL, UKCA, EAC, MASC

VIEW MORE

-

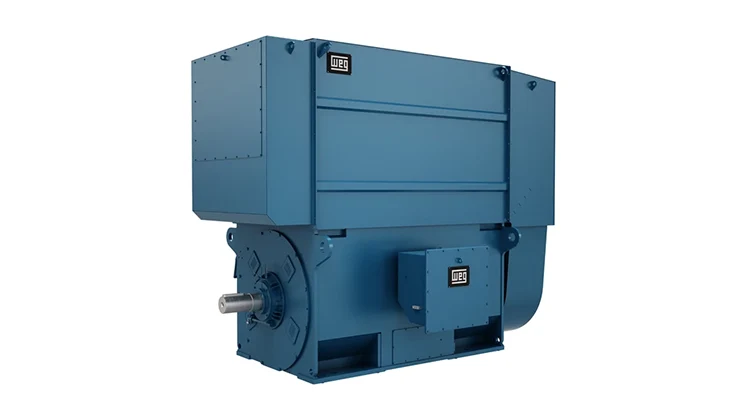

Output: up to 50,000 kW

-

Frequency: 50 or 60 Hz

-

Voltage: 220 to 13,800 V

-

Frame: 280 to 1800 (IEC)

-

Speed: 3,600 to 300 rpm

-

Rotor: Squirrel cage

-

Insulation Class: F or H

-

Mounting: Horizontal or vertical

-

Bearing: Ball bearing or sleeve bearing

-

Degree of Protection: IP23, IP24(W), IP55, IP56 or IP65

VIEW MORE

-

Power Range: 0.18 to 355Kw

-

Voltage: IE2/IE3/IE4/IE5

-

Frequency: 50HZ/60HZ

-

Base: IEC 80~355M/L

-

Ambient Temperature: -20~40℃

-

Warranty: 2 years

-

Protection Level: IP55, IP56/IP65/IP66 available

-

Cooling Method: TEFC/TEAO/TENV/TEBC

-

Certification: CE, CEL, UKCA, EAC, MASC

VIEW MORE

-

Output: 132 to 1.400 kW

-

Voltage: 380 to 11.000 V

-

Frequency: 50Hz/60 Hz

-

Frame: IEC 315 to 450

-

Cooling Method: TEFC/TEBC

-

Certification: CE

-

Startup Method: DOL/VFD

-

Enclosure: IC411 (TEFC)

-

Degree of Protection: IP55

VIEW MORE

Factory situation

We have strong production capital, more than 40000 square meters of factory space, independent R&D engineers and laboratories, and support field visits.

Quality Control

Each machine undergoes rigorous testing and inspection. From completion to delivery, the machine is subject to more than ten indicators, including pressure testing, operation testing, etc., to ensure that no unqualified machine will enter the market.

Energy-saving and efficient

Through the unified cooperation between the inverter and the motor, our products have achieved certain results in energy saving. Compared with the products on the market, our products have higher energy saving effects, with an average energy saving of 3%-5%.

-

What is the purpose of an air compressor?

-

For gas separation and refrigeration For synthesis and polymerization Hydrogenation and refining of oil Gas transportation Compressed air as power

-

Could you customize an air compressor to meet my needs?

-

Our factory supports customized service, you need to tell us the application scenario of the air compressor and your customized requirements in detail, such as the use environment, required pressure, exhaust volume, motor power, component brand requirements, etc., we can design and manufacture according to the requirements you provide, customized products need additional design and manufacturing time and cost, you need to tell us the estimated delivery time and budget, so that we can adjust the Supply Chain.

We will arrange professional engineers to design and keep communicating with you after we receive the specific requirements, the customized products will undergo strict quality control and testing during the production process to ensure that the products delivered to you fully meet your requirements.

-

What is the expected service life of the screw air compressors manufactured by your company?

-

Our company designs and produces high quality screw air compressors, which are durable and reliable, and their service life can reach more than 10 years if you maintain them regularly and use them properly.

Please follow our product manuals for proper operation and regular maintenance, such as regular replacement of air filters, oil filters, oil-air separators, lubricants, etc., to keep your air compressor in the best operating condition. If you have additional special requirements and operating conditions, we can provide advice and support.

We believe and promise that with our high quality products and professional services, the air compressor you purchase can realize the longest service life and optimal performance.

-

What parts of your screw air compressor need to be replaced and maintained regularly? How long is the time period?

-

Lubricating oil: the replacement cycle depends on the intensity of use of the compressor and environmental conditions, it is recommended that in the first 2 years of operation of the compressor, every 3-6 months to take oil samples to analyze in order to determine the replacement cycle; the initial operation of 500 hours need to replace the lubricating oil; under normal circumstances, every 3,000 hours to replace the system every 2 years of use to do a system cleaning, if the use of harsh environments, according to the circumstances of the shortened replacement cycle; The oil filter must be replaced at the same time when the oil is changed.

Oil filter: replace at the same time with lubricating oil.

Air filter: check and clean the air filter for the first 500 hours of operation, and replace it immediately if it is found to be broken; under normal circumstances, clean it every 1500 hours and replace it every 3000 hours. If the use environment is harsh, shorten the replacement cycle according to the situation.

Oil-air separator: make sure the system is free of pressure when replacing. The replacement cycle depends on the use conditions and oil quality. Under normal circumstances, replace it every 3000 hours and do a system cleaning every 2 years of use; if the use environment is harsh, shorten the replacement cycle according to the situation.

Cooling system: the cooler should be cleaned regularly, under normal circumstances, at least once a year to maintain cooling efficiency.

Safety valve: test it at least once a year to make sure it works properly.

-

Is the compressed air coming out of the oil-gas separator completely free of oil?

-

In order to ensure the separation effect, there are at least two points in the design of the oil and gas separator: one is the design of the eccentric inlet, so that the oil and gas mixture flows along the wall after entering the separator, and a large amount of liquid gathers at the wall, which is what everyone calls cyclone separation; Secondly, the separator is equipped with an oil-air separator cartridge with a precision of 1μm level. Suspended oil particles pass through the filter cartridge, are intercepted by the filter material, accumulate into large oil droplets, and then gather at the bottom of the cartridge, and then return to the lubricant system in the header through the return pipe in the concave area, which can filter out almost all the oil droplets in the air path.

-

What is a permanent magnet frequency conversion motor and its advantages?

-

Permanent magnet frequency conversion motor, abbreviated as PM VSD motor or PM inverter motor, is the most advanced type of motor used in the air compressor industry at present.

This kind of motor does not need reactive excitation current, which can significantly improve the power factor (up to 1, or even capacitive), reduce the stator current and stator resistance loss, and there is no rotor copper consumption in stable operation, which in turn can reduce the fan (the fan can even be removed for small-capacity motors) and the corresponding wind friction loss, and its efficiency can be increased by 2~8% compared with the same specification ordinary frequency conversion motor.

Moreover, the PM VSD motor adopts rare earth permanent magnet material , while the ordinary frequency conversion motor is an ordinary three-phase asynchronous motor.

The PM VSD motor can maintain high efficiency and power factor within the range of 25% to 120% of the rated load, and the frequency is automatically adjusted to change the power of the motor, which better matches the output power of the motor, and the effect of energy-saving is more obvious in the operation, and the efficiency of the working efficiency is higher than that of the same power of the ordinary frequency conversion motor by an average of 5% to 7%.

Permanent magnet motors do not require bearings and do not need to add lubricant, eliminating points of failure and have lower maintenance costs.

The PM VSD screw air compressor is driven by a special frequency converter, the starting current is very small, which has a good protection for the motor, and the motor is not easy to be burned.