WEG Three Phase Induction Motor

Compressed air moves with you!

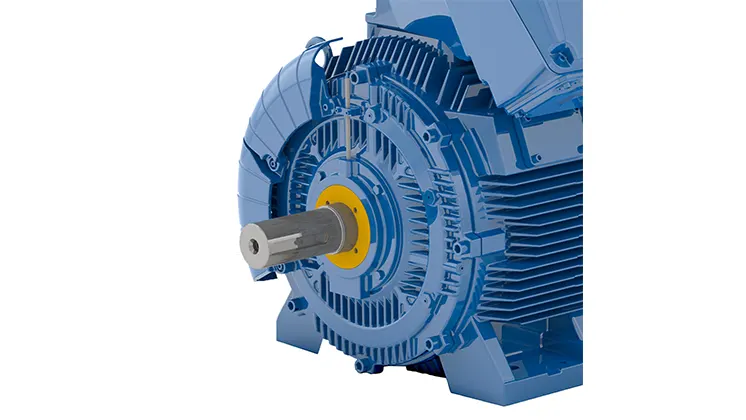

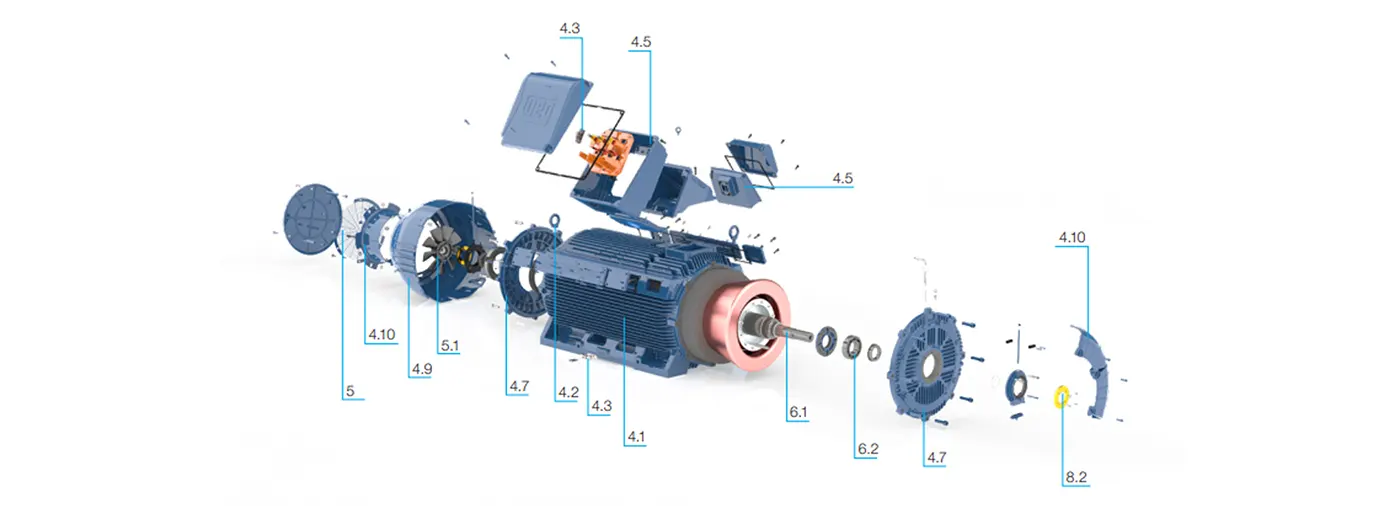

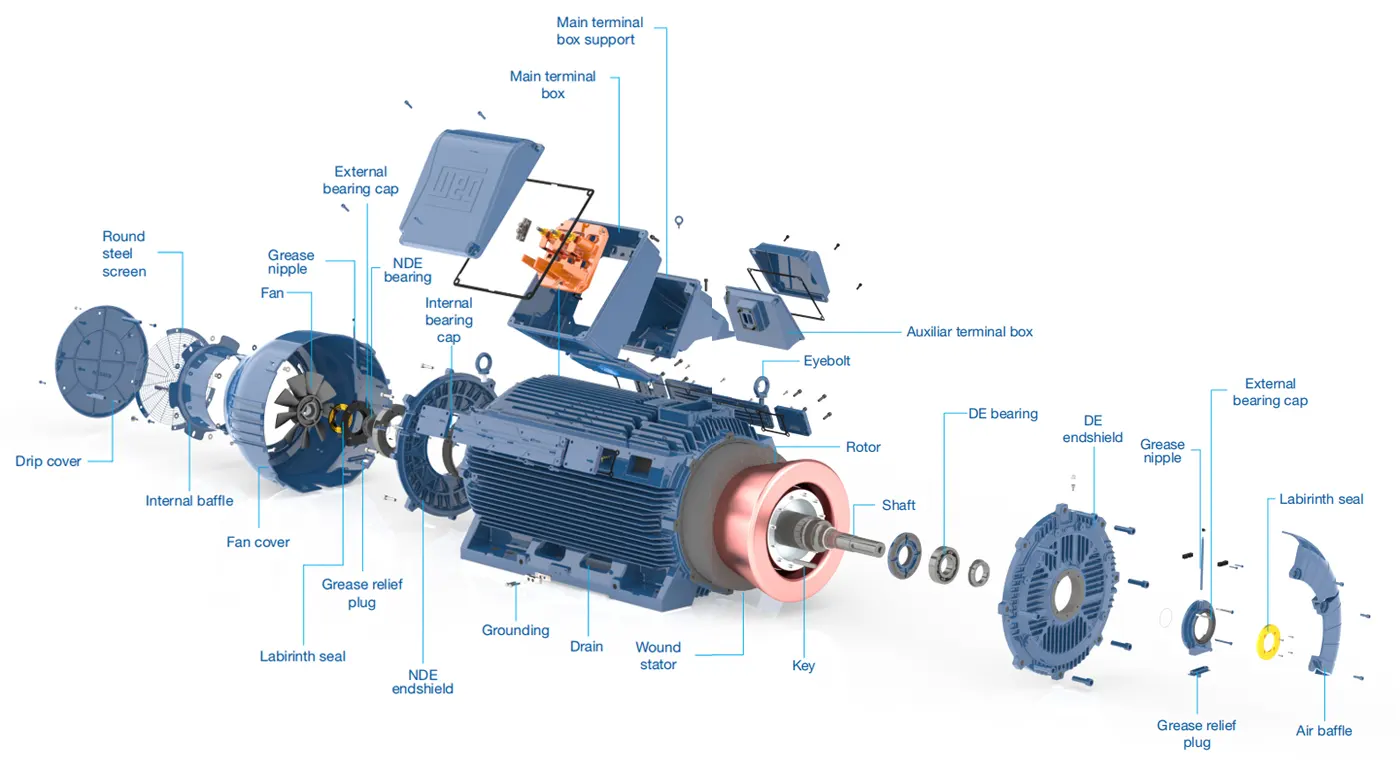

W51 HD Three-phase WEG Motor

The WEG W51 HD Three Phase three-induction motor is designed to withstand tough operating conditions commonly associated with high applications. Intended for use in high-efficiency tasks the motor comes with higher reliability and needs the least attention from the end user. Thus, its construction is robust and it can work at the maximum load in difficult conditions, being used for continuous-duty applications in manufacturing, processing, and automation industries.

W51 HD Three-phase WEG Motor

- Output: 132 to 1.400 kW

- Voltage: 380 to 11.000 V

- Frequency: 50Hz/60 Hz

- Frame: IEC 315 to 450

- Cooling Method: TEFC/TEBC

- Certification: CE

- Startup Method: DOL/VFD

- Enclosure: IC411 (TEFC)

- Degree of Protection: IP55

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

W60 Vertical Line Three

-

Rated output: 1,000 up to 7,500 kW

-

Number of poles: 10 up to 18

-

Frame: 630, 710 and 900

-

Voltage: 2,300 up to 13,800 V

-

Frequency: 50 or 60 Hz

-

Mounting: Vertical

VIEW MORE

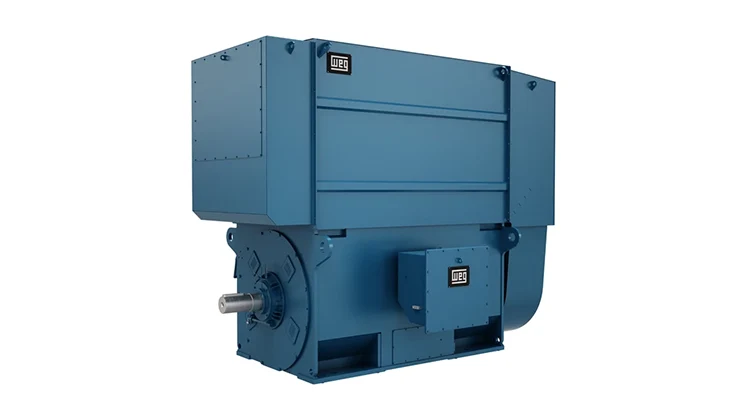

W60 Three-phase Induction WEG Motor

-

Rated output: 1,000 up to 7,500 kW

-

Number of poles: 10 up to 18

-

Frequency: 50 Hz/60 Hz

-

Frame: 630, 710 and 900

-

Voltage: 2,300 up to 13,800 V

-

Mounting: vertical

-

Service Factor: 1.00

-

Cooling Method: IC01, IC611 and IC81W

VIEW MORE

HGF-Three phase Induction Motor

-

Rated Output: 355 kW~2800 kW

-

Number of Poles: 2 ~12

-

Frequency: 50/60 Hz

-

Voltage: 2,300V~6,600 V

-

Service Factor: 1.00

-

Insulation Class: F (DT 80 K)

-

Degree of Protection: IP55

-

Mounting: Vertical or Horizontal

-

Enclosure Material: FC-200 cast iron

-

Cooling Method: TEFC (IC411) – Totally Enclosed Fan Cooled

VIEW MORE

MASTER Series Large Induction Motors

-

Output: up to 50,000 kW

-

Frequency: 50 or 60 Hz

-

Voltage: 220 to 13,800 V

-

Frame: 280 to 1800 (IEC)

-

Speed: 3,600 to 300 rpm

-

Rotor: Squirrel cage

-

Insulation Class: F or H

-

Mounting: Horizontal or vertical

-

Bearing: Ball bearing or sleeve bearing

-

Degree of Protection: IP23, IP24(W), IP55, IP56 or IP65

VIEW MORE

You May Also Like

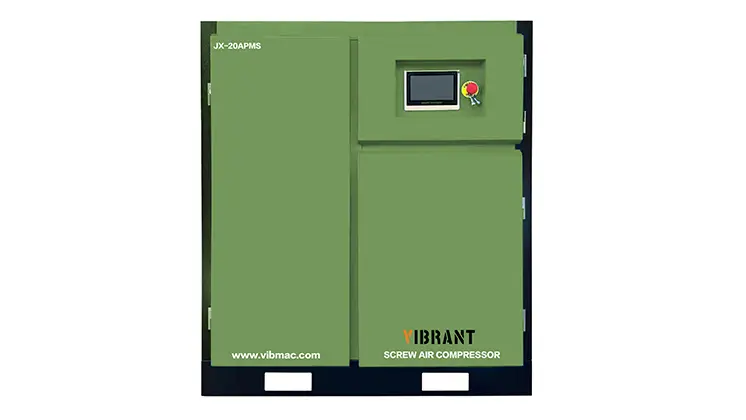

JX-20APMS-20HP/15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.3~1.7

-

Power(KW/HP): 15/20

VIEW MORE

JX-20AS-15KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

VIEW MORE

JX-15APMX-11KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

Z-G10A-7.5KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.0

-

Power(KW/HP): 7.5/10

VIEW MORE

Get In Touch