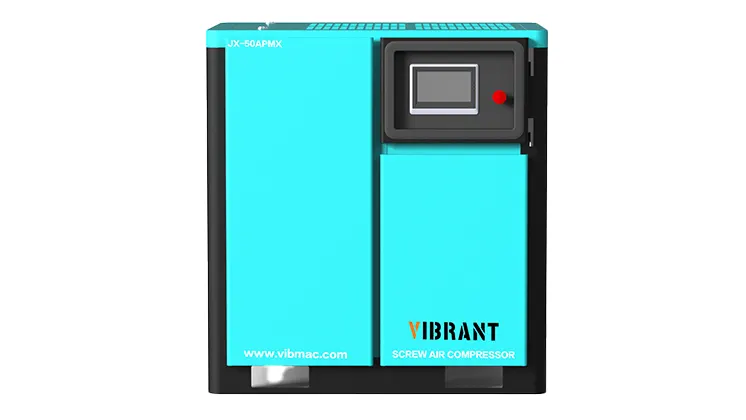

VSD Rotary Screw Air Compressor

Air compressors that can help companies solve their problems.

Permanent Magnet Frequency Conversion Screw Air Compressor

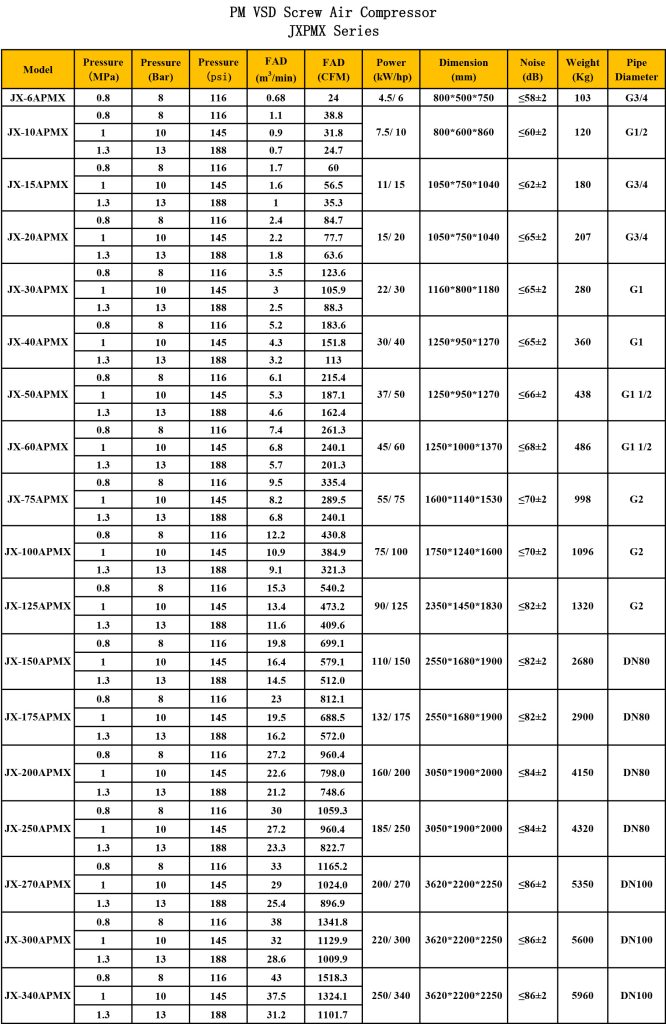

The VSD Rotary Screw Air Compressor – JX-50APMX-37KW is a low-cost, high-efficiency system that addresses most industries with air demands of varying speed ranges. This compressor has a motor capacity of 37kW (50 hp) and it provides air at the application rate and at various speeds needed to optimize the application and minimize power consumption. This motor design allows it to perform optimally under several conditions of operation.

JX-50APMX-37KW

- Pressure(MPa): 0.8~1.3

- Exhaust Volume(m³/min): 6.1~4.6

- Power(KW/HP): 37/50

- Dimension(mm): 1250*950*1290

- Noise dB(A): ≤66±2

- Weigt(kg): 438

- Pipe Diameter: G1 1/2

- Startup Mode: Frequency Conversion Start

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

-

Dimension(mm): 1750*1240*1600

-

Noise dB(A): ≤70±2

-

Weigt(kg): 1096

-

Pipe Diameter: G2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-75APMX-55KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 9.5~6.8

-

Power(KW/HP): 55/75

-

Dimension(mm): 1600*1140*1530

-

Noise dB(A): ≤70±2

-

Weigt(kg): 998

-

Pipe Diameter: G2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-50APMX-37KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 6.1~4.6

-

Power(KW/HP): 37/50

-

Dimension(mm): 1250*950*1290

-

Noise dB(A): ≤66±2

-

Weigt(kg): 438

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-60APMX-45KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 7.4~5.7

-

Power(KW/HP): 45/60

-

Dimension(mm): 1250*1000*1370

-

Noise dB(A): ≤68±2

-

Weigt(kg): 486

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

B-X15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

VIEW MORE

B-XG20AL

-

Pressure(MPa): 0.8-1.0

-

Exhaust Volume(m³/min): 2.3-2.1

-

Power(KW/HP): 15/20

VIEW MORE

JX-100APMS-100HP/75KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 12.3

-

Power(KW/HP): 75/100

VIEW MORE

JX-20APML

-

Pressure(MPa): 1.6/2.0

-

FAD (m³/min): 1.2/1.0

-

Power(KW/HP): 15/20

VIEW MORE

Get In Touch