Two Stage Air Compressor Pump

Perfect choice for air solution!

Two Stage Air Compressors

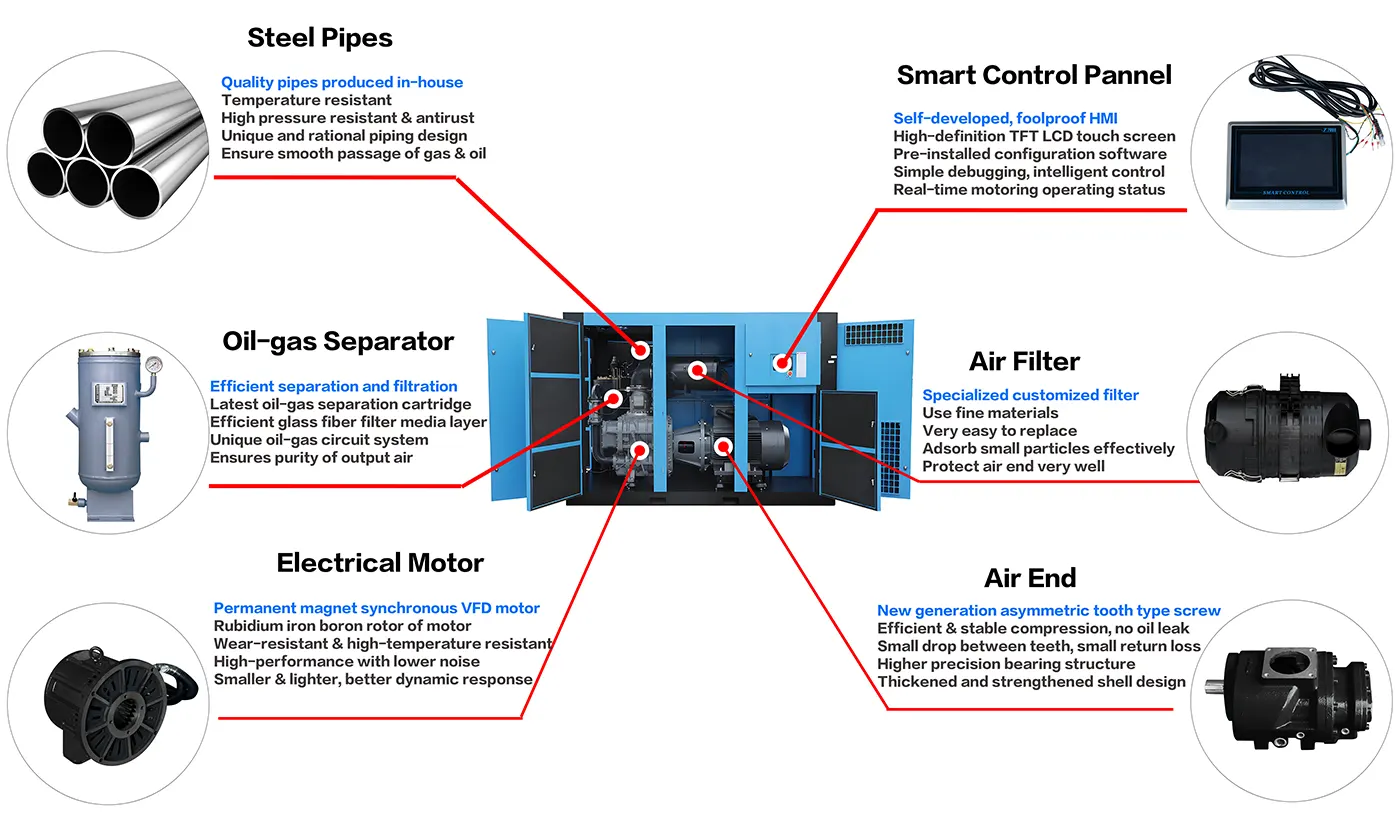

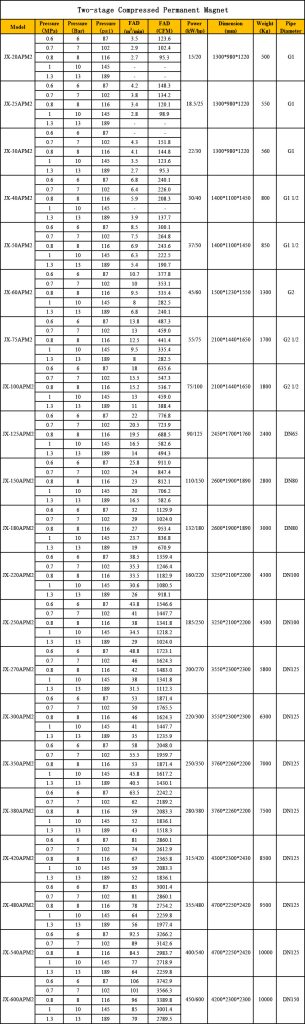

The JX-20APM2 Two Stage Air Compressor Pump is one of the most efficient and long-lasting products in the widening world of providing service in various industries in the present era. This optimized unit comes with multiple pressures to achieve the best outcome within the environments of small-scale production industries such as workshops.

JX-20APM2

- Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

- FAD (m³/min): 3.5/2.9/2.7

- Power(KW/HP): 15/20

- Weigt(kg): 500

- Pipe Diameter: G1

- Dimension(mm): 1300*980*1220

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-25APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 4.2/3.8/3.4/2.8

-

Power(KW/HP): 18.5/25

-

Weigt(kg): 550

-

Pipe Diameter: G1

-

Dimension(mm): 1300*980*1220

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-30APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 4.3/4.1/3.5/2.7

-

Power(KW/HP): 22/30

-

Weigt(kg): 560

-

Pipe Diameter: G1

-

Dimension(mm): 1300*980*1220

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-40APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 6.8/6.4/5.9/3.9

-

Power(KW/HP): 30/40

-

Weigt(kg): 800

-

Pipe Diameter: G1 1/2

-

Dimension(mm): 1400*1100*1450

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-50APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 8.5/7.5/6.9/6.3/5.4

-

Power(KW/HP): 37/50

-

Weigt(kg): 850

-

Pipe Diameter: G1 1/a2

-

Dimension(mm): 1400*1100*1450

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-15AS-11KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

JX-10APML

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

JX-10APMLT

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

Get In Touch