Twin Screw Air Compressor

Air compressors that can help companies solve their problems.

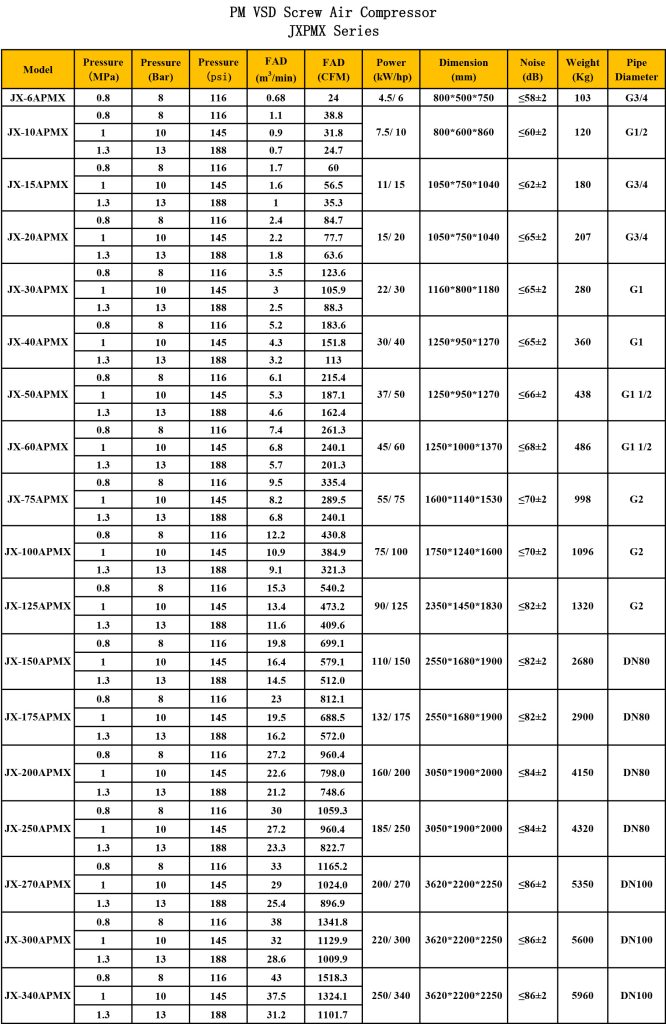

Permanent Magnet Frequency Conversion Screw Air Compressor

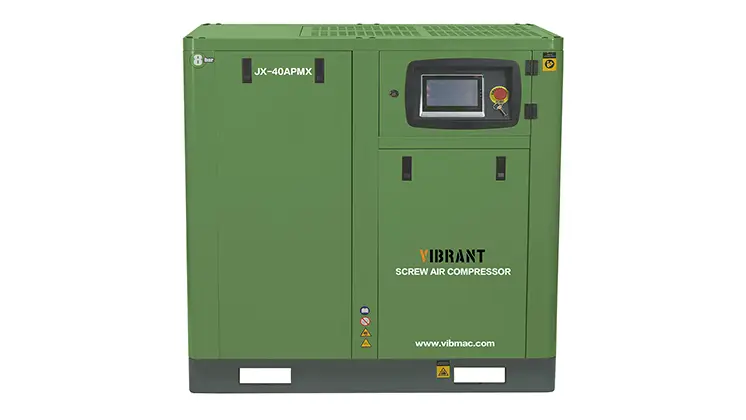

Twin Screw Air Compressor – JX-40APMX is a cost-effective, powerful air compressor with a single concept of twin screw compressor system used for industrial purposes. This air-cooled compressor works at a relatively low noise level, ideal for use where the noise generated must be restricted, and yet it has a high capacity to deliver in the process where this is required. Built of strong components and armed with a strong motor it guarantees continuous air provision for a vast majority of industrial purposes.

JX-40APMX-30KW

- Pressure(MPa): 0.8~1.3

- Exhaust Volume(m³/min): 5.2~3.2

- Power(KW/HP): 30/40

- Dimension(mm): 1250*950*1290

- Noise dB(A): ≤66±2

- Weigt(kg): 360

- Pipe Diameter: G1

- Startup Mode: Frequency Conversion Start

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

-

Dimension(mm): 1750*1240*1600

-

Noise dB(A): ≤70±2

-

Weigt(kg): 1096

-

Pipe Diameter: G2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-50APMX-37KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 6.1~4.6

-

Power(KW/HP): 37/50

-

Dimension(mm): 1250*950*1290

-

Noise dB(A): ≤66±2

-

Weigt(kg): 438

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-60APMX-45KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 7.4~5.7

-

Power(KW/HP): 45/60

-

Dimension(mm): 1250*1000*1370

-

Noise dB(A): ≤68±2

-

Weigt(kg): 486

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-75APMX-55KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 9.5~6.8

-

Power(KW/HP): 55/75

-

Dimension(mm): 1600*1140*1530

-

Noise dB(A): ≤70±2

-

Weigt(kg): 998

-

Pipe Diameter: G2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

B-X20A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 2.3

-

Power(KW/HP): 15/20

VIEW MORE

B-XG5.5A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 0.48

-

Power(KW/HP): 4/5.5

VIEW MORE

JX-100APMS-100HP/75KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 12.3

-

Power(KW/HP): 75/100

VIEW MORE

JX-100AS-100HP/75KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 12.4~9.1

-

Power(KW/HP): 75/100

VIEW MORE

Get In Touch