Rotary Screw Air Compressor Portable

Compressed air moves with you!

Portable Rotary Screw Air Compressor

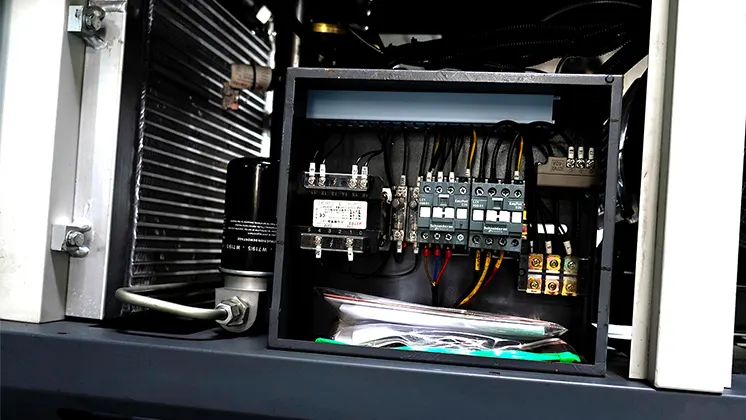

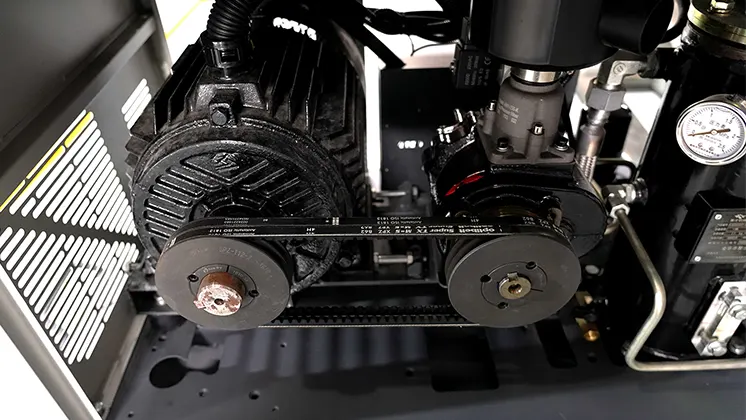

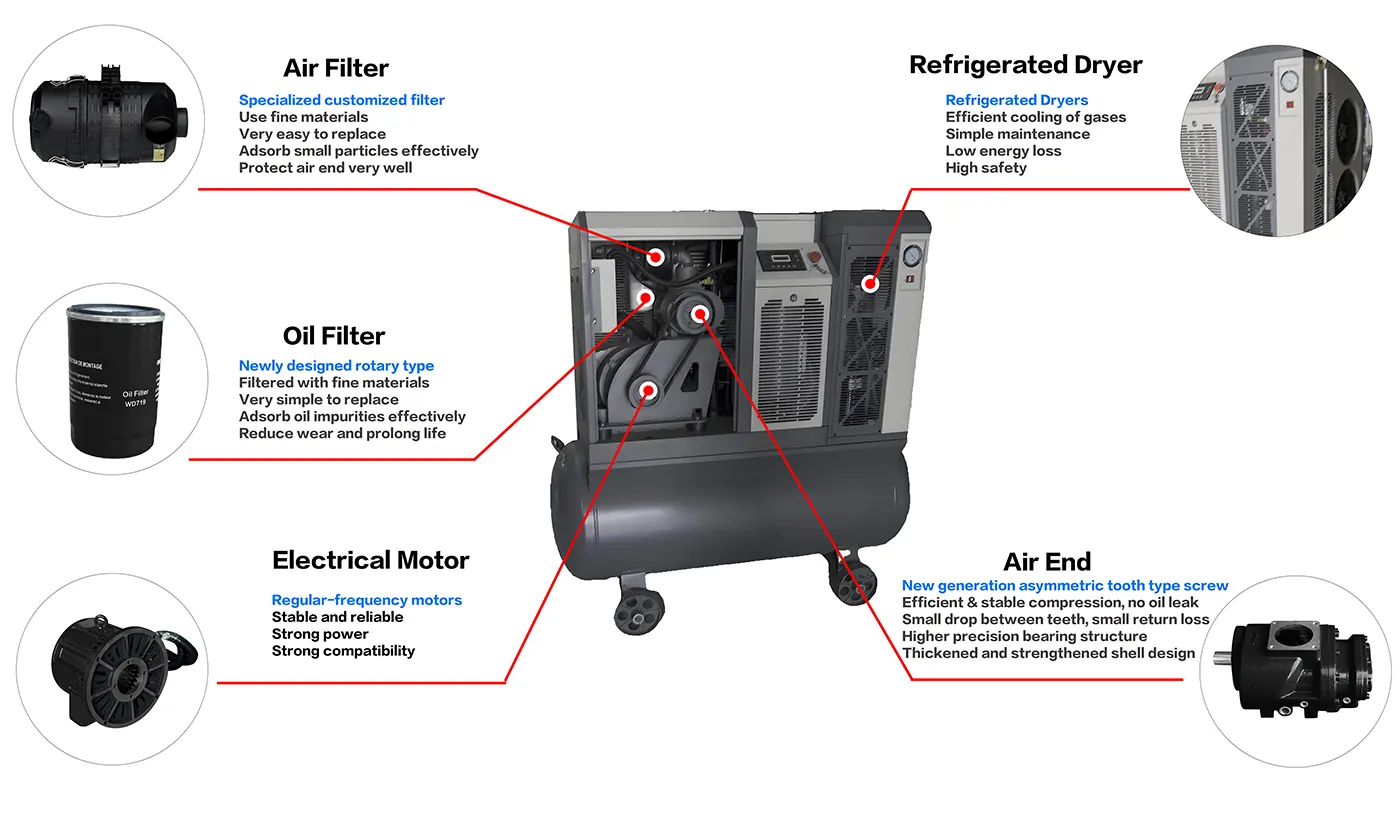

The B-XG10AL Rotary Screw Air Compressor is all about a bond that achieves the best of portability and power all in one bond. With a 10 HP motor and featuring a 300L air receiver tank, it is a 4 in 1 efficient compressor designed for the uncompromising industrial and on-site requirements. It uses rotary screw technology for the airflow making it very reliable and it is very challenging to carry due to its design. When it comes to construction sites or automobile repair garages, automotive workshops, or industrial maintenance, the B-XG10AL can deliver its best performance with far less noise and easier servicing.

B-XG10AL

- Pressure(MPa): 1.2-1.5

- Exhaust Volume(m³/min): 0.7-0.63

- Power(KW/HP): 7.5/10

- Dimension(mm): 1550*580*1230

- Drive Mode: Belt

- Weigt(kg): 320

- Pipe Diameter: G3/4

- Startup Mode: Direct Start

- Gas Tank(L): 300, available for customization

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

B-XG10A

-

Pressure(MPa): 1.2-1.5

-

Exhaust Volume(m³/min): 0.7-0.63

-

Power(KW/HP): 7.5/10

-

Dimension(mm): 1500*540*1120

-

Drive Mode: Belt

-

Weigt(kg): 245

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Gas Tank(L): 250, available for customization

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

B-XG15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

-

Dimension(mm): 1160*660*1660

-

Drive Mode: Belt

-

Weigt(kg): 340

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Gas Tank(L): 330, available for customization

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

B-XG5.5A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 0.48

-

Power(KW/HP): 4/5.5

-

Dimension(mm): 1250*480*1060

-

Drive Mode: Belt

-

Weigt(kg): 188

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Gas Tank(L): 210, available for customization

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

B-XG7.5A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 0.67

-

Power(KW/HP): 5.5/7.5

-

Dimension(mm): 1250*480*1060

-

Drive Mode: Belt

-

Weigt(kg): 190

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Gas Tank(L): 210, Available for Customization

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

JX-20APMS-20HP/15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.3~1.7

-

Power(KW/HP): 15/20

VIEW MORE

JX-20AS-15KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

VIEW MORE

JX-15APMX-11KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

Z-G10A-7.5KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.0

-

Power(KW/HP): 7.5/10

VIEW MORE

Get In Touch