Eagle 5-Hp 60-Gallon Single-Stage Air Compressor (PM VSD)

Air compressors that can help companies solve their problems.

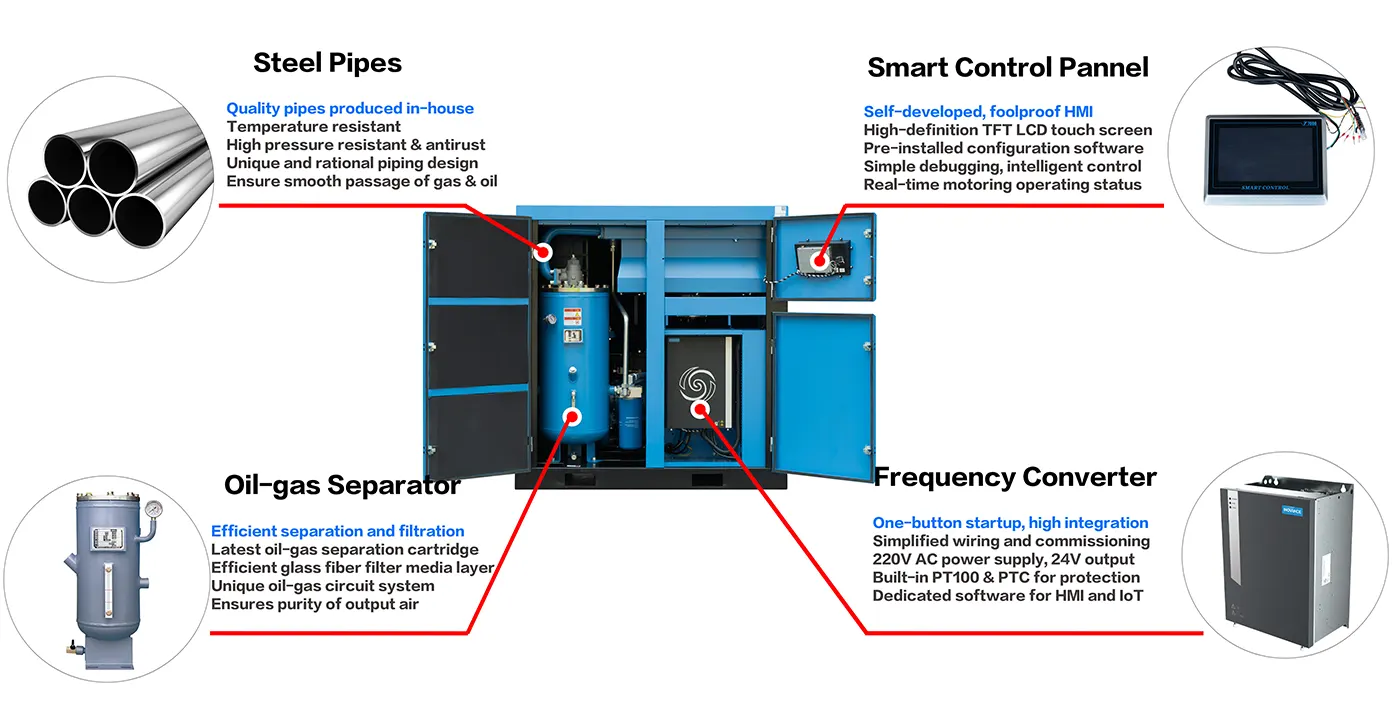

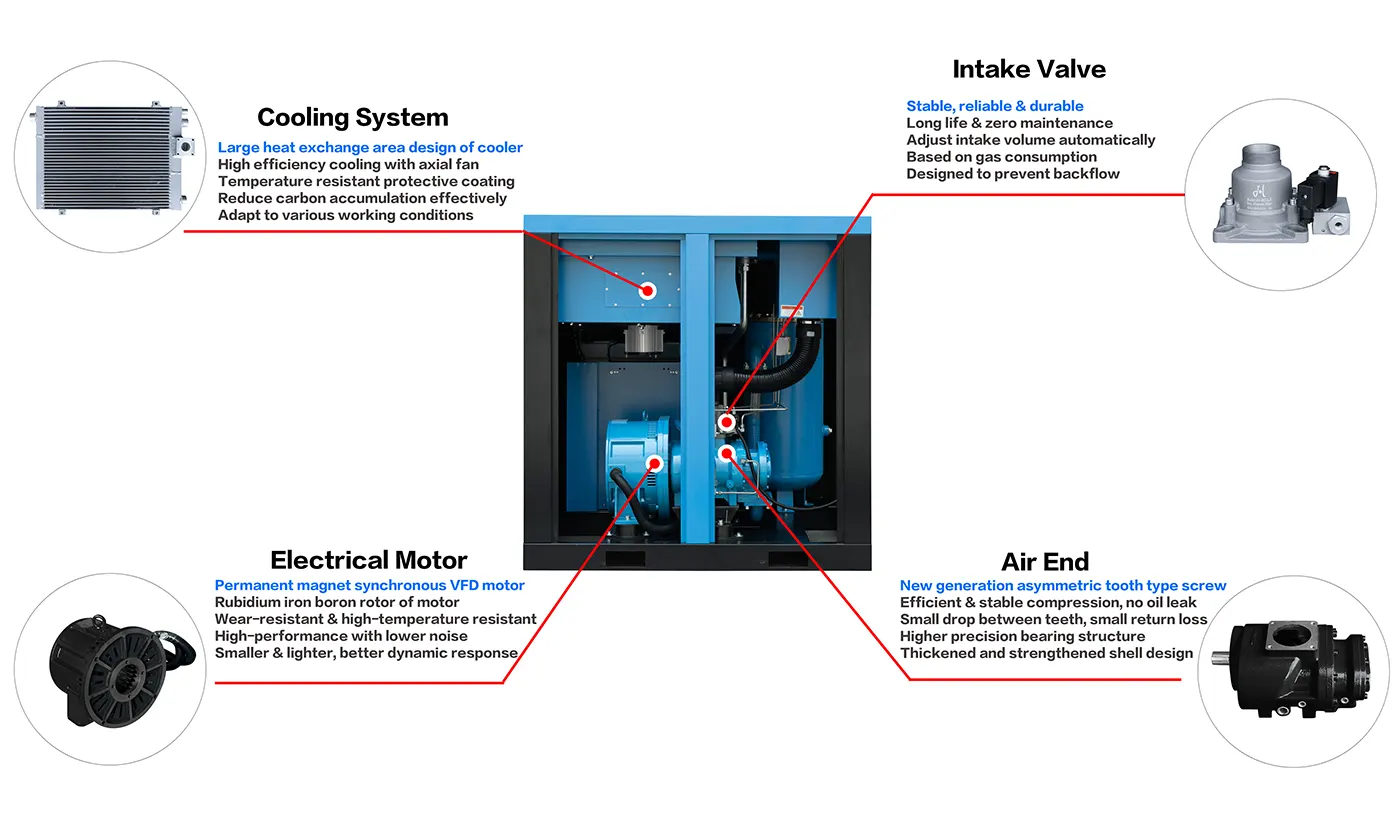

Permanent Magnet Frequency Conversion Screw Air Compressor

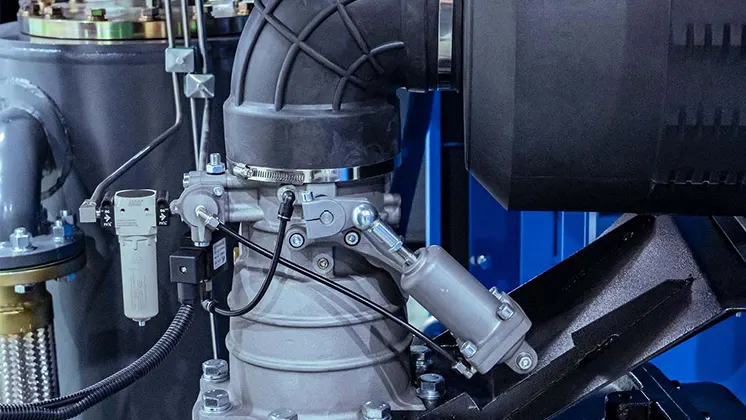

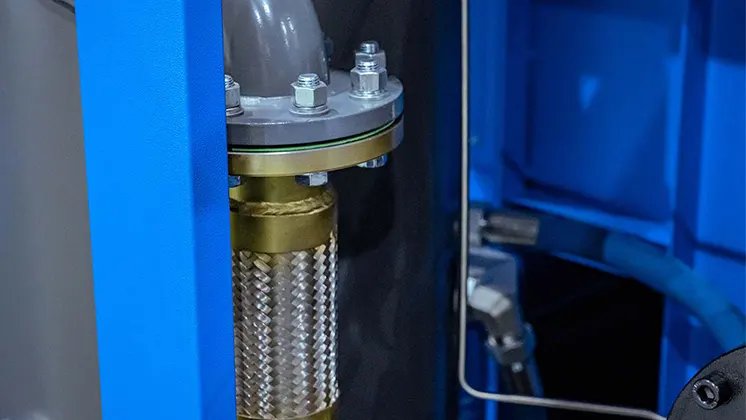

This brand new air compressor model is a highly efficient air compressor ideal for industrial and heavy usage applications, without compromising on quality and efficiency. This compressor was designed to provide great amounts of air and yet have low intonation levels. That’s why its air-cooled system and a direct drive connection guarantee the maximum productivity and durability of the tool when used in harsh conditions.

JX-40APMS-40HP/30KW

- Pressure(MPa): 0.8~1.3

- Exhaust Volume(m³/min): 4.7~3.1

- Power(KW/HP): 30/40

- Dimension(mm): 1100*850*1110

- Noise dB(A): ≤75±2

- Weigt(kg): 450

- Pipe Diameter: G1

- Startup Mode: Frequency Conversion Start

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-100APMS-100HP/75KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 12.3

-

Power(KW/HP): 75/100

-

Dimension(mm): 1500*1230*1550

-

Noise dB(A): ≤82±2

-

Weigt(kg): 950

-

Pipe Diameter: G2

-

Startup Mode: Variable Frequency Start

-

Power Supply: Tree-phase 380V/50Hz , Can be customized

VIEW MORE

JX-75APMS-75HP/55KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 9.4~6.2

-

Power(KW/HP): 55/75

-

Dimension(mm): 1500*1230*1550

-

Noise dB(A): ≤80±2

-

Weigt(kg): 850

-

Pipe Diameter: G2 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

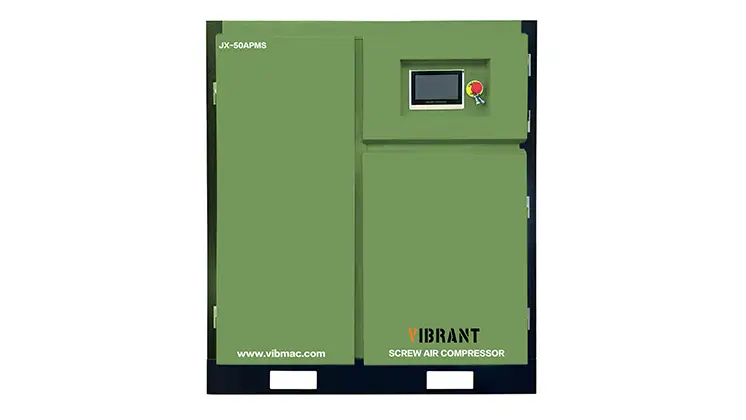

JX-50APMS-50HP/37KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 6.4~4.7

-

Power(KW/HP): 37/50

-

Dimension(mm): 1200*1000*1350

-

Noise dB(A): ≤77±2

-

Weigt(kg): 600

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

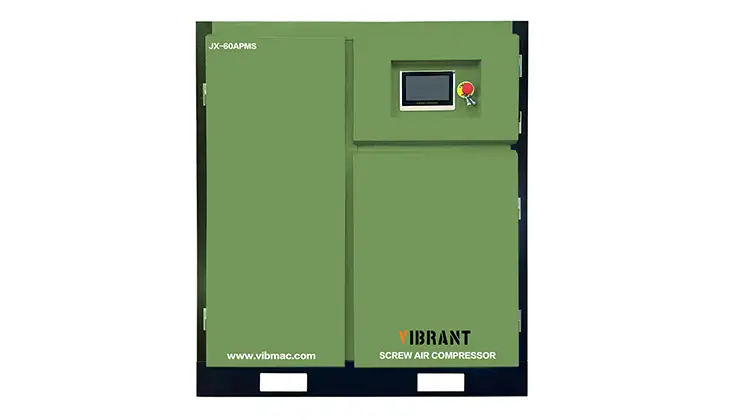

JX-60APMS-60HP-45KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 7.3~5.5

-

Power(KW/HP): 45/60

-

Dimension(mm): 1200*1000*1350

-

Noise dB(A): ≤78±2

-

Weigt(kg): 700

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

B-XG10AL

-

Pressure(MPa): 1.2-1.5

-

Exhaust Volume(m³/min): 0.7-0.63

-

Power(KW/HP): 7.5/10

VIEW MORE

JX-100APML2

-

Pressure(MPa): 1.6

-

FAD (m³/min): 9.0

-

Power(KW/HP): 75/100

VIEW MORE

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-100AS-100HP/75KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 12.4~9.1

-

Power(KW/HP): 75/100

VIEW MORE

Get In Touch

-1-696x1024.jpg)