Best Oil Free Air Compressor

Air compressors that can help companies solve their problems.

Oil Free Air Compressor

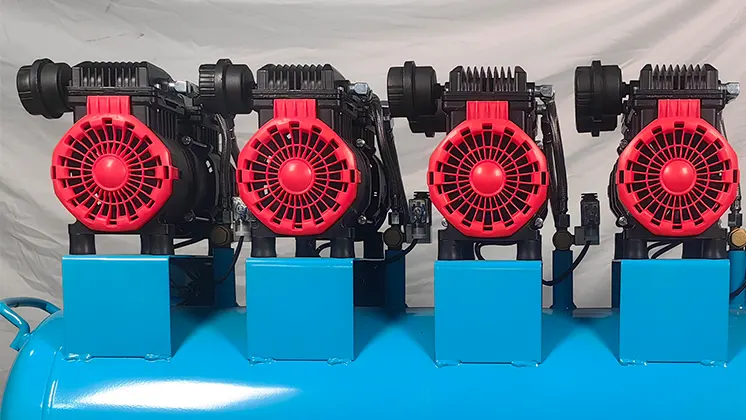

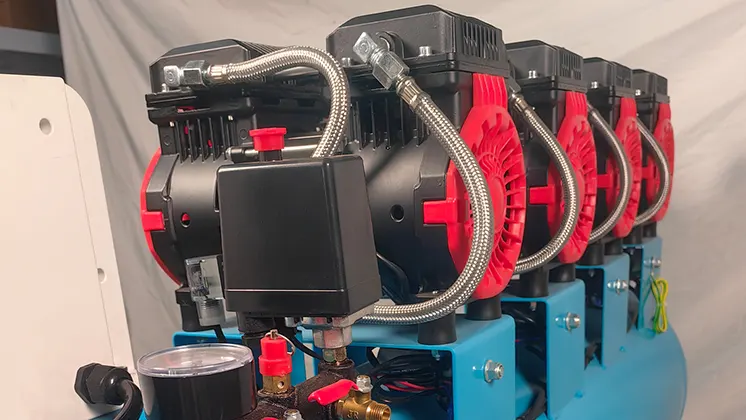

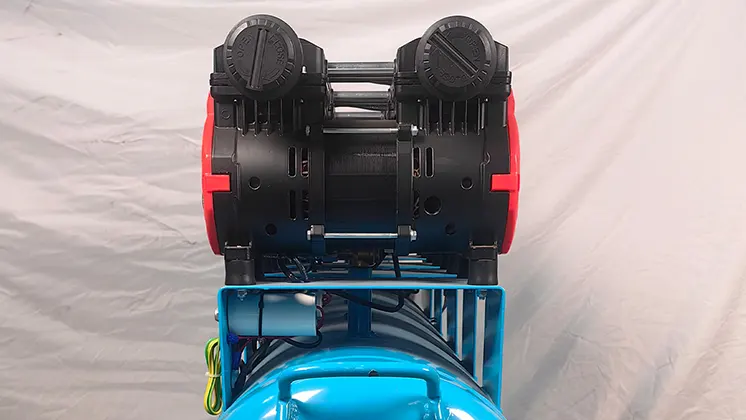

A multifunctional and highly performing oil-free air compressor called VP-14904-120 is the best for several industries that require clean air provision without incorporation of oil into the air supply line. It has a 120-liter air receiver tank and a 5.96 kW (8 HP) motor, for cool, quiet, and accurate air delivery most applications require. The direct drive system described above and industrial frequency startups enhance their low-maintenance operations in the power-on mode.

VP-14904-120

- Pressure(MPa): 0.8

- FAD(m³/min): 0.6

- Power(KW/HP): 5.96

- Air Receiver(L): 120

- Dimension(mm): 1300*400*760

- Weigt(kg): 90

- Pipe Diameter: G1/4, G1/2

- Power Supply: 220V/50Hz

- Drive Mode: Direct Drive

- Startup Mode: Industrial Frequency Startup

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

VP-14903-100

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.45

-

Power(KW/HP): 4.47

-

Air Receiver(L): 100

-

Dimension(mm): 1070*350*750

-

Weigt(kg): 68

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-14901-30

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.15

-

Power(KW/HP): 1.49

-

Air Receiver(L): 30

-

Dimension(mm): 620*270*570

-

Weigt(kg): 22.5

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-14904-120

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.6

-

Power(KW/HP): 5.96

-

Air Receiver(L): 120

-

Dimension(mm): 1300*400*760

-

Weigt(kg): 90

-

Pipe Diameter: G1/4, G1/2

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-6001-30

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.08

-

Power(KW/HP): 0.6

-

Air Receiver(L): 30

-

Dimension(mm): 620*270*570

-

Weigt(kg): 21

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

You May Also Like

JX-20APMS-20HP/15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.3~1.7

-

Power(KW/HP): 15/20

VIEW MORE

JX-20APMX-15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.4~1.8

-

Power(KW/HP): 15/20

VIEW MORE

JX-20AS-15KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

VIEW MORE

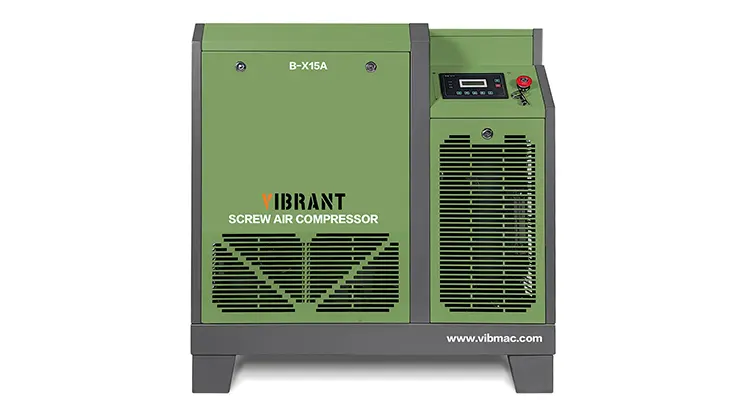

B-X15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

VIEW MORE

Get In Touch