Air Compressor Tank

Air compressors that can help companies solve their problems.

Fixed Speed Air Compressor

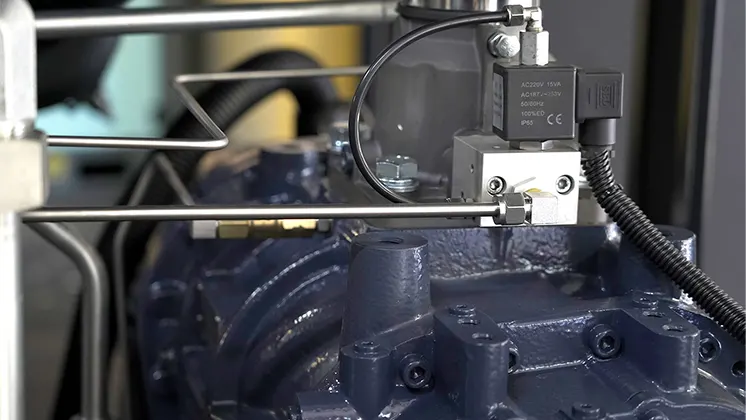

The Air Compressor Tank – JX-50AS-50HP-37KW is built for storing large volumes of compressed air to support industrial air compressor plants. This air compressor tank is well suited for use with 50 HP, or 37 kW, compressors and affords sufficient air storage volume to optimize and maintain compressor performance. It is designed for durability hence ideal for several uses in industries as it provides reliability for operations in high-demand areas.

JX-50AS-50HP-37KW

- Pressure(MPa): 0.7~1.3

- Exhaust Volume(m³/min): 6.4~4.7

- Power(KW/HP): 37/50

- Dimension(mm): 1500*1000*1350

- Noise dB(A): ≤78±2

- Weigt(kg): 650

- Pipe Diameter: G1 1/2

- Startup Mode: Direct Start

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-100AS-100HP/75KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 12.4~9.1

-

Power(KW/HP): 75/100

-

Dimension(mm): 1700*1210*1550

-

Noise dB(A): ≤80±2

-

Weigt(kg): 1200

-

Pipe Diameter: G2 1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-40AS-40HP-30KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 4.7~3.1

-

Power(KW/HP): 30/40

-

Dimension(mm): 1350*850*1110

-

Noise dB(A): ≤72±2

-

Weigt(kg): 460

-

Pipe Diameter: G1

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-60AS-60HP-45KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 7.3~6.2

-

Power(KW/HP): 45/60

-

Dimension(mm): 1500*1000*1350

-

Noise dB(A): ≤78±2

-

Weigt(kg): 700

-

Pipe Diameter: G1 1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

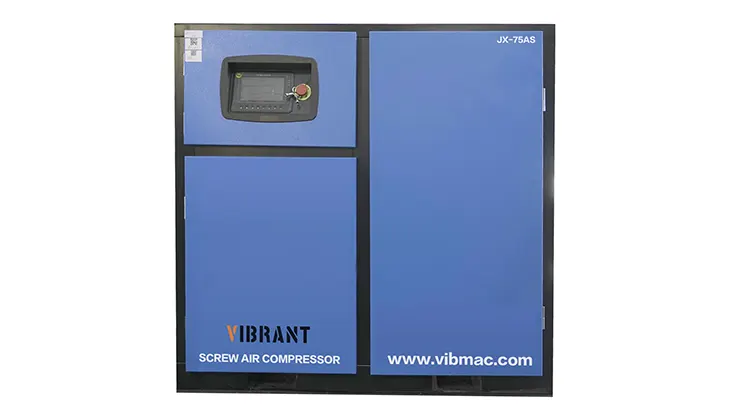

JX-75AS-55KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 9.4~6.1

-

Power(KW/HP): 55/75

-

Dimension(mm): 1700*1210*1550

-

Noise dB(A): ≤80±2

-

Weigt(kg): 1100

-

Pipe Diameter: G2 1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

B-X10A-16

-

Pressure(MPa): 1.6

-

Exhaust Volume(m³/min): 0.5

-

Power(KW/HP): 7.5/10

VIEW MORE

JX-100APML2

-

Pressure(MPa): 1.6

-

FAD (m³/min): 9.0

-

Power(KW/HP): 75/100

VIEW MORE

JX-10APMLT

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

JXL-100APM

-

Pressure(MPa): 0.2/0.3/0.4/0.5

-

FAD (m³/min): 27/24/20.5/17

-

Power(KW/HP): 75/100

VIEW MORE

Get In Touch