Air Compressor Pump Two Stage

The JX-40APM2 Air Compressor Pump Two Stage is a robust, nevertheless, portable air compressor meant for specific heavy-use industrial applications that require steady and high-quality airflow. This tool has a two-step compression system which makes it appropriate for operations that require different amounts of pressure and airflow all through delivering consistent outputs in various operations.

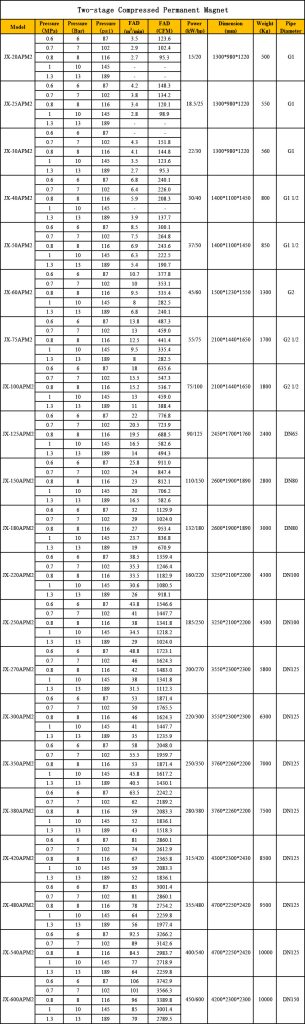

- Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

- FAD (m³/min): 6.8/6.4/5.9/3.9

- Power(KW/HP): 30/40

- Weigt(kg): 800

- Pipe Diameter: G1 1/2

- Dimension(mm): 1400*1100*1450

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

This machine is available with different pressure ranges of between 0.6 MPa and 1.3 MPa or 87 psi and 189 psi to meet different industrial requirements. It also provides Free Air Delivery (FAD) up to 6.8 m³/min (240.1 CFM) at 0.6 MPA that will deliver uninterrupted air for operation in a wide range of applications. Equipped with a 30 kW (40 hp) motor, this air compressor features both high reliability and productivity. The unit sizes are a width of 1400mm and depth of 1100mm and a height of 1450mm, and the product or unit weighs approximately 800 Kgs and could be said to be compact enough especially for industrial use.

- Two-Stage Compression Efficiency: The two-stage system enhances general efficiency and guarantees optimum performance for challenging applications that need a steady supply of air pressure.

- Flexible Pressure Settings: Equipped with an operating pressure ranging from 0.6 MPa to 1.3 MPa, the possible applications of the fryer are flexible.

- Reliable Air Delivery: Capable of providing a maximum FAD of 6.8m³/min (240.1 CFM) at 0.6 MPa, it is possible to maintain the compressed air at optimum levels even in extreme operating conditions.

- Sturdy and Compact Design: The main and high-lasting metal body of the compressor makes it more durable to be used in different industries and also can be installed easily in industries having less area.

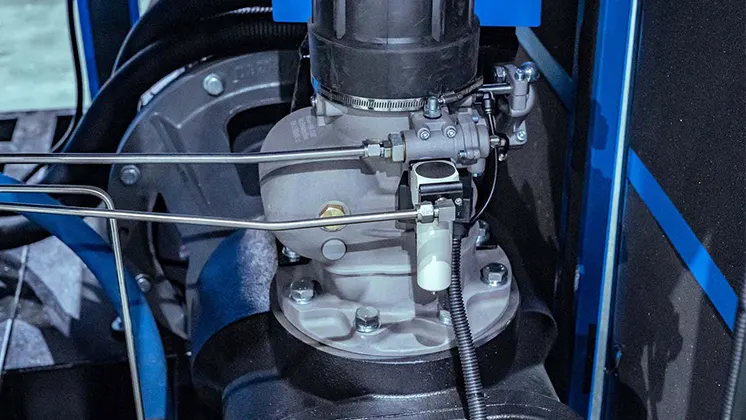

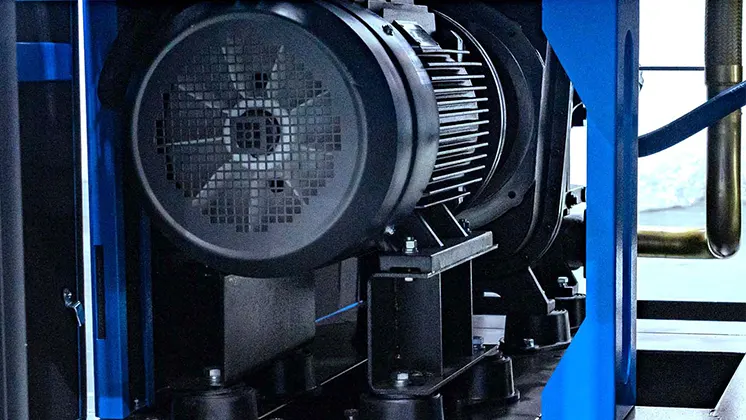

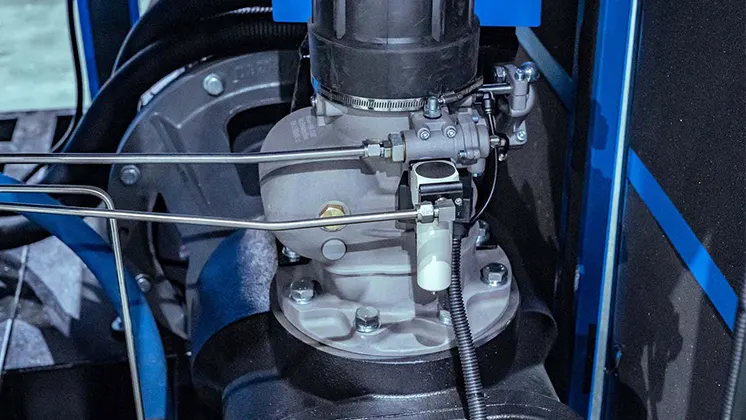

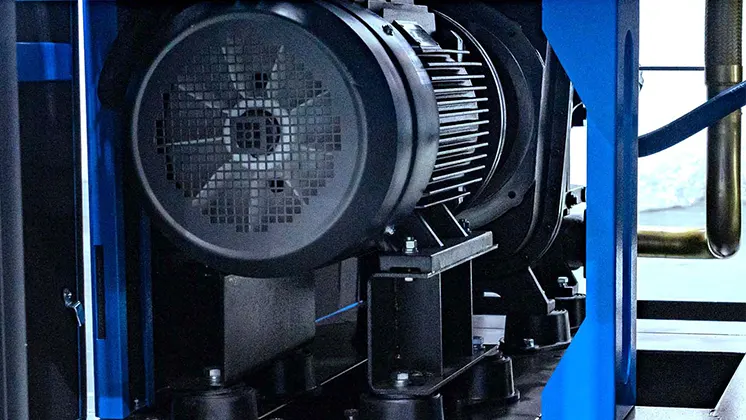

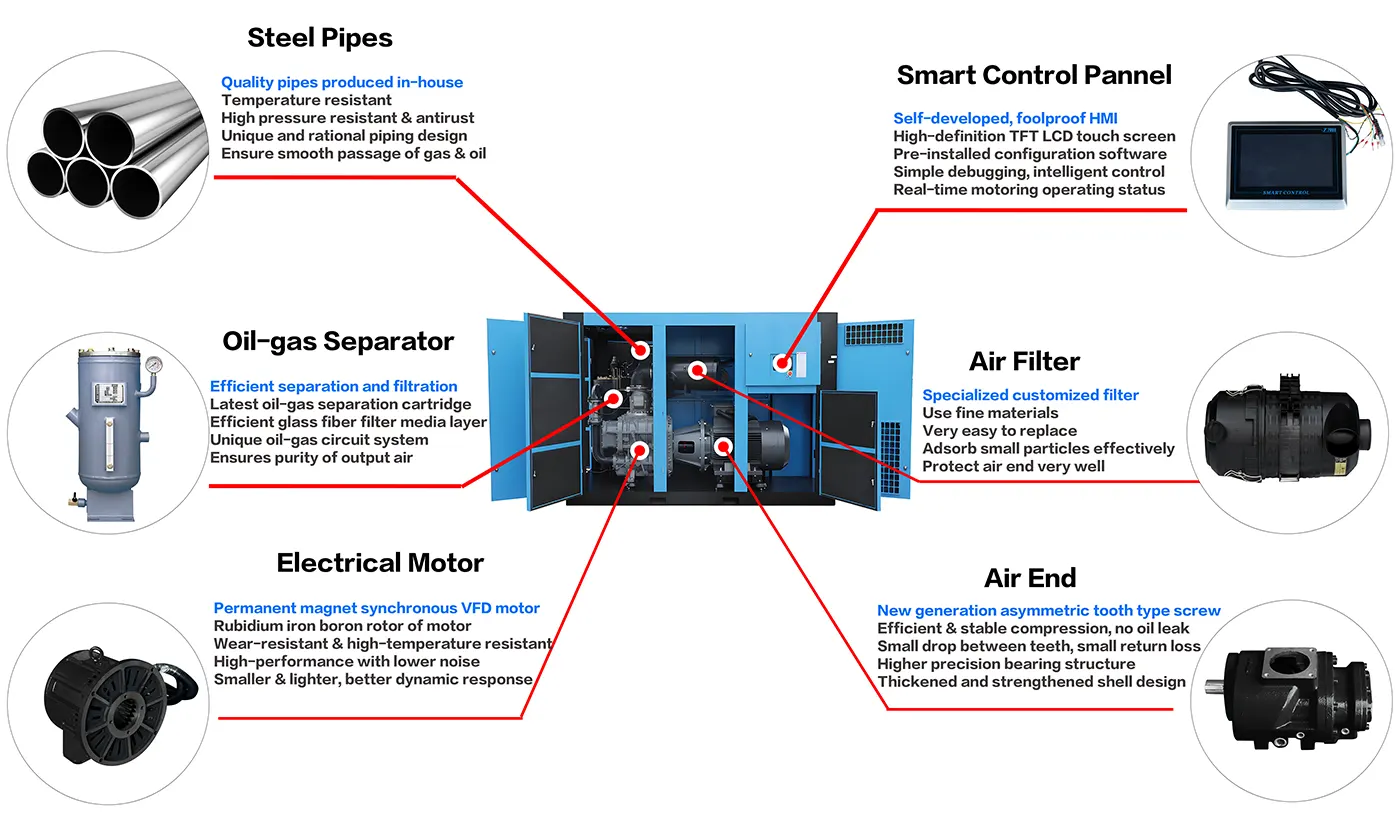

- Compressor Unit: Brings the ability to perform efficient two-stage air compression that guarantees a large amount of air production for industrial purposes.

- Cooling System: Guarantees that the compressor runs at a suitable temperature so that it does not overheat in the course of use for a long time.

- Air Filter: Reduces excessive wear and tear on the internal components of the air compressor by cleaning compressed air hence improving its efficiency.

- Regular Maintenance: The compressor and other related machines should be checked often and their maintenance carried out frequently to help gain the maximum life cycle for the equipment.

- Pressure Monitoring: All pressures within the system must be properly checked to avoid putting excessive pressure on the system or beyond its standard pressure limit.

- Proper Ventilation: It is recommended, that the compressor should be installed in some open area with enough ventilation in order to avoid overheating the machine, and therefore reducing the efficiency of the compressor.

- Manufacturing Plants: Serves as a reliable source of air supply to run pneumatic instruments and devices that facilitate production lines and automation systems.

- Construction Sites: Perfect for delivering airflow necessary in powering heavy-duty equipment to get more work done and reduce time on construction sites.

- Automotive Workshops: Supplies the required pressure of air in maintaining vehicles’ tools and equipment for better and more efficient running operations.

- Metal Fabrication: Enables cutting of metal, and drilling among other metal operations that need constant and strong airflow.

| Item | Technical Parameter | |

| Unit Model | JX-40APM2 | |

| Pressure(MPa) | 0.6/0.7/0.8/1.0/1.3 | |

| Pressure(psi) | 87/102/116/145/189 | |

| FAD(m³/min) | 6.8/6.4/5.9/3.9 | |

| FAD(CFM) | 240.1/226.0/208.3/137.7 | |

| Power(kW/hp) | 30/40 | |

| Dimension(mm) | 1400*1100*1450 | |

| Weight(Kg) | 800 | |

| Pipe Diameter | G1 1/2 | |

Media error: Format(s) not supported or source(s) not found

Download File: https://www.vibmac.com/wp-content/uploads/2024/09/new_JX_40APM2_video_01.mp4?_=1

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 3.5/2.9/2.7

-

Power(KW/HP): 15/20

-

Weigt(kg): 500

-

Pipe Diameter: G1

-

Dimension(mm): 1300*980*1220

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 4.3/4.1/3.5/2.7

-

Power(KW/HP): 22/30

-

Weigt(kg): 560

-

Pipe Diameter: G1

-

Dimension(mm): 1300*980*1220

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 10.7/10/9.5/8/6.8

-

Power(KW/HP): 45/60

-

Weigt(kg): 1300

-

Pipe Diameter: G2

-

Dimension(mm): 1500*1230*1550

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 13.8/13/12.5/9.5/8

-

Power(KW/HP): 55/75

-

Weigt(kg): 1700

-

Pipe Diameter: G2 1/2

-

Dimension(mm): 2100*1440*1650

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE