Why Choose an Oil-Free Screw Compressor: How to Make the Right Decision?

Let’s first look at industrial air compressors and in this case, an oil-free screw compressor with reference to the single-stage oil-free screw compressor with PM VSD (Permanent Magnet Variable Speed Drive) is recommended for many applications. , the types of compressors that are most popular for the creation of solar-powered systems are characterized by reliable power, high performance, and energy efficiency. These are used commonly in manufacturing industries, car industries, medical field, food processing industries and many others. Now let’s take a closer look at how you can get a big advantage of using oil free screw compressor.

What is an oil free screw compressor?

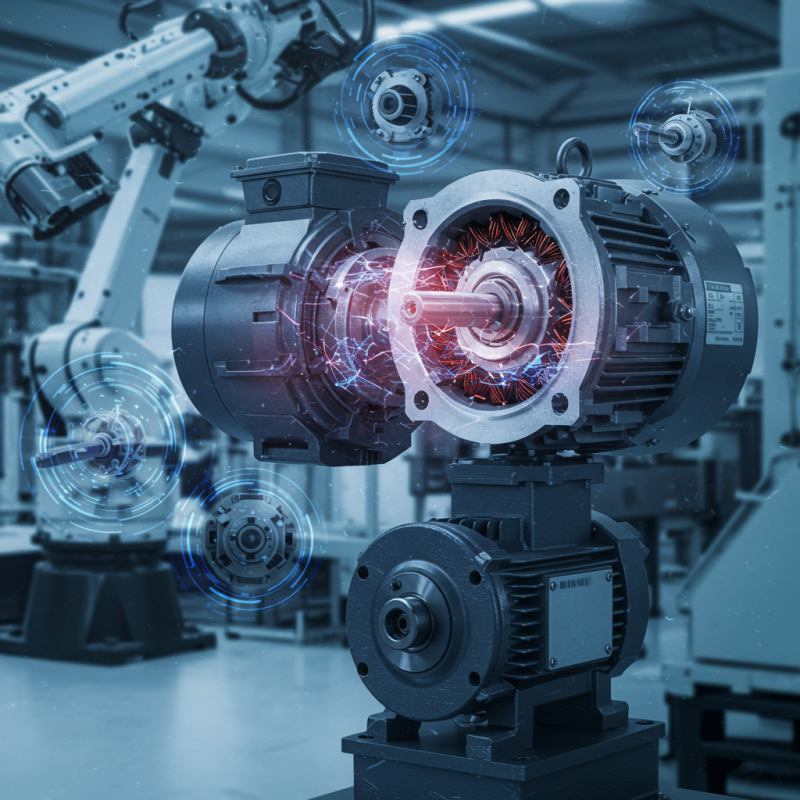

An oil-free screw compressor employs a screw system to compress air on the same system without using any lubrication oil in the compression process. This implies that in the application of the air by the compressor, it lacks the qualities of oil or moisture and thus well suitable for application that requires clean and dry air. The new oil-free compressors have an additional PM VSD technology that allows velocity control in compressor speed decreasing the energy consumption and, therefore, cutting the maintenance expenses.

What Benefits of Oil-Free Screw Compressors?

The Air, Pure and Free from Contaminations

The primary benefit of an oil-free screw compressor is that gives out clean, oil-contaminated air. In industries like food and beverage processing, pharmaceuticals, and manufacturing of medical equipment, this is desirable. Suspended solid in the air can compromise the quality of the products, the security of operation and efficiency of the machinery.

Energy Efficiency

The single-stage oil-free screw compressor, especially those from PM VSD ranges of the product line, provides energy-saving performance. Having a variable speed drive mechanism, the motor of the compressor will only need to operate at the level of air requirement rather than steady maximum level. This makes these compressors amongst the most energy efficient and cost effective on the market suitable for business looking to cut down on cost and emission.

Lower Maintenance Costs

These compressors have the advantage of containing fewer parts than those conventional screw compressors that use oil for operations. This leads to minimal usage of components and lowers incidents of constant usage and subsequent frequent servicing. In this case, spent machinery is more basic with increased durability and service intervals as compared to more complex designs of the multi-stage oil flooded screw compressors.

Longer Equipment Life

The use of a frequency conversion permanent magnet motor in the oil-free screw compressor reduces mechanical shock, allowing the gentle start. As must be expected, this means that the general usage does not worsen the state of the equipment as it would be otherwise placed under normal usage and thus, results in a longer duration before new replacement is required. Due to the lack of stress and strain conditions inherent in the normal operation of traditional compressors these units are extremely durable and offer reliable operation over longer periods.

Why it is important?

Low Noise Operation

The PM VSD oil-free screw compressor has one major benefit In the sense that it is quiet as compared to other similar products. The PM VSD compressor operates at a more constant frequency compared to conventional fixed speed type, while reducing mechanical noise level greatly. It therefore comes in handy where there is need to regulate the kind of noise been produced and thus ideal for use in some offices, hospitals and other similar places.

Compact and Portable Design

Single-stage screw compressors specifically are highly portable air tools with oil-less versions small in size. These compressors are compact in size and this relieves businesses which do not have enough space to accommodate large equipment. These characteristics also feature the versatility of the light guage steel frame buildings through easy transport, storing and installation for building purposes that may be movable or temporary. This extra freedom becoming an alternative owes its usefulness for business that requires mobile or changeable air compression plants.

High Safety Standards

Advanced control system in the modern Oil-Free Screw Compressor has an applications interface that can monitor different parameters like the temperature, pressure of exhaust gas, current fluctuations and frequency. It also maintains against those problems such as over heating, irregular pressure or current excessive, so the compressor can work properly. The safety features are for the protection not only of the compressor but of other equipment in the system, thus significantly minimizing periods of compressor shutdown due to failure.

Why the Oil-Free Screw Compressor is Your Best Choice?

Consistency and Reliability

Oil–less screw compressor delivers a steady supply of compressed air forge use in industries where compressed air is needed continually without pressure drops. An oil-free compressor is designed to perform optimally, and when it does, your operations are not interrupted, thus increasing production.

Environmentally Friendly

Due to absence of any kind of oil used in the compression process, these compressors are less hazardous to the environment as those that require oil for lubrication. As no oil is expelled into the environment, companies can achieve lower status of their environmental responsibility and fit the trend of sustainable business practices.

Cost-Effective Over Time

While oil-free screw compressors are suitably more expensive than the oil-lubricated ones, their costs are justified by the low cost of maintenance and their longer lifespan as well as energy efficiency. Despite these service costs being lower and energy efficiency being higher, these compressors are therefore highly cost effective in the long run.

Selection Criteria for Oil-Free Screw Compressor

Understand Your Air Demand

Before going to select an oil-free screw compressor, it is essential to assess the actual need and expectation for air. Things to ponder about include the pressure and flow rate that you consider necessary for your processes, how frequently you need compressed air and how long the compressed air will be used. If your requirements vary, a PM VSD compressor with variable speed drive is appropriate for the variation in air requirement.

Consider the Application

The nature of application that you are putting the compressor into will also determine your selection further. For industries that need air free from oil aerosols, oil, or moisture, food and pharmaceutical industries especially an oil-free screw compressor is mandatory. Although a more advanced model may be needed for heavy industry or construction work, simply to inflate a car tire, a simpler model will do.

Assess Energy Efficiency

In cost-saving initiatives, perhaps the most important thing that businesses seeking to cut their energy usage must own is an efficient compressor. First, look at the model that was equipped with PM VSD technology, which helps the motor adjust occasionally to the increased demand in energy usage. Another benefit will be that you will only be using power essential in operating it and hence cut out on expenses.

Check for Safety Features

Make sure that the particular compressor type you are going to use has built-in smart control option for the temperature and pressure checks and other significant indicators. Security measures are all crucial to reducing and minimizing operational risks and ensuring that the right safety precautions are taken in order to safeguard your machines and the majority of employees.

Assess Maintenance Requirements

Make sure to select a compressor that matches your capacity to maintain it. For further implications, in case you don’t want to employ frequent maintenance on the equipment, an oil-free screw compressor is ideal. These compressors involve little or no need for oils than the oil-lubricated types hence; there are lesser chances that they will need maintenance services, frequent overhauls and replacements.

Consider Size and Portability

When choosing a type of compressor, if the facility is small or for companies that need portability, the size of the compressor should be small. Due to their relatively small size, oil-free screw compressors are easy to store, transport and integrate enhancing their usability.

Conclusion

Oil-free screw compressor particularly those with PM VSD technology, offer numerous advantages, including clean air, energy efficiency, low maintenance costs, long service life, and low noise operation. It is an excellent choice for industries requiring high-quality, reliable compressed air. When choosing the right oil-free screw compressor, it’s essential to consider your specific air needs, application, energy efficiency, safety features, and maintenance requirements. By selecting the right compressor, you can enhance your business’s efficiency, reduce costs, and contribute to a more sustainable and environmentally-friendly operation.