Reliable Motors for Large Industrial Applications: Boost Efficiency and Performance

2025-02-28

Motors for Large Industrial Applications: Powering the Future of Heavy Industry

When it comes to powering heavy machinery and driving large-scale operations, motors for large industrial applications are crucial. Whether you’re managing a manufacturing plant, overseeing mining operations, or maintaining complex infrastructure systems, selecting the right industrial motor can make or break the efficiency, reliability, and longevity of your machinery. In this article, we will explore the various types of motors used in industrial applications, their technical features, and how to choose the best solution for your specific needs.

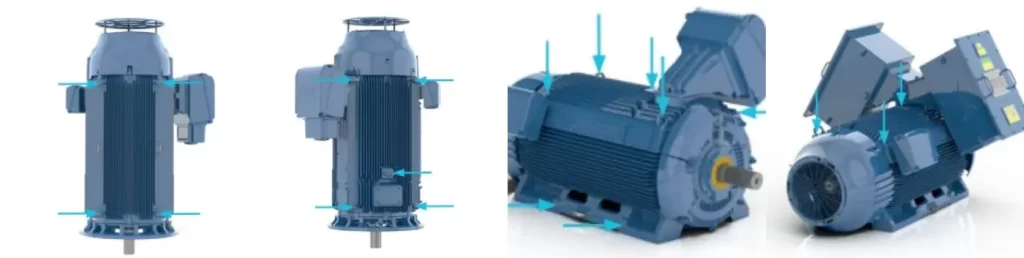

W51 HD Three-Phase WEG Motor: Powering Industrial Efficiency

The W51 HD Three-Phase WEG Motor is designed for heavy-duty industrial applications, offering unparalleled performance, energy efficiency, and durability. Whether you’re working in manufacturing, textiles, medical industries, or any other sector requiring reliable motors, the W51 HD stands out as a top choice. With advanced features and technologies, this motor is built to excel under demanding conditions.

Heavy-Duty Construction for Rugged Industrial Applications

One of the standout features of the W51 HD Three-Phase WEG Motor is its heavy-duty construction, making it perfect for industrial settings where equipment must endure high loads and extended operating hours. This motor’s design ensures it can handle the stress of high-demand applications like pumps, compressors, conveyors, and large industrial machinery. The robust build guarantees exceptional longevity, reducing the likelihood of costly repairs or replacements.

Key Benefits:

Built for tough environments and long operational cycles

Ensures operational reliability in high-load conditions

Minimizes the need for frequent maintenance

High Efficiency: Reducing Operational Costs

The W51 HD motor is engineered for high efficiency, providing substantial energy savings compared to traditional motors. Its design maximizes the conversion of electrical power into mechanical energy while minimizing wasted energy, leading to lower operational costs. This high efficiency is particularly beneficial for industries looking to reduce energy consumption and meet sustainability targets.

Energy Savings: The W51 HD motor can provide up to 20% energy savings, helping businesses reduce their carbon footprint and lower utility costs.

Efficiency Features:

Optimized design for energy conservation

Reduces energy waste, ensuring better power usage

Versatile Applications Across Industries

The W51 HD Three-Phase WEG Motor offers versatility, making it suitable for a variety of industrial applications. From textile machinery to medical equipment, this motor is engineered to provide stable and reliable power, even in the most challenging environments. Its ability to work effectively across different sectors speaks to its adaptability and robust performance.

Industries Served:

Industrial Manufacturing: Ideal for driving large machinery and equipment in factories.

Medical Industry: Powers reliable and precise equipment used in medical applications.

Textile Industry: Ensures smooth operation of textile machinery, contributing to increased productivity.

Advanced Cooling System for Optimal Performance

To maintain peak performance, the W51 HD motor features an advanced cooling system. This system is designed to maintain the motor at the optimal temperature, preventing overheating and ensuring that the motor performs efficiently. Overheating can cause damage to the motor, reducing its lifespan and increasing maintenance needs. The advanced cooling system addresses this issue, allowing the motor to run smoothly for extended periods without compromising efficiency.

Cooling Features:

Prevents overheating, improving motor longevity

Ensures the motor operates within the optimal temperature range

Enhances system efficiency by preventing energy losses due to heat buildup

Compact, Yet Powerful: Perfect for Tight Spaces

Despite its heavy-duty construction, the W51 HD motor is compact and robust, offering high power density in a smaller footprint. This makes it ideal for environments with limited space where larger motors may not fit. Its small size, coupled with its powerful performance, means it can be easily integrated into various machinery without sacrificing efficiency or power.

Key Advantages:

Small dimensions for space-saving installation

Delivers robust performance despite its compact design

Ideal for tight spaces without compromising on power or efficiency

Low Maintenance and High Reliability

A crucial feature of the W51 HD motor is its low-maintenance design, which reduces the need for constant upkeep and minimizes downtime. The motor’s durability and reliable performance mean fewer repairs and longer intervals between service needs. This is especially valuable for industries that rely on continuous operation, where minimizing downtime is critical.

Maintenance Features:

Minimal upkeep required, reducing service costs

Reliable performance with fewer interruptions

Common Applications of Motors in Industrial Environments

Motors are integral to a wide range of industrial applications. Here are some of the industries and uses where industrial motors play a key role:

1. Manufacturing and Automation

In manufacturing plant automation, motors are used to power everything from robotic arms to conveyor systems. These motors ensure that the production line operates smoothly, efficiently, and with minimal downtime.

Types of Motors Used: AC motors, servo motors, gear motors.

Key Benefits: Efficiency, precision, and reliability.

2.Mining and Resource Extraction

In the mining industry, motors power large equipment such as crushers, mills, and conveyors. The motors used in mining applications must be able to withstand harsh environments and heavy loads.

Key Benefits: Durability, high power output, and safety.

3.Oil and Gas

In the oil and gas industry, explosion-proof motors are used to ensure safe operations in hazardous environments. These motors are designed to withstand the harsh conditions of oil rigs and refineries, where safety and reliability are paramount.

Types of Motors Used: Explosion-proof motors, high-voltage motors.

Key Benefits: Safety, reliability, and high power output.

4. Power Generation

Motors are essential in power generation plants, where they drive turbines, generators, and other critical equipment. Medium-voltage motors are often used in power generation due to their ability to handle large amounts of electrical power efficiently.

Key Benefits: Constant speed, high efficiency, and reliability.

Water Treatment and Chemical Processing

Motors in water treatment plants and chemical processing facilities must be capable of withstanding corrosive environments while maintaining high levels of performance. Corrosion-resistant motors and high-efficiency motors are typically used in these applications.

Key Benefits: Durability, efficiency, and performance in harsh conditions.

Motor Selection: How to Choose the Right Motor for Your Application

Selecting the right motor for your industrial application involves understanding the technical requirements of your operation. Here are some key considerations to keep in mind:

1. Power Requirements

The motor’s power must match the demands of your application. Whether you’re using motors for heavy-duty material handling or high-speed manufacturing, the motor must be able to provide the necessary power and torque without strain.

2. Efficiency

To maximize return on investment, choose energy-efficient motors. The cost savings from lower energy consumption can offset the initial investment in high-efficiency motors over time.

3. Environmental Conditions

If your motors will operate in extreme conditions (such as high humidity, corrosive environments, or explosive atmospheres), it’s critical to select motors that are suitable for these environments, such as explosion-proof motors or IP-rated motors.

4. Maintenance and Durability

Opt for motors that are known for their durability and low maintenance needs, especially if your machinery operates continuously. Induction motors and AC motors are often the go-to for applications that require long-lasting, low-maintenance solutions.

Conclusion: Choosing the Right Industrial Motor for Your Needs

Motors for large industrial applications are integral to the smooth operation of various sectors, from manufacturing and mining to power generation and water treatment. The key to optimizing your operations lies in selecting the right motor for your specific needs—whether that’s a high-efficiency industrial motor for energy savings, a servo motor for precision control, or an explosion-proof motor for hazardous environments. By understanding the technical specifications, applications, and performance characteristics of industrial motors, you can ensure that your machinery runs efficiently, reliably, and safely.

For more information on industrial motors and how to choose the right one for your operations, visit Vibmac Industrial Motors.