Energy-saving Air Compressor: The Smart Choice for Sustainable Manufacturing

2024-12-30

Why Energy Combining Air Compressors for Laser Cutting Tools?

Consequently, productivity, expense control, and sustainability have become some of the driving issues in the modern manufacturing environment. This system enables the user to use an economic and efficient air compressor that not only runs the laser cutting machine but also plays a major part in making the operations as continuous and efficient as possible. Energy-saving Air Compressor from Vibrant is designed to save energy and conveniently, making it possible for today’s industries and other applications to make waves.

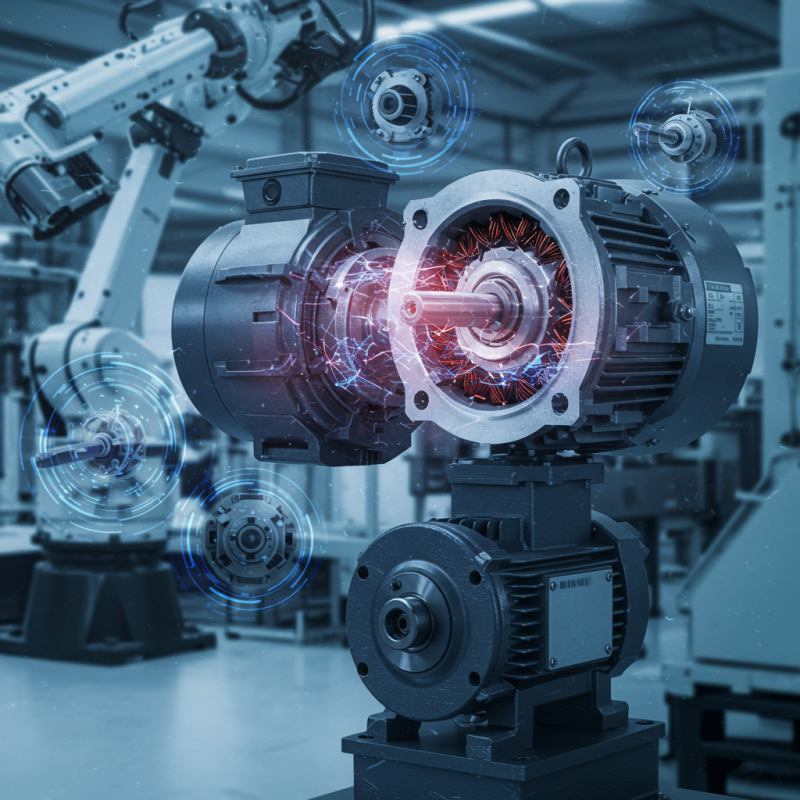

The Importance of Energy-saving Air Compressors for Laser Cutting

Laser cutting machines depend more so on regular and constant supply of air to enable them to perform their cutting services more accurately. Pneumatic equipment in these systems requires compressed gas that is steady, a prescribed pressure, and cleans air. High efficiency air screw compressors optimized for laser cutting machines play a major role on energy intake, utilization and the performance of the laser cutting machine. Air compressors of Vibrant are quite attractive due to the saving aspect that we offer together with optimizing the known laser cutting machines. This is realized via the use of advanced technologies, dependable components and efficient energy management systems. Here’s why these compressors are a valuable component in your laser cutting process.

Energy Efficiency: Reduced Power Consumption

An advantage rooted in the new-design energy-saving type of air compressor is that it conserves power. The conventional compressor designs suffer from high-start up current, creating instances of energy surge that is very expensive and ineffective. This problem is tackled by screw air compressors for laser cutting machines used by Vibrant which do not experience fluctuating power surges that are intelligent in design. Here, the motor regulation is in a way that its contribution to the power system is limited during the start-up and thus, little energy is wasted during this course.

Also, these energy-saving compressors used in normal operation perform essentially at optimum efficiency, hence user consume least energy in performing your laser cutting jobs affordably but effectively. But at the same time, the energy efficient usage does mean less amounts spent on electricity bills and is good for the environment.

A Stable Gas Flow and Pressure for Accurate Cuts

Fluency in the flow and pressure of the gas required for cutting has to be maintained accurately in order to achieve high quality laser cutting. Changes in pressure can be counterproductive to the quality of the cuts, which would mean wastage of material and time. Another part of air compressors for laser cutting machines is a highly developed control mechanism, which adapts gas pressure and gas flow constantly. It is important in laser cutting to maintain constant pressure, and this guarantee is provided by the Toyota Production System.

Both 16Bar and 20Bar pressures are available, with the compressor control system providing simple operation through an operation panel to ensure pin-point accurate cutting across the board. Equal air pressure means more precision when cutting, less mistakes, and, subsequently, higher quality work.

Cost Savings through Reduced Maintenance

As in any industrial processes, time and availability of capital for equipment repair causes a major expense. Older methods involve the use of conventional wear-out compressors which may demand huge maintenance costs. Screw air compressor from Vibrant is characterized by low maintenance. Some of these aspects include the thickened corrosion resistant steel pipes which improve not only the life time of the compressor but also removes the vibration and general wear and tear of the pipes. Compressors’ high level of construction and high anti-corrosive measure make its maintenance interval longer so its long run maintenance cost is low. Further, the chance of the compressors’ failure is low due to the use of the reliable PM motors, and hence your equipment will run for a longer duration without giving you operational hassles.

Super Low Noise and Vibration during Operation

Computation and sound are two critical issues in industrial areas, especially when running equipment like air compressors. Noise and vibrational levels which are too high interfere with work conditions, comfort and even safety of people and property in a building. Vibrant laser cutting machine air compressor has been designed to have ultra-low noise and low vibration when in use.

This design not only improves the environment for work for the employees but also produces a much better and efficient working environment. Less noise also conforms to the laws in areas where acoustics bears a significant degree of importance as well as minimizing on ear injury to workers.

High Performance and Clear Air Quality

The air compressor used in a laser cutting machine needs to provide optimal output. To ensure the stability and efficiency of the laser cutting machine. The screw air compressors used in Vibrant’s laser cutting machines are combined with unique oil control accessories and efficient post-processing components. The quality of available air can be significantly improved. Provides clean, dry and oil-free air to eliminate contaminants that interfere with the laser cutting process. Because they will cause deformation of the laser cutting machine or affect the cutting quality. Furthermore, these compressors not only increase the efficiency of the equipment due to the increased purity of the supplied air. It also extends the working time of key components.

High Performance and Clean Air Quality

Vibrant also brings to the market air compressors that come with custom control panels and inverters. These control panels and inverters were developed in-house to suit laser cutting lines. The intelligent control system through gas pressure and flow allows the operator to vary the pressure and flow to achieve the best output for the machine. This also means, depending on the strength level of the application or the type of material used. These compressors can be easily adjusted to increase overall versatility and efficiency.

Why Vibrant Compressor?

One major specialization that has propelled Vibrant to relish a strategic niche is supplying state of the art energy saving air compressors for laser cutting equipment. Here’s why you should choose us:

• Energy Efficiency: Choose from a range of Yuken products. You can be sure you’re choosing an energy-efficient compressor that will lower your bills and reduce your impact on the environment.

• Custom Solutions: That’s why we develop control systems that fit your operating style. To help you achieve optimal results and convenience.

• Durability and Reliability: Our compressors are made of high-quality anti-corrosion, anti-vibration and wear-resistant materials. This extends the compressor’s service life and reduces maintenance requirements.

• High Performance: Its many accessories offer superior oil control capabilities. Some post-processing aspects include high-quality clean air to achieve optimal laser cutting results.

• Reduced Noise and Vibration: Increased work safety and comfort of your employees are guaranteed thanks to the low noise level of our compressors.

• Cost-effective Operations: Due to low maintenance and energy-saving characteristics, our compressors have a small long-term cost of operation.

Conclusion

Choosing an energy-saving air compressor for your laser cutting machine is a smart investment in the future of your business. Vibrant air compressors provide superior efficiency, stable performance, and reliable cost-saving benefits. With features like low maintenance, energy efficiency, and high performance, our compressors ensure that your laser cutting operations run smoothly, accurately, and at a lower cost. Contact us today to learn more about how our energy-saving compressors can benefit your business.