Top DC Motor Industrial Applications: Enhancing Efficiency Across Industries

2025-03-04

DC Motor Industrial Applications: A Deep Dive into Their Vital Role in Automation

Introduction

DC motors are at the heart of countless industrial applications, playing a pivotal role in the success of various systems. From manufacturing plants to robotics, these motors are essential in driving precision, efficiency, and reliability. As industries continue to embrace automation, understanding the diverse applications of DC motors in industrial settings becomes increasingly important. In this article, we will explore the key DC motor industrial applications, dive into specific sectors utilizing these motors, and examine their technical aspects, ensuring that your understanding of these motors’ power and functionality grows.

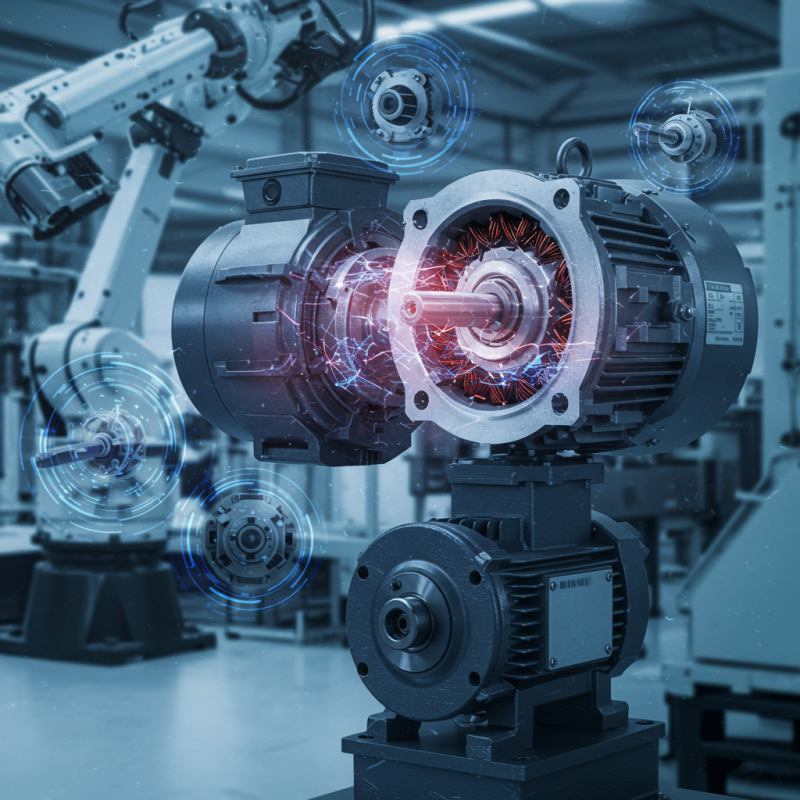

What is a DC Motor?

A DC motor (Direct Current motor) is an electromechanical device that converts electrical energy into mechanical energy via the interaction of magnetic fields. The motor’s speed and torque can be controlled effectively, making it a preferred choice in industries that require high performance, precision, and control.

Industrial Applications of DC Motors

DC motors are integral to various industrial applications, offering solutions in automation, material handling, and process control. Let’s break down how these motors power the industries:

1. DC Motors in Industrial Automation

Industrial automation is one of the most significant sectors benefiting from DC motors. These motors are used to automate manufacturing lines, ensuring precision and reducing human error. Whether it’s controlling the speed of conveyors or integrating into robotic arms for complex operations, DC motors make automated systems more efficient.

Example Applications:

- DC Motor for Conveyor Systems: These motors drive the conveyor belts, ensuring that materials are transported smoothly and efficiently in a factory.

- DC Motor for Robotics: The growing field of robotics relies on servo and BLDC motors for precise movements, making them crucial for automation.

2. DC Motors in Manufacturing and Processing

From textile machinery to printing presses, DC motors are indispensable in various manufacturing processes. These motors drive the machinery that produces everything from textiles to packaging materials, ensuring that the production line operates with minimal disruption.

Example Applications:

- DC Motor for Textile Machinery: Drives the mechanisms in spinning, weaving, and finishing processes.

- DC Motor for Printing Presses: Controls the paper feed and speed regulation during printing operations.

3. DC Motors in Material Handling

In warehouse logistics, material handling systems require motors that can perform under demanding conditions. DC motors for material handling applications, such as hoists, winches, and cranes, ensure that goods are moved efficiently and safely.

Example Applications:

- DC Motor for Winches: Used in heavy-duty equipment for lifting and pulling.

- DC Motor for Material Handling: Powers systems that move goods within warehouses or factories.

4. DC Motors in HVAC Systems

DC motors are also widely used in the HVAC (heating, ventilation, and air conditioning) industry. These motors power fans and pumps, ensuring optimal airflow and cooling in large industrial facilities.

Example Applications:

- DC Motor for Fans: Drives ventilation fans to regulate temperature and airflow in industrial settings.

- DC Motor for Pumps: Controls the flow of liquids in systems such as water treatment plants and oil rigs.

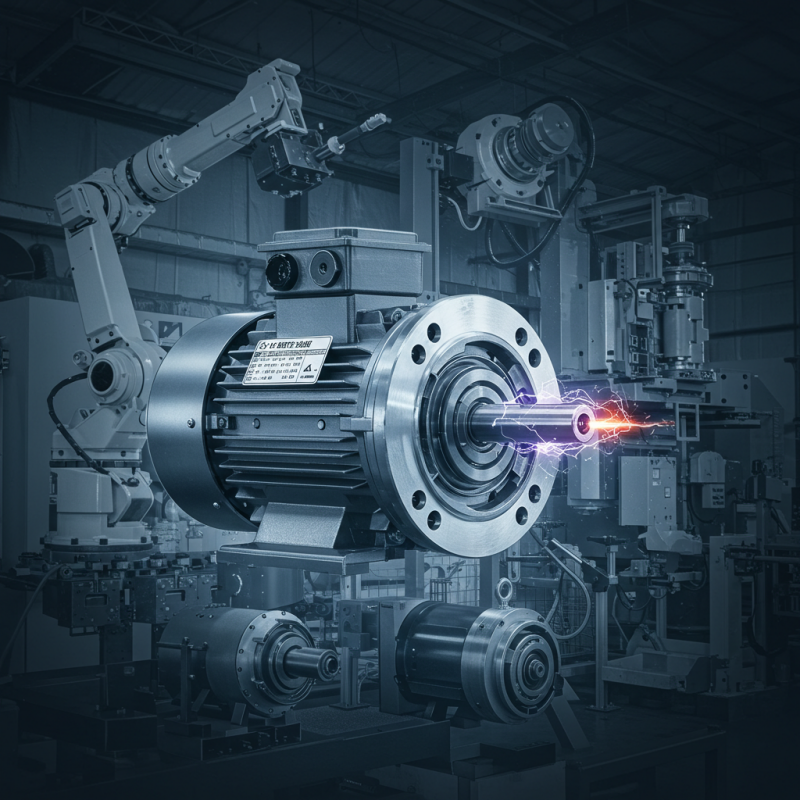

5. DC Motors for Machine Tools

Machine tools require motors that can provide precise control over speed and torque. DC motors for machine tools allow manufacturers to achieve intricate details and high-performance outputs in applications such as CNC machines and lathes.

Example Applications:

- DC Motor for CNC Machines: Powers cutting tools and helps maintain accurate movements in precision engineering.

Technical Specifications of DC Motors

Understanding the technical aspects of DC motors is key to selecting the right motor for industrial applications. Here are some crucial parameters to consider when evaluating a DC motor:

- Torque: The rotational force generated by the motor. High torque DC motors are used in applications requiring strong mechanical movement, such as winches and conveyors.

- Speed Control: The ability to vary the motor’s speed is essential for variable speed applications like pumps and fans.

- Efficiency: DC motors, particularly brushless DC motors (BLDC), offer high efficiency with lower maintenance, making them ideal for long-term industrial applications.

- Power Rating: Motors are available in various power ratings depending on the load they need to drive. The power rating of the DC motor for robotics or DC motor for manufacturing will depend on the application’s requirements.

Motor Control Technologies

Motor control is another critical aspect of industrial motor applications. Variable frequency drives (VFDs) are commonly used with DC motors to control speed and direction in many motion control applications. Advanced control systems like programmable logic controllers (PLCs) also allow for automation of motor-based systems, enabling higher precision and flexibility in complex systems.

Maintenance and Efficiency Considerations

Maintaining DC motors is essential to ensure long-lasting performance. Regular checks of motor efficiency, brushing systems in brushed motors, and bearing lubrication in DC gear motors can help avoid unexpected downtimes. DC motor maintenance is essential for industries relying on these systems to avoid costly breakdowns.

Benefits of Using DC Motors in Industrial Applications

1. Precision and Control

DC motors offer superior precision when it comes to motion control. This makes them ideal for applications like robotics, CNC machinery, and even automated packaging lines where high-accuracy movements are critical.

2. Energy Efficiency

Energy efficiency is a key concern for industries aiming to reduce operational costs. DC motors, especially BLDC motors, are designed to use less power while still delivering high performance. This makes them more sustainable for long-term use in industrial automation.

3. Cost-Effectiveness

While some types of DC motors may come with a higher upfront cost, their low maintenance and long operational life make them cost-effective in the long run.

4. Versatility

DC motors are highly versatile, capable of handling a wide range of industrial motor applications. Whether it’s in manufacturing, HVAC systems, or robotics, DC motors can be tailored to fit a variety of functions, from low-speed drives to high-torque operations.

Conclusion

DC motors are foundational components of industrial automation, ensuring efficiency, precision, and reliability across various sectors. Whether you’re in the textile industry, material handling, or robotics, DC motors are an integral part of modern industrial systems. By understanding their technical specifications and applications, you can harness their full potential to optimize your industrial operations.

For more information on industrial DC motors, visit our website.