Why VIBRANT Air Compressor Parts Are Ideal for Laser Cutting Machines?

When selecting air compressors for laser-cutting machines, the most important criteria that should be considered are stability and productivity. Specifically, the air compressors of VIBRANT are for producing a continuous flow of air that would help you maintain a steady cutting line in laser cutting. Given the nature of Air Compressor Parts applications, there is no better way than to incorporate our technologies and several additional customizations in order to have VIBRANT.

Importance of Choosing the Right Air Compressor for Laser Cutting

Laser cutting machines require compressed air which is why the quality of air compressed is a critical aspect of the process. It must be clean air for the purposes of cutting and hence has to be supplied at a constant pressure that will give a high level of accuracy. What is more, the air compressor flow has to be steady, the air should be clean with the appropriate pressure, and the machine has to be well protected from failure. It is critical to select the right air compressor when using this equipment because it will directly impact the functionality and productivity of the laser cutting.

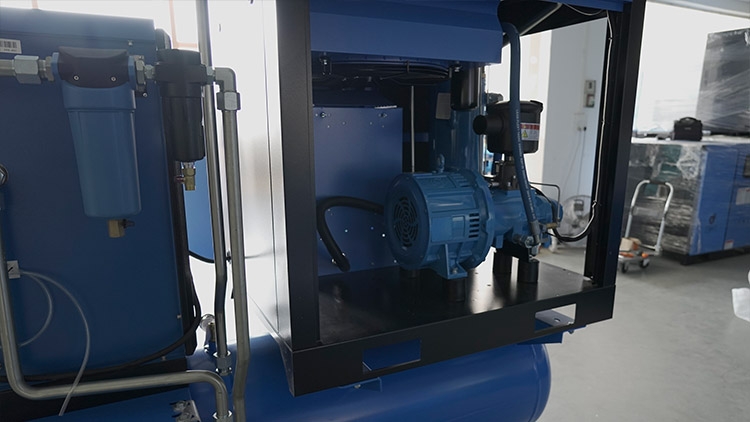

The VIBRANT air compressor has been designed for Laser cutting machines to fit its diverse needs, coupled with air filtration for clean dry air. This means that the air supply of the laser cutting process is stable and always available to power the cutter to the highest expectations.

Why VIBRANT Air Compressors Are the Ideal Solution?

Stable and Reliable Performance

VIBRANT air compressors have been designed to deliver stability and reliability of the airflow which is very important in laser cutting. It is equipped with a low failure rate permanent magnet (PM) motor, which prevents variation of cutting output power and checks in cutting processes. The intelligent control system thus measures the changes in pressure and gas flow rates in real-time and enables optimum cutting operation of the compressor for the laser operating conditions required for laser cutting.

Customizable Control Options

VIBRANT provides optimal Control panels and inverters for each of the air compressors depending on the laser-cutting machinery. Managing pressure is enabled from the operating console that ranges from 16Bar to 20Bar and highly developed control systems. This makes the air pressure to be held within the most opportune levels for the laser cutting technique to work at its required capacity.

Quiet and Low-Vibration Operation

Laser-cutting machines, among others, are sensitive and require noise and vibrations to be kept to the bare minimum. The VIBRANT air compressors are very low-noise and ultra-vibration-friendly devices intended to minimize noise level vibrations. These forms of vibrations are likely to cause more destruction and would result in increased costs that are related to the repairs of the machine and other related products that are used while at the same time enhancing the durability of the machine and the other related products that are used.

Energy Efficiency

Energy conservation is one of the main factors with regard to the selection of the air compressor. Traditional air compressors are high in power surge when starting and the power finally stabilizes at the output when it is most needed. The VIBRANT air compressor comes with smart start technology that does not allow energy wastage in the initial stage of the unit and hence will be more efficient than the standard air compressors.

The Importance of Choosing the Right Air Compressor for Laser Cutting Machines

Low Maintenance and Long Operational Lifespan

The air compressors being produced are as follows; VIBRANT air compressors are made to be of the highest standard of durability. The compressors are made out of corrosion-resistant steel pipes, thus eliminating the need for them to be replaced or maintained very often, hence lowering the overall cost of running the compressors.

High-Performance Air Quality

This is due to the fact that compressed air used in cutting laser machines must be free from contaminants which may cause hitches in the machines and reduce the accuracy of cutting required by the customer. The VIBRANT air compressors have the best air filters where there is the use of the three-stage filter to enhance the production of clean air only.

Customizable Solutions for Your Specific Needs

At VIBRANT, it is noted that each of the industrial applications may have different requirements. That is why our air compressor production can be customized to suit your business needs. In case one needs a precise power, pressure, exhaust volume, or motor set, the engineer will make a unit for your requirement. We also have flexible cooling options and therefore make sure that the compressor offers its best performance irrespective of the prevailing working conditions.

How to Choose the Right Air Compressor for Your Laser Cutting Machine?

Selecting the right air compressor for the laser cutter is one of the biggest decisions that every buyer is to make after evaluating certain factors. The following are some of the points of consideration:

Airflow and Pressure Requirements

It is also important to figure out the amount of airflow and pressure that is necessary for the laser-cutting machine. With the VIBRANT air compressor offering operating pressure ranging from 16Bar to 20Bar, this gives a user variability in range to suit different operations involved in the cutting process.

Filtration and Air Quality

Laser cutting involves the use of nitrogen hence there is a need to have a constant inflow of dry air. That is why VIBRANT’s three-stage filtration system allows the creation of a clean-air environment ideal for laser cutting and other activities requiring purity.

Energy Efficiency

Choose an air compressor model that constantly consumes the least energy but at the same time meets the required performance capability. VIBRANT compressors have energy control parameters such as slide start-up with low rush current hence using less power throughout the process.

Durability and Maintenance Costs

It is recommended to look for a compressor that owes long-term service and is not prone to many breakdowns often requiring servicing. Since VIBRANT is built with corrosion-resistant materials and the equipment has a low-maintenance design, the operating cost in the long run is rather low and simply speaking, it has a high ROI.

Customization Options

There are various types which may include features like the type of control panel, cooling type, and the amount of power that the compressor must have. With VIBRANT’s series, it is possible to choose the most suitable solution based on the model of the laser cutting machine.

Why Choose VIBRANT Air Compressors?

The author aims to provide VIBRANT and portable air compressors for sale and hire that are of good quality with high efficiency and reliability suitable for industrial sectors all over the world. The applications of VIBRANT air compressors are very broad, so they range from the enhanced manufacturing of various products to the manufacture of automobiles, aircraft, and so on.

Strong Pre-Sales and After-Sales Support:

Our company has a customer support team who will be always available to answer all your questions as well as offer technical support whenever you have issues with your air compressor hence giving you a guarantee of continuous performance. Our company also provides comprehensive warranties and services in the field of emergency.

Quality and Certification:

VIBRANT air compressors are produced with high-quality standards to meet market standards and they have ISO, UL, CE, EMC, TUV, and SAA approvals. It also means that the customers get the necessary quality assurance that our products are of high quality and that they work effectively in their respective markets.

Competitive Pricing:

It has a conceptional supply chain and manufacturing process to provide competitive prices for VIBRANT air compressors while at the same time using quality materials, making it economical to use in laser cutting services.

Conclusion:

Choosing the right air compressor for your laser-cutting machine is crucial for maintaining performance, reducing operational costs, and increasing the longevity of your equipment. VIBRANT air compressors offer unparalleled efficiency, reliability, and customizability, making them the ideal solution for laser cutting applications. Our advanced technology and commitment to quality ensure that you get the best product for your business. Contact us today to learn more about how our air compressors can improve your operations.