Two Stage Screw Air Compressor

-

Custom Controls: Raw control panels and inverters designed and developed in the plant

-

Stable and reliable: PM motor has a low failure rate and stable output power.

-

Quiet Operation: Super low noise and vibration during operation

-

Easy maintenance: Long maintenance cycle and low running cost.

Twin-screw two-stage compression technology, the use of horizontal two-stage structure, compression efficiency is higher, two-stage compression between the host of the existence of a coolers so that the machine has a better ability to apply the ambient temperature, two-stage compression is more energy efficient, compared to ordinary single-stage can save energy by 15% or even more.

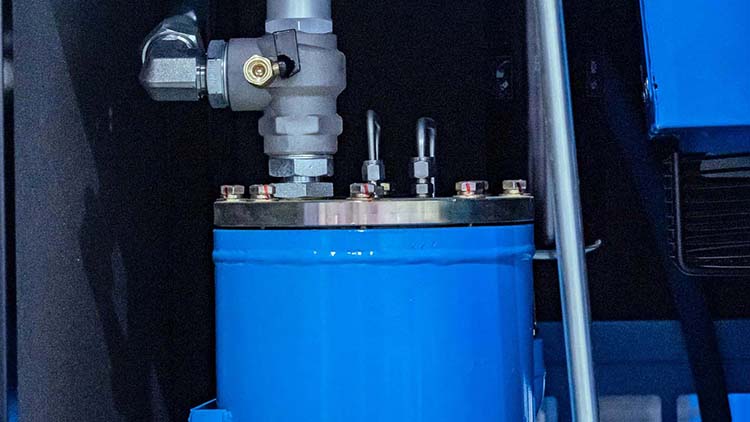

Intelligent control of high pressure panel, accurate control of gas pressure, double screw design compression efficiency, the use of rare metals to create a rotor, wear-resistant and high temperature, parts specially designed for high-pressure gas service to ensure safety.

Adopting high quality control panel, adapting a variety of frequency converter, accepting parts selection, the control system accurately controls the temperature, air output, exhaust pressure, etc. of the air compressor operation, to ensure the smooth operation of the machine and to meet the demand.