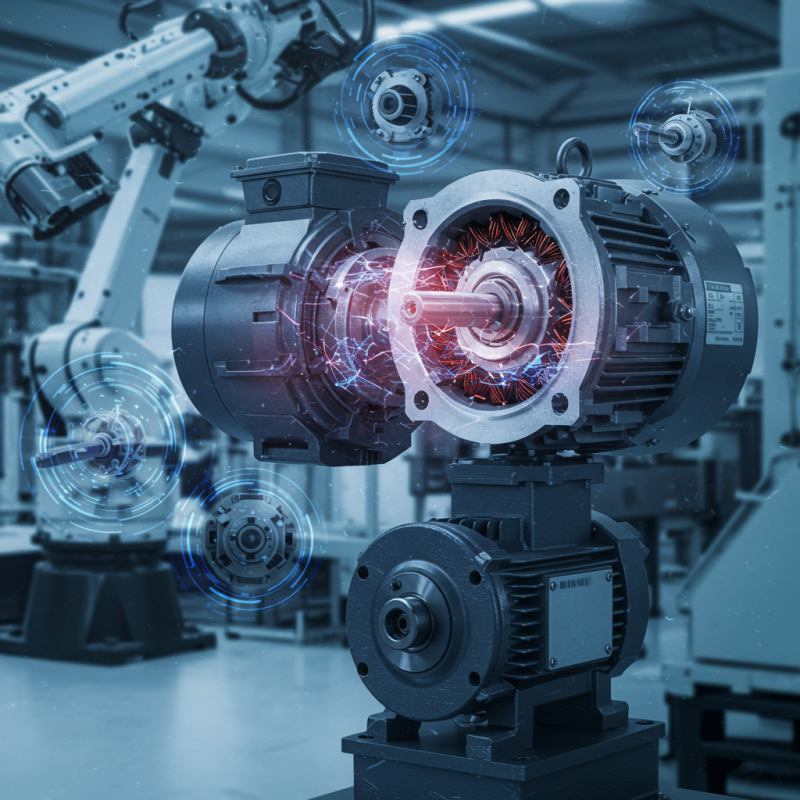

High Voltage Induction WEG Motor: Reliable Power Solutions for Industrial Applications

2024-12-28

Why Do Industrial Processes Require High-Voltage Induction Motors?

One of the industries most vital and relied on themes Global High-voltage induction motors such as the HGF Line Medium-High Voltage Induction WEG Motor. Such motors are durable to be used at industries to support continual production no matter the prevailing difficult conditions. In mining, oil and natural gas, power generation high volt inductions motors are crucial elements of products that contribute to firms sustainable business.

The Importance of High-Voltage Induction Motors

The Three-phase Induction Motor from HGF is extremely essential in industries where reliable power supplies are required. These motors are designed for versatility, for situations where standardized low-voltage motors would not perform well or could not be used at all. These motors work at voltages of between 2,300V and 6,600V; high voltage is required in order to produce high power, which is needed in an industrial environment to power large mechanical equipment.

Powerful and Efficient: These motors are designed with high output power of between 355 kW-2800 kW depending on the need of the facility. What this all means is that industries will be able to depend on high voltage motors to continuously drive machinery, reducing the costs of having to shut down for service.

Reliable in Harsh Environments: Companies that operate in the mining, oil and power plant industries for instance experience unforgiving operating conditions. High-voltage indication motors are built to sustain these circumstances attributing from their robust structure and efficient cooling mechanisms. It helps avoid emergencies so that equipment can run for more days and hours without suffering from breakdowns.

Energy Efficiency: Superior product types such as the WEG HGF Line produce energy amounts higher than the desired levels, therefore lowering energy consumption. This is especially important for industries that are in the process of trying to minimize their operating expenses and the effect they have on the environment.

Advantages of Induction Motor and High Voltage Induction Motors

High voltage induction motors come with a number of advantages which if adopted can improve the production, effectiveness and dependability of power processes.

Reduced Operating Costs

Efficient motors enable low energy utilization in motor applications. Because these motors function at better efficiency levels, they consume less power thereby incurring less operational costs and using less energy.

Durability and Longevity

High voltage induction motors are designed to be strong hence efficient in their performance for longer periods. These motors are assembled with quality parts such as cast iron housing, such motors do not breakdown and can operate under harsh environment for long times.

Versatility

Available for multiple applications and with a large power range, high-voltage induction motors from WEG are the perfect combination of efficiency, reliability and robustness. In all industries, from mining through to power generation and manufacturing, the range of power output and operational characteristics enables industries to select the appropriate motor.

Low Maintenance

Such motors have been designed to be low maintenance requiring less frequent repairs or replacement of their components. Cooling systems and protective measures are well arranged so such motors remain in good condition for an extended period of time, and basic inspections only are needed for them to run efficiently.

How to Choose the Right High-Voltage Induction Motor?

Selecting the best high-voltage induction motor is very important in terms of productivity and cost in industries. Here are key factors to consider when selecting a motor:

Power Output Requirements

This power output should correspond to the working parameters of your equipment or the system you have. This makes WEG possible to supply a range of power outputs ranging from 355 kW to 2800 kW that are able to support any industry.

Cooling System

Take into account the environmental pressure of your industry. Using motors in various applications that require air or water cooling facilitates adequate cooling during intensive procedures hence reducing overheating of the motors and improving on their lifetimes.

Motor Construction

Motor material is one of the most sensitive aspects of designing to consider when it comes to durability and avoidance of wear. WEG’s high voltage motors having material FC-200, cast iron the motors are designed for operation in severe areas that provide reliable performance of industries.

Environmental Considerations

Determine if the motor’s IP rating is suitable to serve in the environment in which the motor is going to work. Motors with an IP55 rating are best suited for application where the environment may be exposed to dust and water.

5. Maintenance and Serviceability is defined as the ability of an object to be maintained during its life cycle and to be rendered suitable for use in the context intended.

Why Choosing Us to Supply You High-Voltage Induction Motor?

When choosing a high voltage induction motor that shall be used for industrial application the user should ensure that the supplier he is dealing with has a reputation for delivering quality, efficiency, and reliable motors. Here’s why you should choose us:

Expertise and Reliability

Having worked for many years in the field of providing electrical equipment, we supply solutions of the highest quality, such as high-voltage induction motors to satisfy the highest performance requirement. Our team of specialists will help you to choose the most suitable motor for your application.

Comprehensive Product Range

Below is our list of high voltage induction motors that come in different types to suit various industries. We have a motor for mining processes, for power generation applications, and for production processes we have a motor that improves throughput and output.

Customization Options

This is the reason why we know that every application that contains industry is different. This series of high-voltage motors have optional functions for pole structure design and cooling system design according to its applications.

Better Hardness and Strength

Our motors come from the best sourced materials and equipment and have to pass a daunting test on their sturdiness and efficiency before being released to the market. Long-term performance is important to us and thus we ensure that your business does not have a lot of unnecessary downtimes.

Customer-Centric Service

In every step of our business, from selection, purchasing, installation, and maintenance, our customer service is superb. We value your time, and after working with you to have your preferred motor installed, our team is ready to guide you on how to have it produce optimum results for the set duration of its use.

Conclusion

High-voltage induction motors like the WEG HGF Line are essential for industries that require robust and reliable power sources for their heavy-duty operations. With superior efficiency, durable construction, and versatile cooling options, these motors provide significant benefits, including reduced operating costs, increased productivity, and minimal maintenance requirements. By choosing the right motor for your application, you can ensure efficient and long-lasting performance. At VIBRANT, we offer high-quality, customizable high-voltage induction motors designed to meet the specific needs of your industry. Let us help you power your operations for greater success.