Why Industry Needs Fixed Speed Air Compressors?

Pressure switch applications can be found in various industries where there is a necessity to have a stable and continually working source of compressed air driving the functioning of tools and production lines. Fixed-speed air compressors do just that, which is to deliver air at a constant speed thus being very reliable. These are fixed compressors that are meant to guarantee constant air delivery thereby improving organizational performance. Interestingly, Air Compressor for Industry aren’t a luxury that many businesses can afford to do without using and this is why we will be expounding on why fixed speed air compressors are important and how to choose the right one for your company.

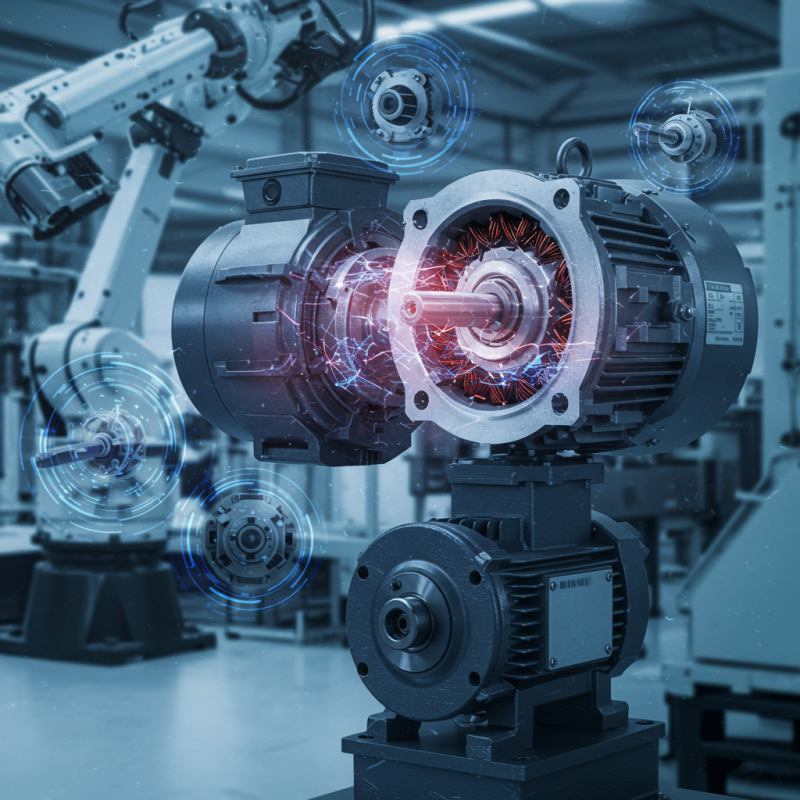

What is a Fixed Speed Air Compressor?

A fixed speed air compressor works at a fixed speed, thereby providing a purged and consistent supply of air to several systems that require it. While variable speed compressors have the ability to modulate their speed to match the required levels, fixed speed models work at optimum speed all the time irrespective of the level of output being required. It is necessary for many industrial applications because it provides the required constant air flow, accuracy, and durability.

Why are fixed-speed air compressors important to the industry?

Intermittent and Steady Supply of Air

Since constant air pressure is important in industries where compressors are required for the continuous operation of machines, fixed speed air compressor provides a constant flow of air pressure required for the operations of machines. They also keep varying the rates of airflow which result in over or under-pressurization, a situation that is disastrous to equipment and unsuitable for productivity. It is particularly advantageous in processes that need an uninterrupted and intermittent supply of air.

Energy Efficiency

Airborne fixed speed air compressors are designed to maintain optimum energy efficiency. Even though they operate at a constant speed, modern models such as the VIBRANT Fixed Speed Air Compressor are friendly to the power utility with low power consumption. These motors offer high performance at relatively low power consumption and can be well suited for industries that undertake large energy expenses in their production processes.

Low maintenance and durability

Stationary air compressors work at a certain speed and are manufactured to meet the needs of industrial applications. These are the parts that make up this type of compressor and note that these components are made from quality materials, and thus these compressor models need the least maintenance, and they are resistant to wear out. Their designs are strong enough to make them run for long periods, thus minimizing times of downtime and related repair expenses.

Stability and Performance

Due to advanced intelligent control systems fixed speed compressors such as VIBRANT guarantee exhaust pressure for instance at VIBRANT model. This ensures that the air pressure is well maintained all through the operation for high-performance applications. These compressors offer a high level of accuracy which increases production and eliminates cases where pressure might have dropped.

How to Select the Right Fixed-Speed Air Compressor for Your Industry?

When choosing a fixed Air Compressor for Industry for your business, then there are some issues that have to be considered to meet the needs.

Power Requirements

Knowing the flow rate of compressed air is essential; therefore, you’ll need to identify the requirements of your facility. This depends on the number of machines you have and the internal air requirements that each of the stated machines demands. A compressor with enhanced ability is best fitting for businesses with high requirements; however, a huge compressor is simply wasteful of energy.

Operational Environment

Think about the environment in which the air compressor will work: Will it be taking a lot of heat, dust, or humidity shocks? A compressor constructed from strong and resistant material can tackle these events nicely. For industries where equipment is required to work in tough environments, there is a model such as the VIBRANT Fixed Speed Air Compressor that is best suited for industrial use.

Efficiency & Energy Use

Energy costs can be a percentage point of your operating cost and hence need to be controlled. Higher efficiency should be matched closely with lower energy consumption in the compressors to be purchased. New fixed-speed compressor models such as VIBRANT compressor use power effectively hence cutting longer operation costs.

Maintenance Needs

It is also important to consider the compressor that is easy to maintain, he or she should also be able to suggest the one that is easy to maintain. Electrical models such as the VIBRANT Fixed Speed Air Compressor require minimal maintenance and this guarantees your machines’ continuous operation. There are considerations of whether the model incorporates simple mechanisms such as disassembly or connection interfaces for convenient maintenance.

Pressure Stability

It is important for many kinds of industries to maintain stable pressure. An intelligent control system can be implemented on a compressor such that the exhaust pressure control is automatic to ensure a stable state. This feature makes it possible for your machines to run at optimum capacity all the time with no worry of a fade.

Why VIBRANT Fixed Speed Air Compressors?

They are an essential part of many industries and, when choosing the right one, make sure you buy air compressors from reputable manufacturers. Here’s why VIBRANT Fixed Speed Air Compressors stand out in the market:

Proven Quality and Innovation

VIBRANT compressors are built using the advanced technologies that fascinate a compressor and reliability. Being in compression air manufacturing for many years now VIBRANT has made its every model deal with industrial standards hence making it an ideal company.

Low Power, High Efficiency

VIBRANT Fixed Speed Air Compressors are recognized for their energy salvation capability. Meanwhile, these types of compressors pack a significant amount of power, though the manufacturers work hard to ensure these select an energy-efficient current. This means by using VIBRANT, industries can save a lot on the cost of energy and with no or very little compromise on performance.

Durability and Long Lifespan

As for VIBRANT compressors, we use the finest quality materials and they can be used often and roughly. These features make them strong enough to handle continued work without any chance of developing a fault, which is important in areas where system availability is a main priority. The compressors themselves are heavily built which makes it easier for them to last longer without the need for replacement.

Easy Maintenance

In their construction, VIBRANT Fixed Speed Air Compressors are designed in such a way that their maintenance is basic and easy. These efficient compressors have a modularity of components for easy fixing that in turn minimizes on time spent during repairs and the costs incurred. They also have a basic structure which means that there would be little to no interruption to your service.

Stability and Performance

Fully controlled by chip, VIBRANT compressors are able to vary exhaust pressure according to specific conditions. This exactness assures stable air pressure no matter the stages of operation; it increases the efficiency and duration of your systems.

Conclusion

In industrial settings, having a reliable and efficient air compressor is essential to ensure smooth operations and minimize downtime. VIBRANT Fixed Speed Air Compressor for industry provides all the benefits needed, including energy efficiency, durability, low maintenance, and consistent performance. Their advanced design and reliable control systems make them a top choice for industries that rely on continuous airflow for their machines. By investing in a VIBRANT Fixed Speed Air Compressor, you can optimize your productivity, reduce energy costs, and ensure long-term operational success.