5 HP Single Stage Air Compressor (PM VSD)

Air compressors that can help companies solve their problems.

Permanent Magnet Frequency Conversion Screw Air Compressor

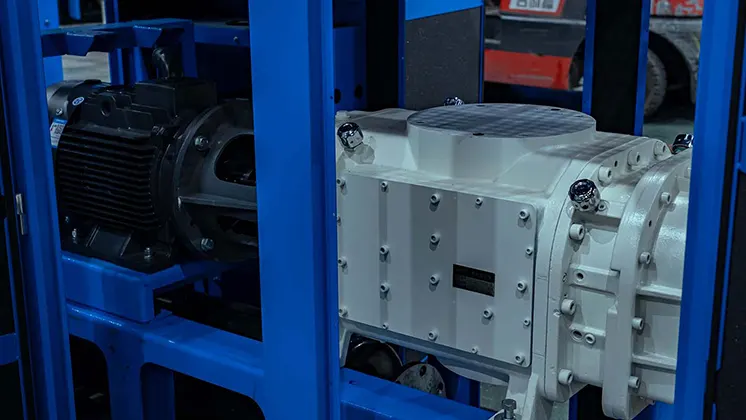

The 5 HP Single Stage Air Compressor – model no. JX-300APMS product is specifically being developed to meet the requirement of customers who require constant power to their tools such as air tools in various operations. The innovative element of this compressor is the ability to use single-stage operation to raise the capacity of air delivery and at the same time expand its simplicity in usage and maintenance. The JX-300APMS is highly built with great output to meet the requirement thoroughly, especially for works like; Workshops, Garage, and Industries that require Compressed Air for operating the pneumatic tools as well as pneumatic devices.

JX-300APMS

- Pressure(MPa): 0.8~1.3

- Exhaust Volume(m³/min): 38~28.8

- Power(KW/HP): 220/300

- Dimension(mm): 3550*2300*2300

- Weigt(kg): 5800

- Pipe Diameter: DN125

- Startup Mode: Variable Frequency Start

- Power Supply: Tree-phase 380V/50Hz , Can be customized

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

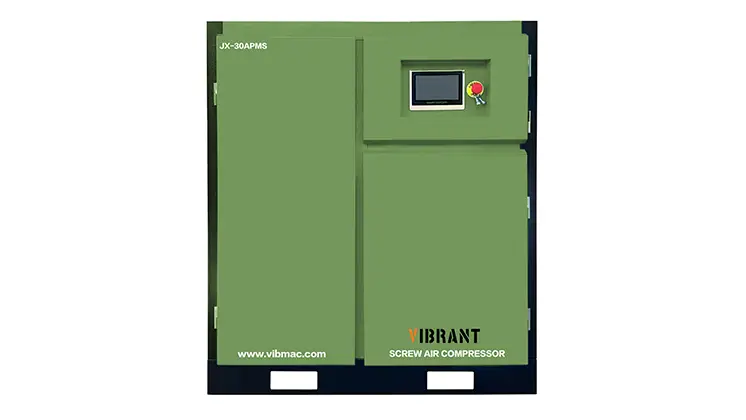

JX-30APMS-30HP/22KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 3.4~2.5

-

Power(KW/HP): 22/30

-

Dimension(mm): 1100*850*1110

-

Noise dB(A): ≤72±2

-

Weigt(kg): 420

-

Pipe Diameter: G1

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-40APMS-40HP/30KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 4.7~3.1

-

Power(KW/HP): 30/40

-

Dimension(mm): 1100*850*1110

-

Noise dB(A): ≤75±2

-

Weigt(kg): 450

-

Pipe Diameter: G1

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

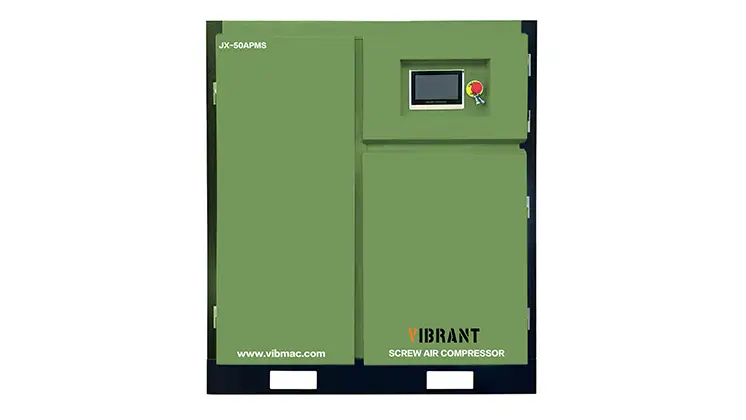

JX-50APMS-50HP/37KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 6.4~4.7

-

Power(KW/HP): 37/50

-

Dimension(mm): 1200*1000*1350

-

Noise dB(A): ≤77±2

-

Weigt(kg): 600

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-75APMS-75HP/55KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 9.4~6.2

-

Power(KW/HP): 55/75

-

Dimension(mm): 1500*1230*1550

-

Noise dB(A): ≤80±2

-

Weigt(kg): 850

-

Pipe Diameter: G2 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

JX-100APML2

-

Pressure(MPa): 1.6

-

FAD (m³/min): 9.0

-

Power(KW/HP): 75/100

VIEW MORE

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-100AS-100HP/75KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 12.4~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-10APML

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

Get In Touch

-1-696x1024.jpg)