60 Gallon Single Stage Air Compressor (PM VSD)

Air compressors that can help companies solve their problems.

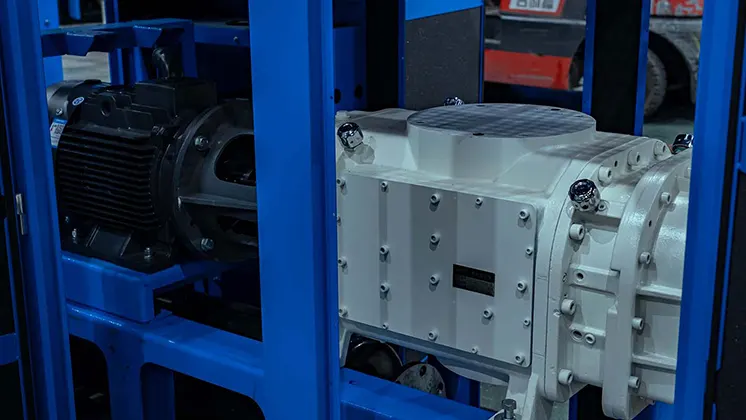

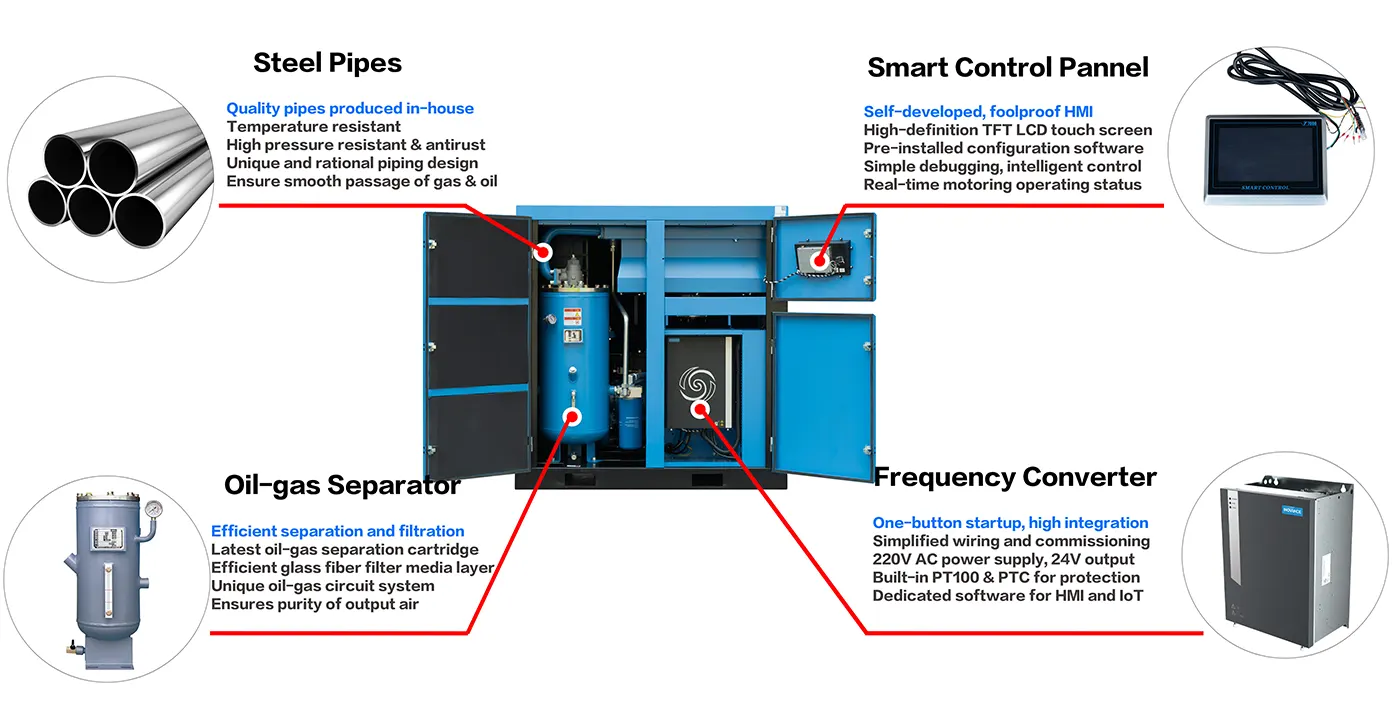

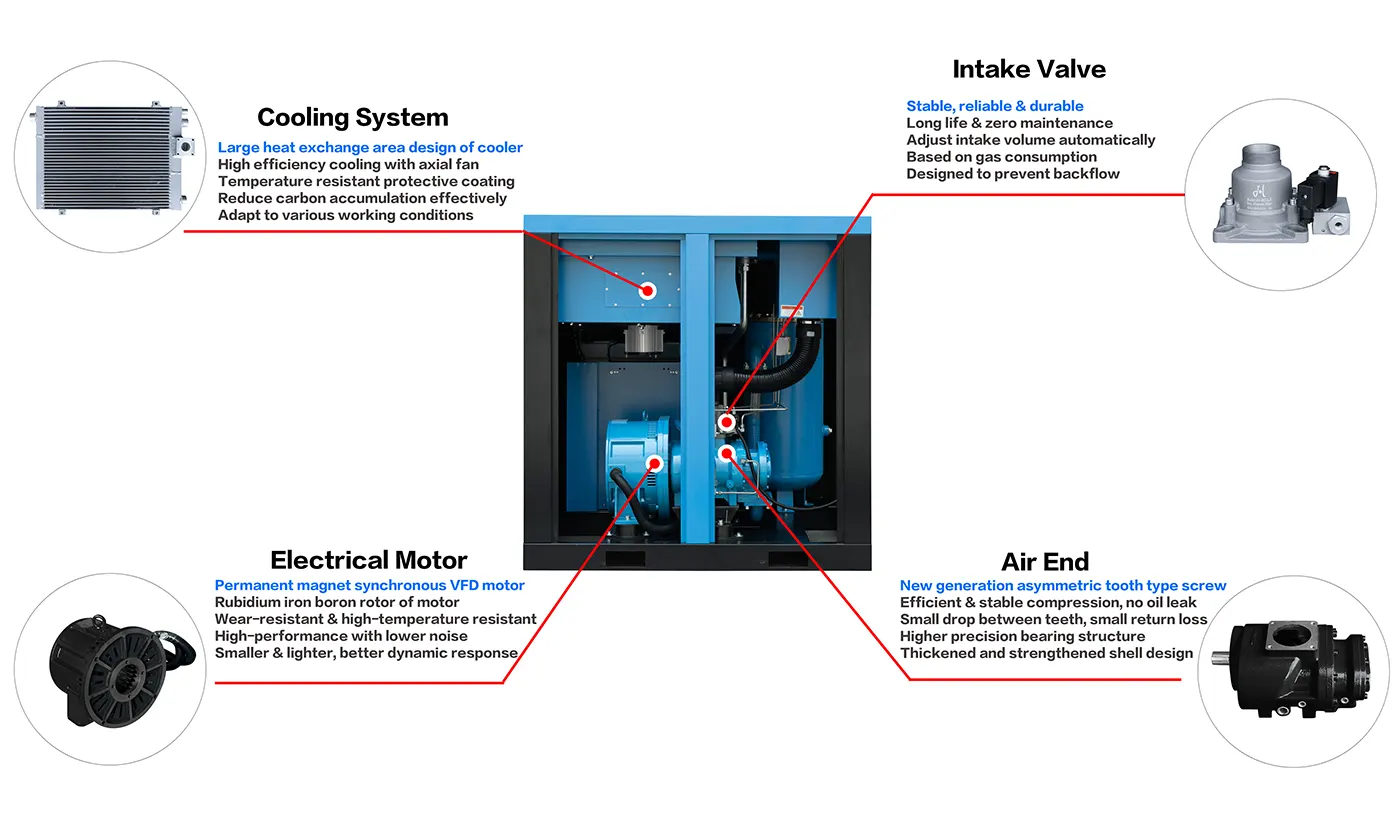

Permanent Magnet Frequency Conversion Screw Air Compressor

As for commercial use, the JX-270APMS 60 Gallon Single Stage Air Compressor is an efficient and durable model for commercial customers, as it is for industrial customers. This compressor is long lasting and performs at its best for it serves a variety of applications that require constant and continuous compressed air. Whether for use in powering the tools within a workshop or for more air for manufacturing requirements this compressor is dependable.

JX-270APMS

- Pressure(MPa): 0.8~1.3

- Exhaust Volume(m³/min): 32.5~25.5

- Power(KW/HP): 200/270

- Dimension(mm): 3550*2300*2300

- Weigt(kg): 5300

- Pipe Diameter: DN125

- Startup Mode: Variable Frequency Start

- Power Supply: Tree-phase 380V/50Hz , Can be customized

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

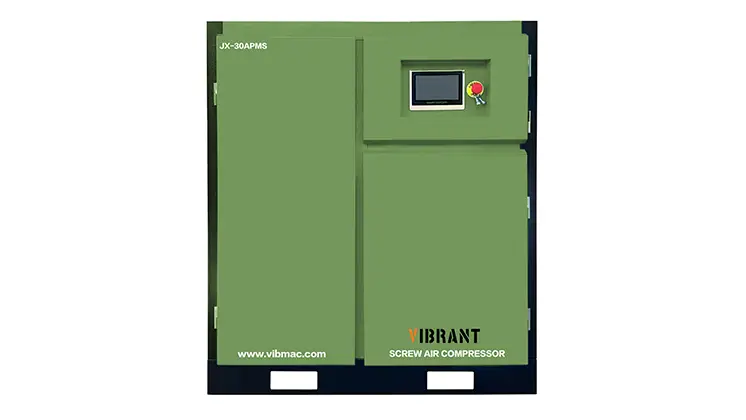

JX-30APMS-30HP/22KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 3.4~2.5

-

Power(KW/HP): 22/30

-

Dimension(mm): 1100*850*1110

-

Noise dB(A): ≤72±2

-

Weigt(kg): 420

-

Pipe Diameter: G1

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-40APMS-40HP/30KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 4.7~3.1

-

Power(KW/HP): 30/40

-

Dimension(mm): 1100*850*1110

-

Noise dB(A): ≤75±2

-

Weigt(kg): 450

-

Pipe Diameter: G1

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

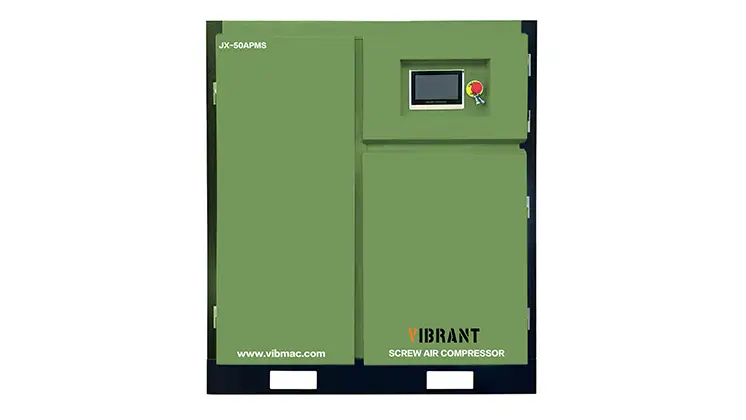

JX-50APMS-50HP/37KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 6.4~4.7

-

Power(KW/HP): 37/50

-

Dimension(mm): 1200*1000*1350

-

Noise dB(A): ≤77±2

-

Weigt(kg): 600

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-75APMS-75HP/55KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 9.4~6.2

-

Power(KW/HP): 55/75

-

Dimension(mm): 1500*1230*1550

-

Noise dB(A): ≤80±2

-

Weigt(kg): 850

-

Pipe Diameter: G2 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

JX-100APML2

-

Pressure(MPa): 1.6

-

FAD (m³/min): 9.0

-

Power(KW/HP): 75/100

VIEW MORE

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-100AS-100HP/75KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 12.4~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-10APML

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

Get In Touch

-1-696x1024.jpg)