80 Gallon Single Stage Air Compressor ( PM VSD)

Air compressors that can help companies solve their problems.

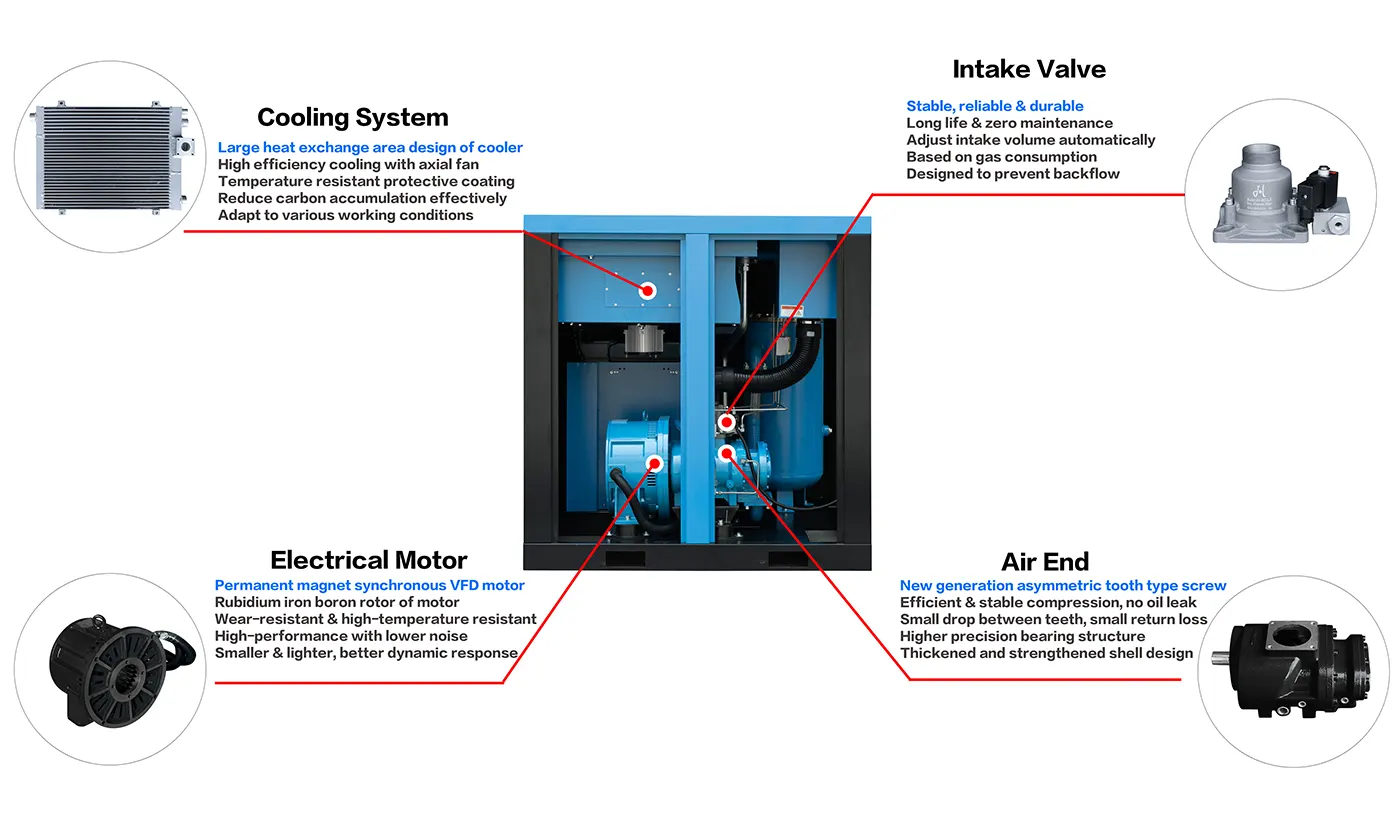

Permanent Magnet Frequency Conversion Screw Air Compressor

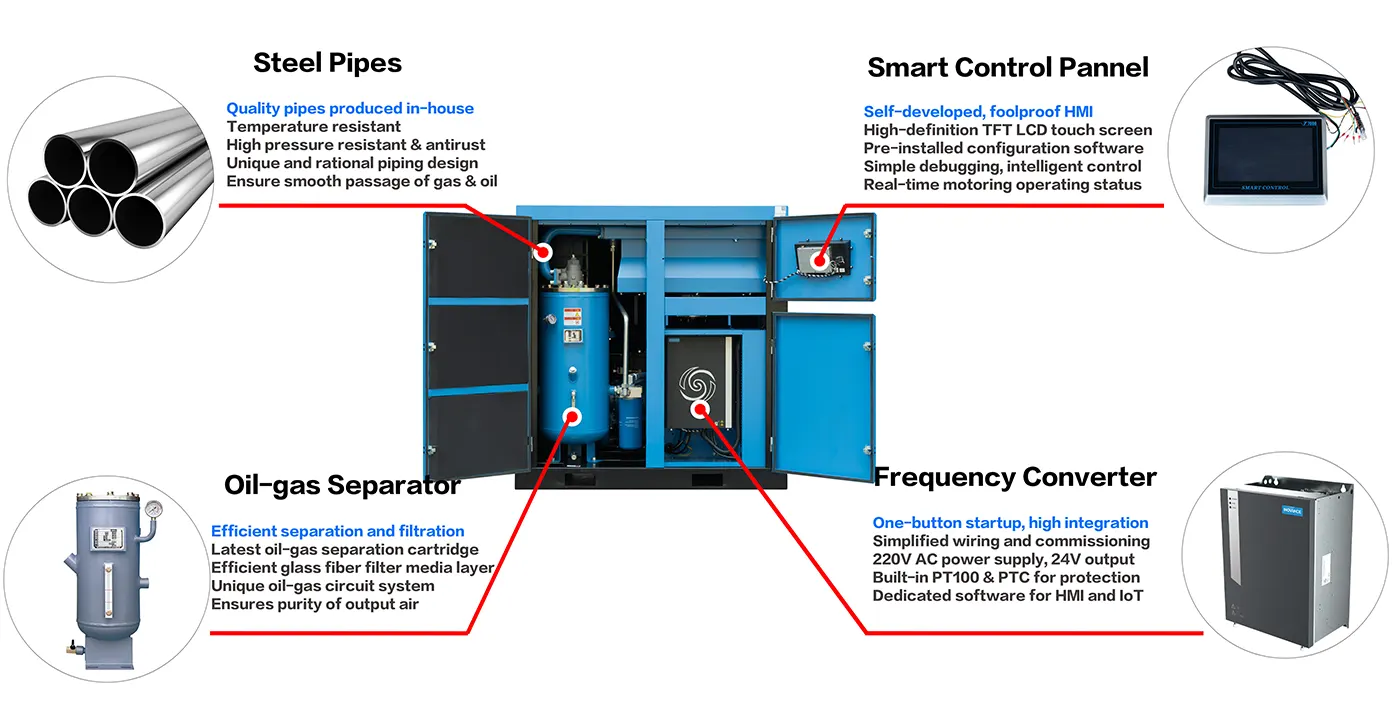

The JX-250APMS 80 Gallon Single Stage Air Compressor is a powerful and efficient air compressor that is used in industries that require a high quantity of air delivery. This compressor is of single-stage type and this, combined with high specifications affords a large volume of compressed air making it the fittest for environments that require high air compression.

JX-250APMS

- Pressure(MPa): 0.8~1.3

- Exhaust Volume(m³/min): 30~23

- Power(KW/HP): 185/250

- Dimension(mm): 3250*2100*2200

- Weigt(kg): 4200

- Pipe Diameter: DN100

- Startup Mode: Variable Frequency Start

- Power Supply: Tree-phase 380V/50Hz , Can be customized

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-180APMS

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 23~16

-

Power(KW/HP): 132/180

-

Dimension(mm): 2250*1510*1850

-

Weigt(kg): 2500

-

Pipe Diameter: DN65

-

Startup Mode: Variable Frequency Start

-

Power Supply: Tree-phase 380V/50Hz , Can be customized

VIEW MORE

JX-220APMS

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 28.5~21.5

-

Power(KW/HP): 160/220

-

Dimension(mm): 3250*2100*2200

-

Weigt(kg): 4000

-

Pipe Diameter: DN100

-

Startup Mode: Variable Frequency Start

-

Power Supply: Tree-phase 380V/50Hz , Can be customized

VIEW MORE

JX-250APMS

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 30~23

-

Power(KW/HP): 185/250

-

Dimension(mm): 3250*2100*2200

-

Weigt(kg): 4200

-

Pipe Diameter: DN100

-

Startup Mode: Variable Frequency Start

-

Power Supply: Tree-phase 380V/50Hz , Can be customized

VIEW MORE

JX-150APMS

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 19.9~14.5

-

Power(KW/HP): 110/150

-

Dimension(mm): 2250*1510*1850

-

Weigt(kg): 2300

-

Pipe Diameter: DN65

-

Startup Mode: Variable Frequency Start

-

Power Supply: Tree-phase 380V/50Hz , Can be customized

VIEW MORE

You May Also Like

JX-100APML2

-

Pressure(MPa): 1.6

-

FAD (m³/min): 9.0

-

Power(KW/HP): 75/100

VIEW MORE

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-100AS-100HP/75KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 12.4~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-10APML

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

Get In Touch

-1-696x1024.jpg)