Two Stage Or Single Stage Air Compressor (PM VSD)

Air compressors that can help companies solve their problems.

Permanent Magnet Frequency Conversion Screw Air Compressor

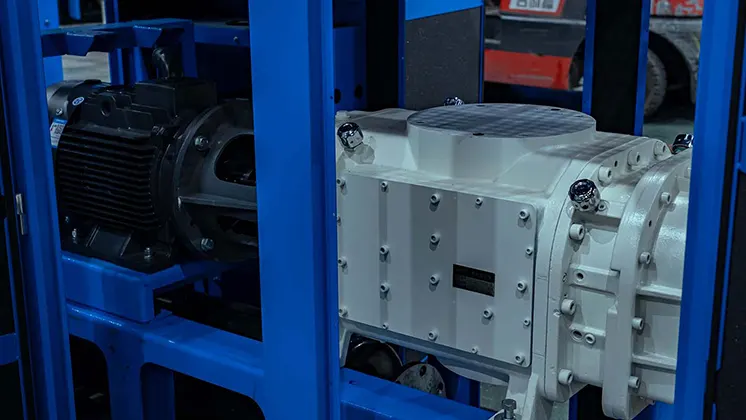

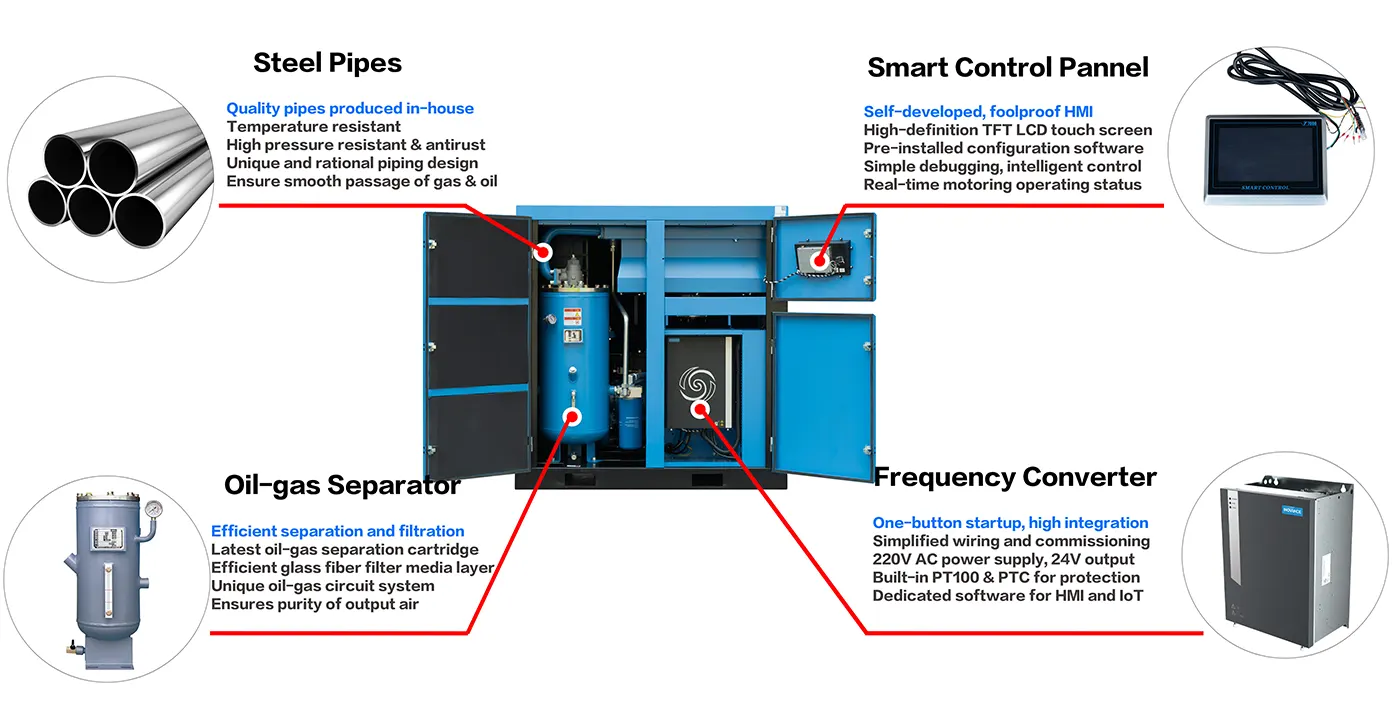

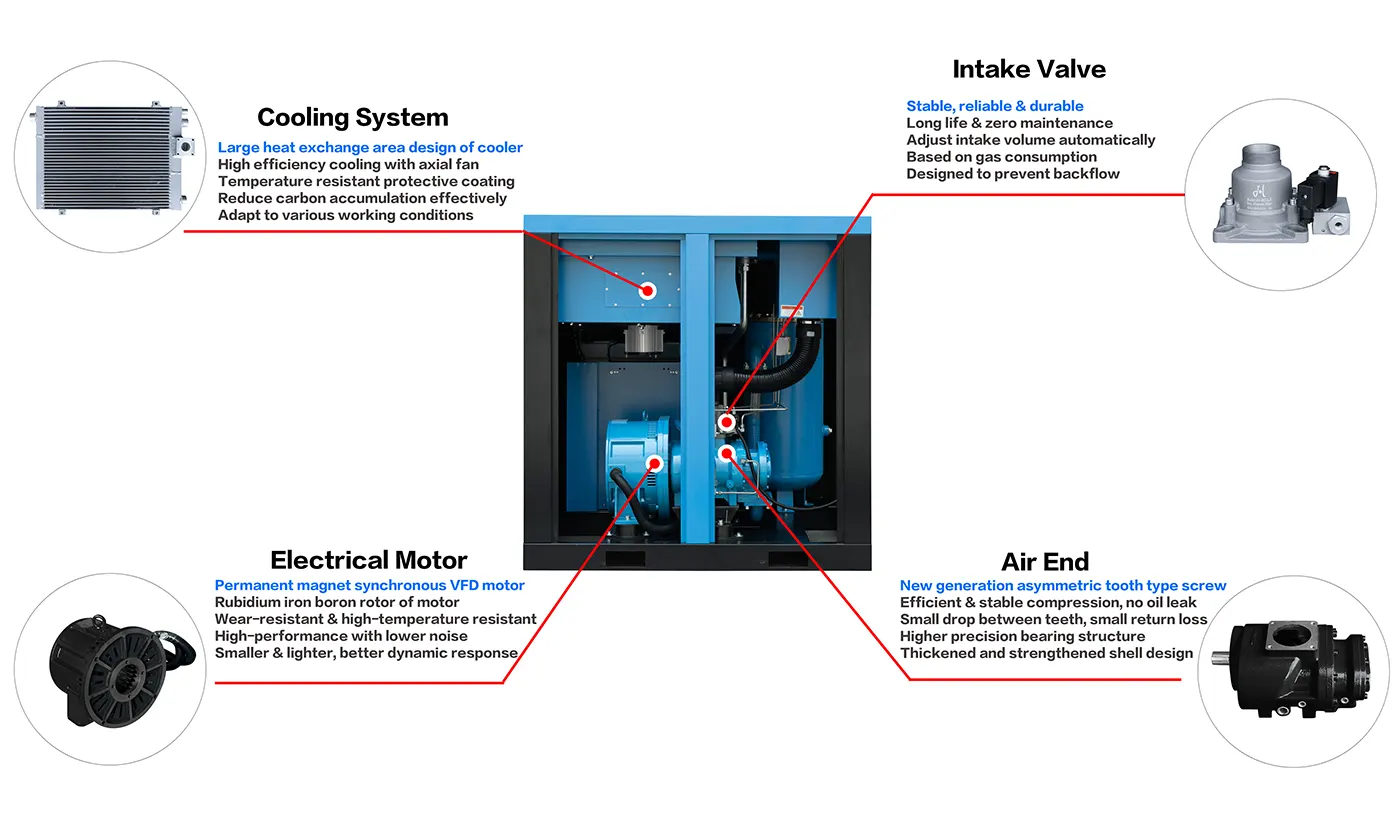

JX 220APMS Two Stage Or Single Stage Air Compressor on offer is designed with flexibility in mind, being that one can use either single or two-stage compression depending on one’s needs in a particular industrial setting. This advanced compressor is highly suitable for conventional application wherein reliable and adjustable pressure is preferable.

JX-220APMS

- Pressure(MPa): 0.8~1.3

- Exhaust Volume(m³/min): 28.5~21.5

- Power(KW/HP): 160/220

- Dimension(mm): 3250*2100*2200

- Weigt(kg): 4000

- Pipe Diameter: DN100

- Startup Mode: Variable Frequency Start

- Power Supply: Tree-phase 380V/50Hz , Can be customized

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

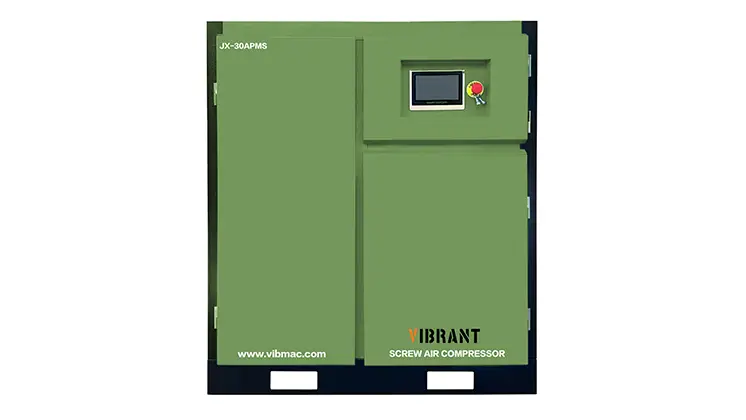

JX-30APMS-30HP/22KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 3.4~2.5

-

Power(KW/HP): 22/30

-

Dimension(mm): 1100*850*1110

-

Noise dB(A): ≤72±2

-

Weigt(kg): 420

-

Pipe Diameter: G1

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-40APMS-40HP/30KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 4.7~3.1

-

Power(KW/HP): 30/40

-

Dimension(mm): 1100*850*1110

-

Noise dB(A): ≤75±2

-

Weigt(kg): 450

-

Pipe Diameter: G1

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

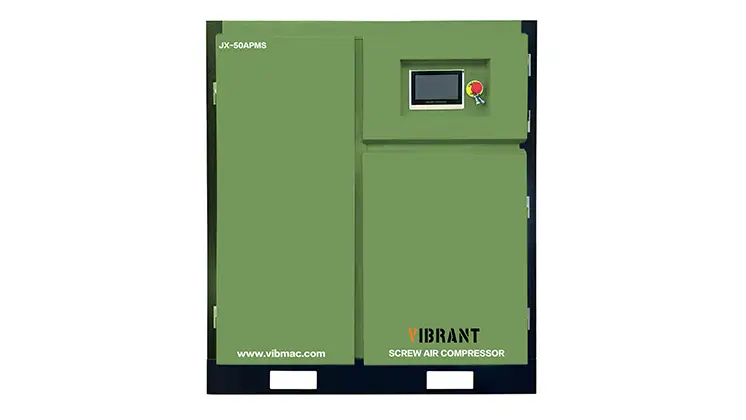

JX-50APMS-50HP/37KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 6.4~4.7

-

Power(KW/HP): 37/50

-

Dimension(mm): 1200*1000*1350

-

Noise dB(A): ≤77±2

-

Weigt(kg): 600

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-75APMS-75HP/55KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 9.4~6.2

-

Power(KW/HP): 55/75

-

Dimension(mm): 1500*1230*1550

-

Noise dB(A): ≤80±2

-

Weigt(kg): 850

-

Pipe Diameter: G2 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

JX-100APML2

-

Pressure(MPa): 1.6

-

FAD (m³/min): 9.0

-

Power(KW/HP): 75/100

VIEW MORE

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-100AS-100HP/75KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 12.4~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-10APML

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

Get In Touch

-1-696x1024.jpg)