Single Stage Air Compressor Pump (PM VSD JX-180APMS

Air compressors that can help companies solve their problems.

Permanent Magnet Frequency Conversion Screw Air Compressor

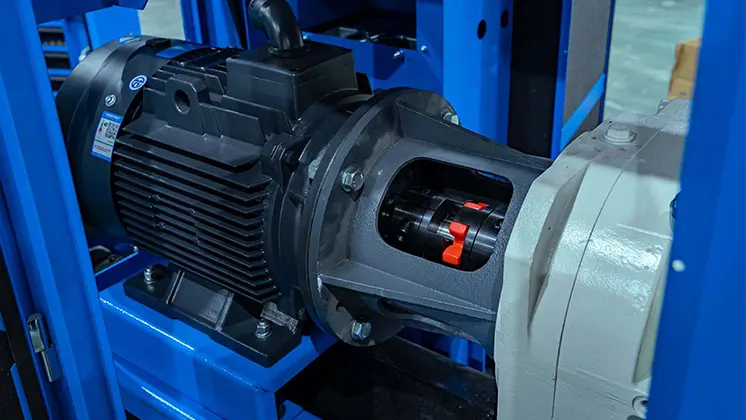

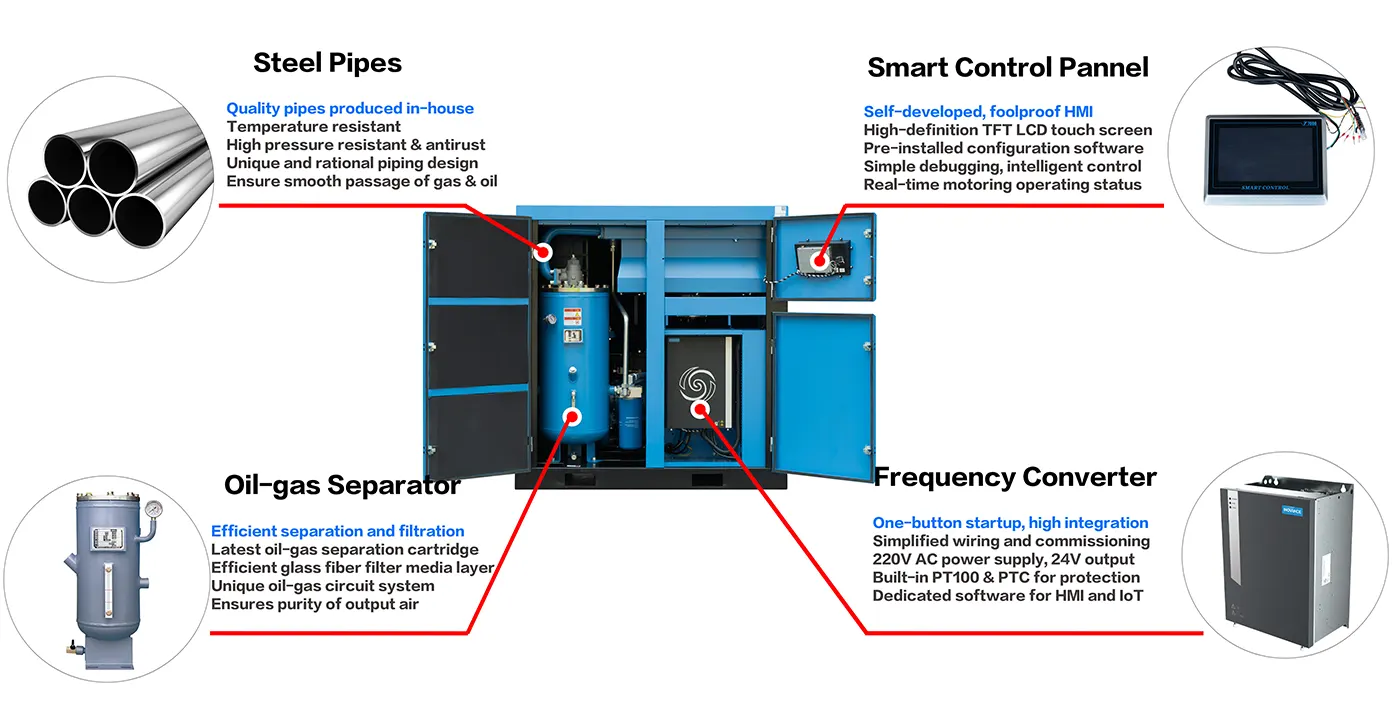

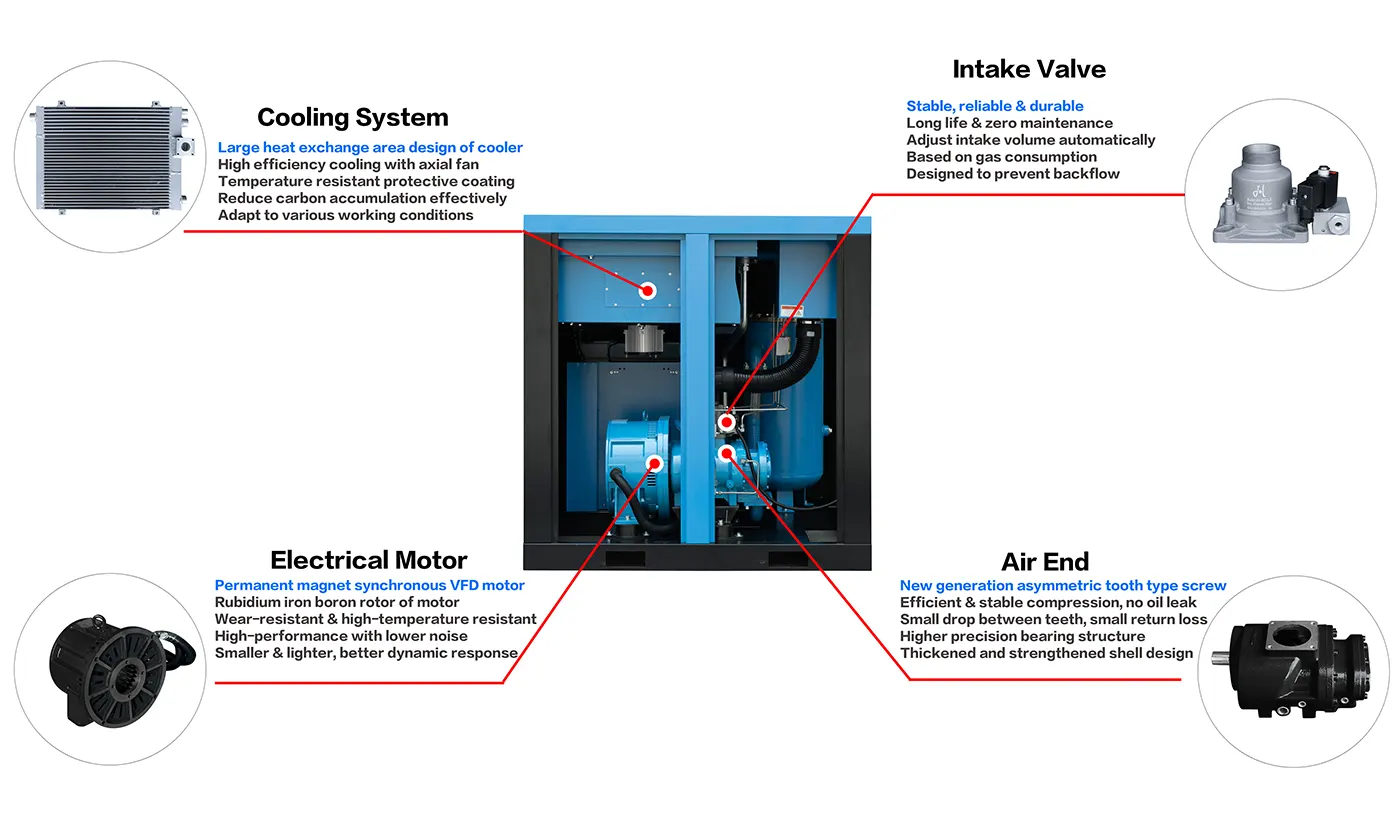

The JX-180APMS Single Stage Air Compressor Pump is a single-stage compression unit, which is energy efficient with Variable Speed Drive (VSD) for more operational flexibility in various industrial processes. It is developed to provide constant, customizable, and stable air pressure and volume of air flow which makes it appropriate for all industries that demand consistent air supply.

JX-180APMS

- Pressure(MPa): 0.8~1.3

- Exhaust Volume(m³/min): 23~16

- Power(KW/HP): 132/180

- Dimension(mm): 2250*1510*1850

- Weigt(kg): 2500

- Pipe Diameter: DN65

- Startup Mode: Variable Frequency Start

- Power Supply: Tree-phase 380V/50Hz , Can be customized

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

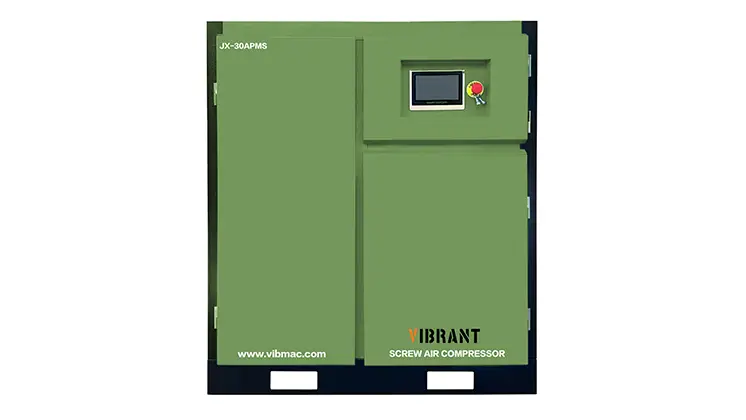

JX-30APMS-30HP/22KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 3.4~2.5

-

Power(KW/HP): 22/30

-

Dimension(mm): 1100*850*1110

-

Noise dB(A): ≤72±2

-

Weigt(kg): 420

-

Pipe Diameter: G1

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-40APMS-40HP/30KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 4.7~3.1

-

Power(KW/HP): 30/40

-

Dimension(mm): 1100*850*1110

-

Noise dB(A): ≤75±2

-

Weigt(kg): 450

-

Pipe Diameter: G1

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

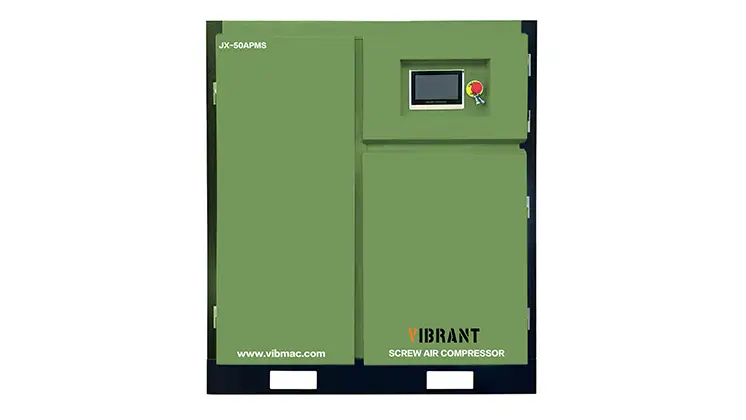

JX-50APMS-50HP/37KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 6.4~4.7

-

Power(KW/HP): 37/50

-

Dimension(mm): 1200*1000*1350

-

Noise dB(A): ≤77±2

-

Weigt(kg): 600

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-75APMS-75HP/55KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 9.4~6.2

-

Power(KW/HP): 55/75

-

Dimension(mm): 1500*1230*1550

-

Noise dB(A): ≤80±2

-

Weigt(kg): 850

-

Pipe Diameter: G2 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

JX-100APML2

-

Pressure(MPa): 1.6

-

FAD (m³/min): 9.0

-

Power(KW/HP): 75/100

VIEW MORE

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-100AS-100HP/75KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 12.4~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-10APML

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

Get In Touch

-1-696x1024.jpg)