Electric Air Compressor

Air compressors that can help companies solve their problems.

Permanent Magnet Frequency Conversion Screw Air Compressor

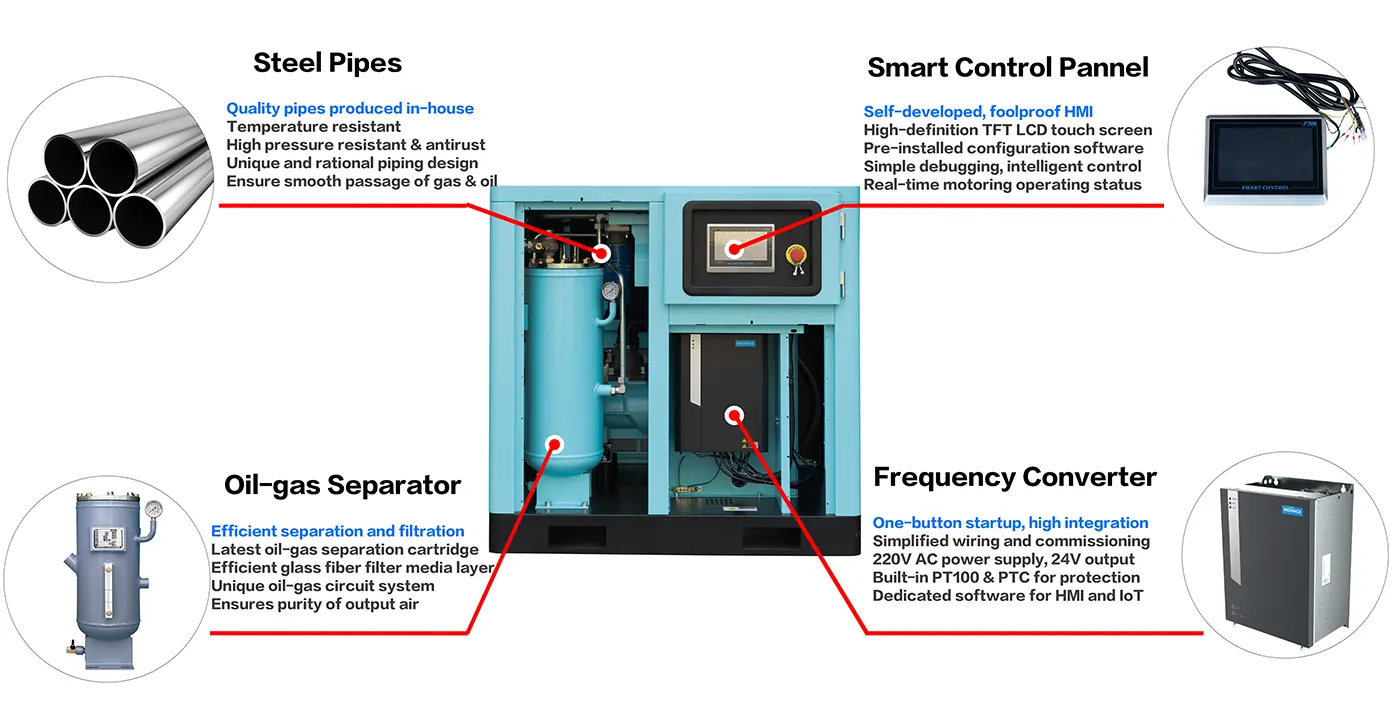

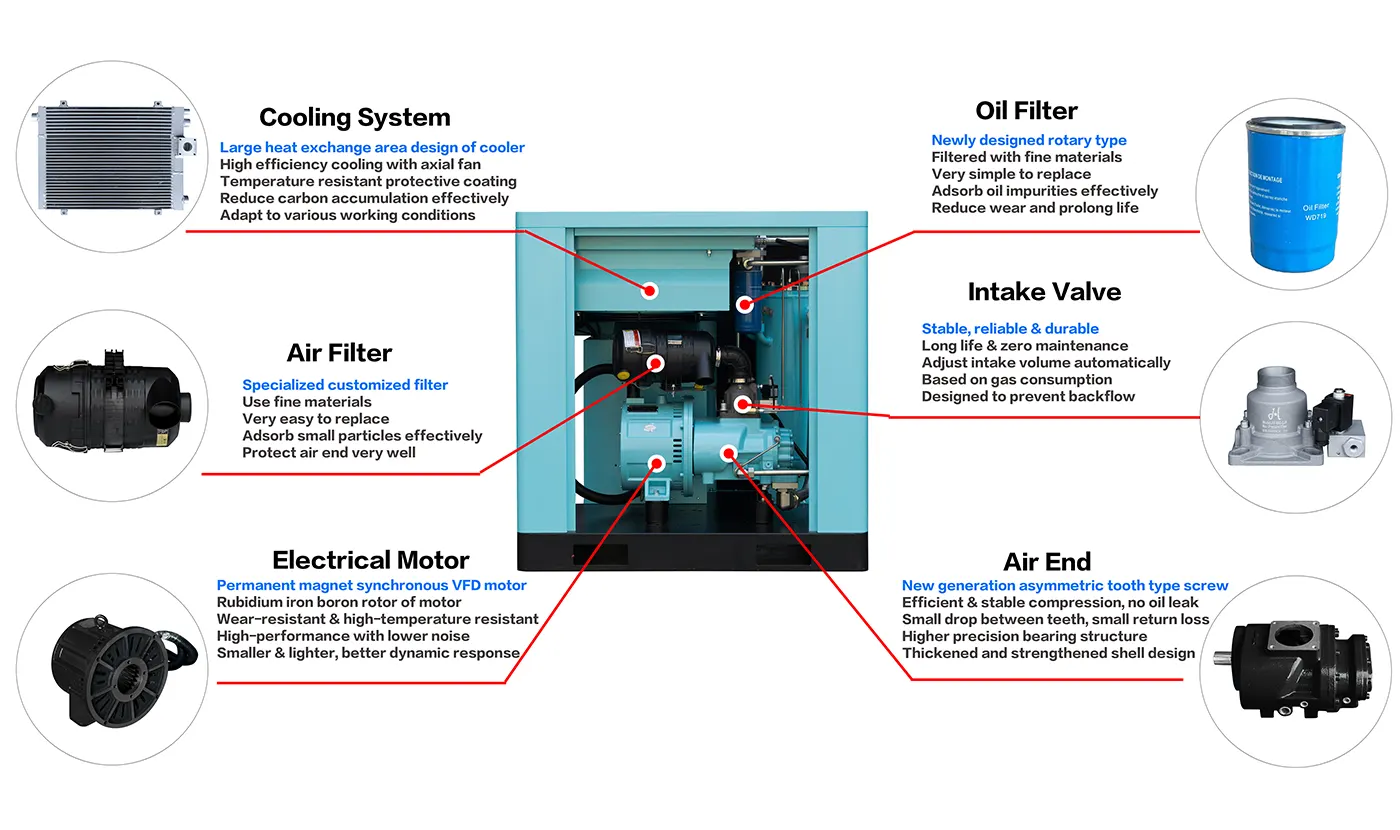

JX-250APMX Electric Air Compressor is a high-pressure model, Industrial grade air compressor that generates a reliable large volume of air required for different operations. The electric motor is used in the design to provide relatively high levels of efficiency and output consistency, which is going to be important if you require air compression on the spot in your work. High-quality and suitable for various industries with various operations that need a steady air supply; this product is strong and diversified.

JX-250APMX

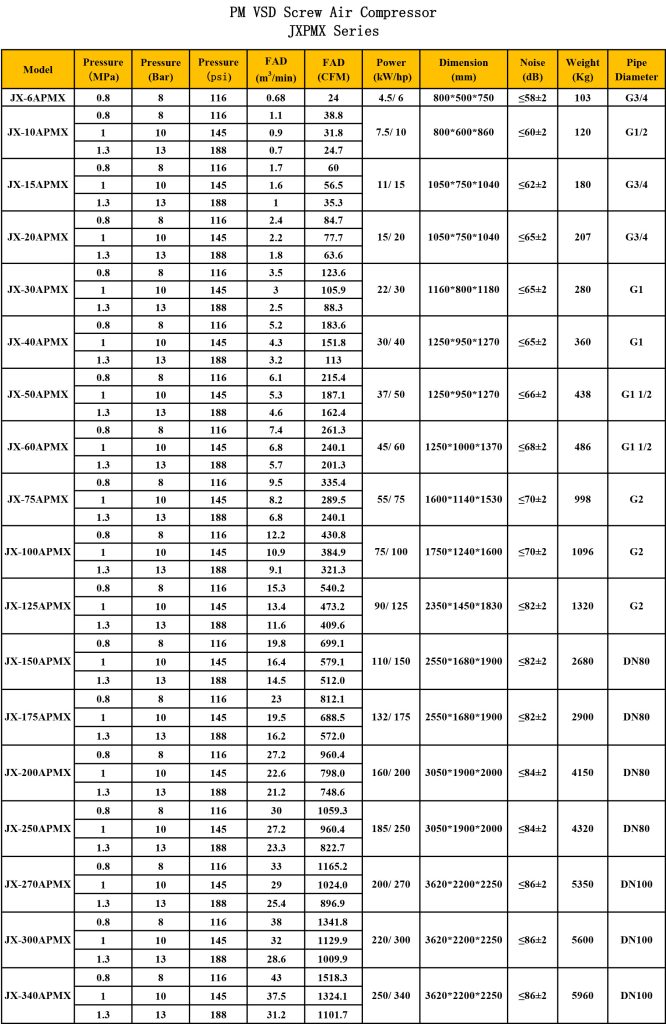

- Pressure(MPa): 0.8~1.3

- Exhaust Volume(m³/min): 30~23.3

- Power(KW/HP): 185/ 250

- Dimension(mm): 3050*1900*2000

- Noise dB(A): ≤84±2

- Weigt(kg): 4320

- Pipe Diameter: DN80

- Startup Mode: Frequency Conversion Start

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-50APMX-37KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 6.1~4.6

-

Power(KW/HP): 37/50

-

Dimension(mm): 1250*950*1290

-

Noise dB(A): ≤66±2

-

Weigt(kg): 438

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-60APMX-45KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 7.4~5.7

-

Power(KW/HP): 45/60

-

Dimension(mm): 1250*1000*1370

-

Noise dB(A): ≤68±2

-

Weigt(kg): 486

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-75APMX-55KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 9.5~6.8

-

Power(KW/HP): 55/75

-

Dimension(mm): 1600*1140*1530

-

Noise dB(A): ≤70±2

-

Weigt(kg): 998

-

Pipe Diameter: G2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-20APMX-15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.4~1.8

-

Power(KW/HP): 15/20

-

Dimension(mm): 1050*750*1060

-

Noise dB(A): ≤65±2

-

Weigt(kg): 207

-

Pipe Diameter: G3/4

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

B-X10A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.1

-

Power(KW/HP): 7.5/10

VIEW MORE

B-XG10A

-

Pressure(MPa): 1.2-1.5

-

Exhaust Volume(m³/min): 0.7-0.63

-

Power(KW/HP): 7.5/10

VIEW MORE

JX-100APML2

-

Pressure(MPa): 1.6

-

FAD (m³/min): 9.0

-

Power(KW/HP): 75/100

VIEW MORE

JX-100APMS-100HP/75KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 12.3

-

Power(KW/HP): 75/100

VIEW MORE

Get In Touch