PM Drilling Air Compressor

Air compressors that can help companies solve their problems.

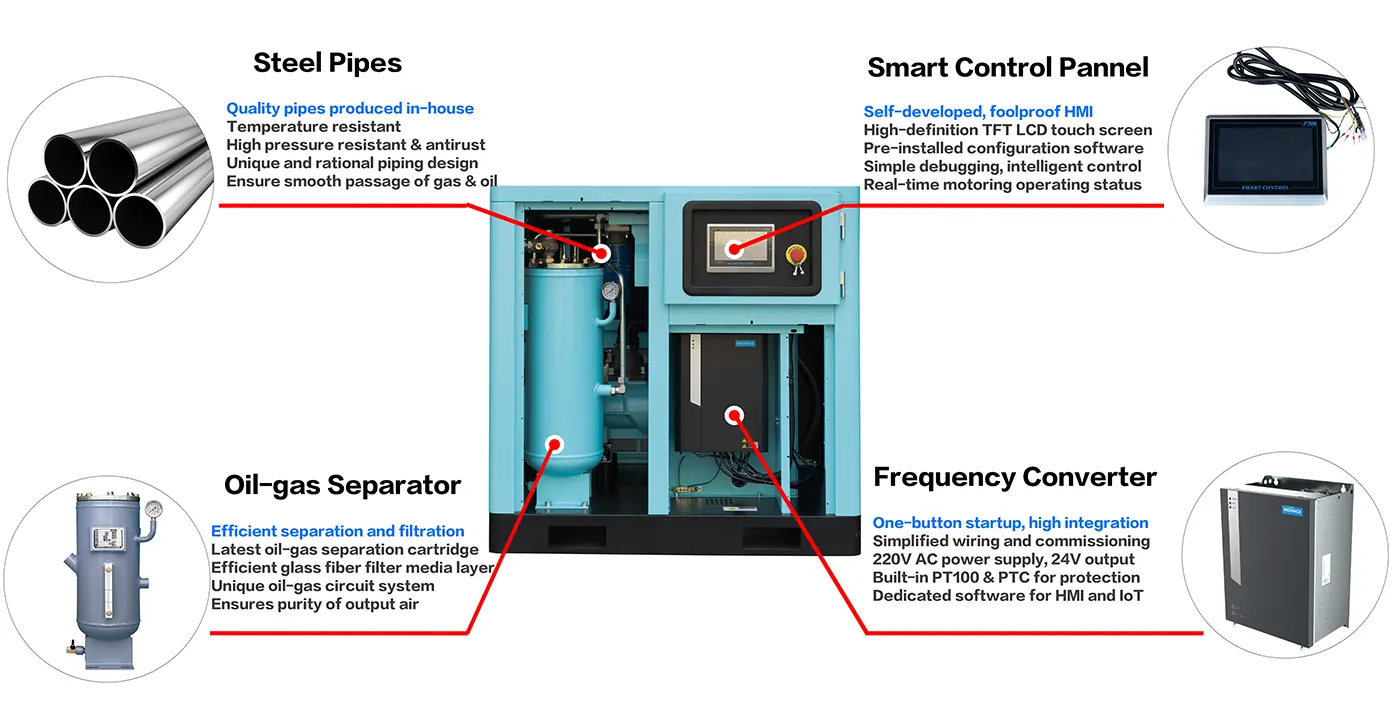

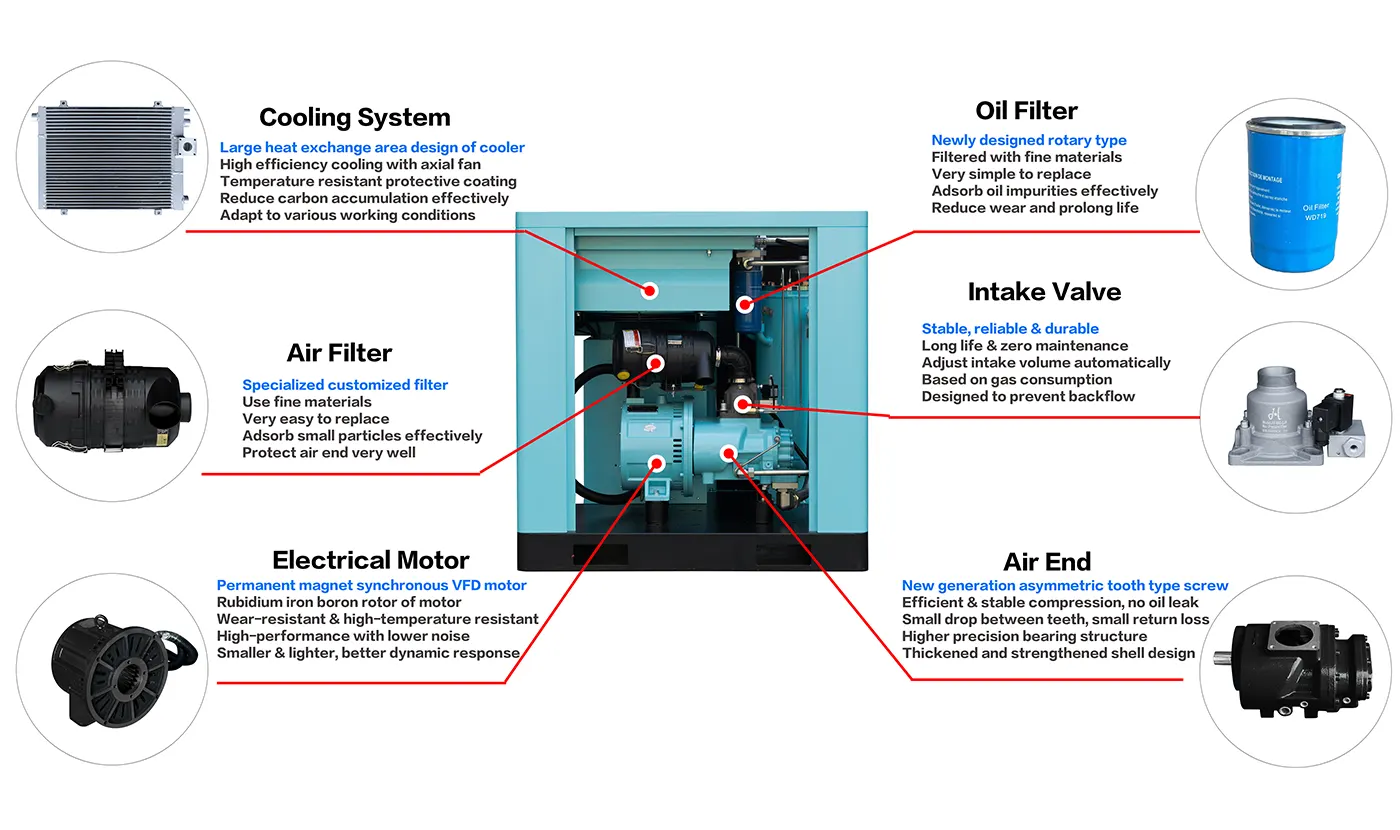

Permanent Magnet Frequency Conversion Screw Air Compressor

The JX-200APMX PM Drilling Air Compressor is primarily an advanced air compressor suitable for drilling types of operations. The performances of this multi-stage and high-pressure intense air screw are guaranteed to provide steady flows of compressed air at different working pressures, therefore it can best be used in mining área, construction, and even exploration of oil.

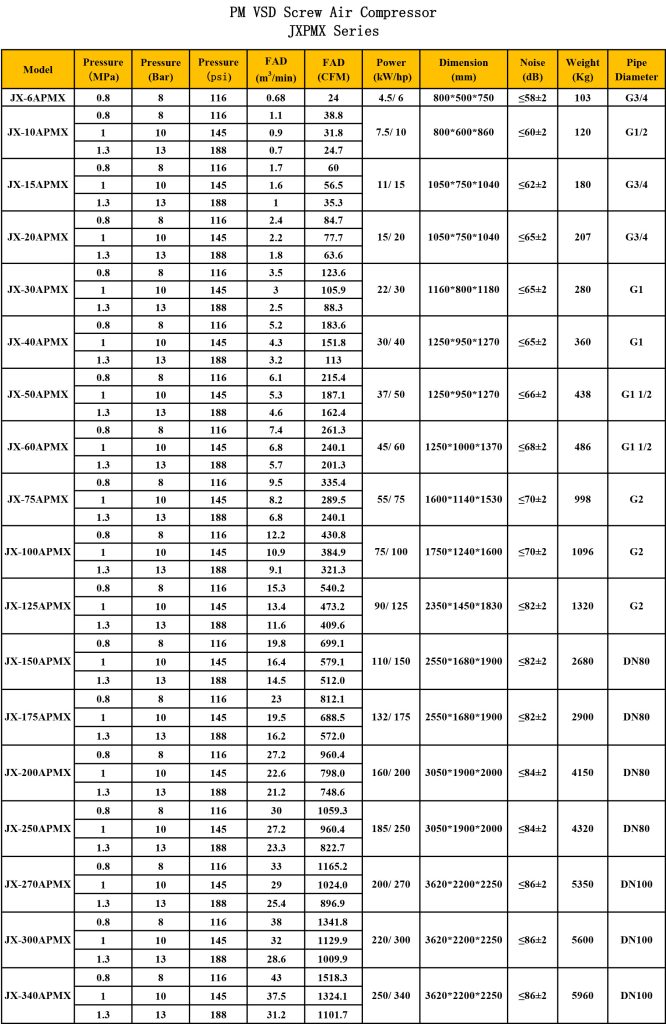

JX-200APMX

- Pressure(MPa): 0.8~1.3

- Exhaust Volume(m³/min): 27.2~21.2

- Power(KW/HP): 160/ 200

- Dimension(mm): 3050*1900*2000

- Noise dB(A): ≤84±2

- Weigt(kg): 4150

- Pipe Diameter: DN80

- Startup Mode: Frequency Conversion Start

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-50APMX-37KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 6.1~4.6

-

Power(KW/HP): 37/50

-

Dimension(mm): 1250*950*1290

-

Noise dB(A): ≤66±2

-

Weigt(kg): 438

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-60APMX-45KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 7.4~5.7

-

Power(KW/HP): 45/60

-

Dimension(mm): 1250*1000*1370

-

Noise dB(A): ≤68±2

-

Weigt(kg): 486

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-75APMX-55KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 9.5~6.8

-

Power(KW/HP): 55/75

-

Dimension(mm): 1600*1140*1530

-

Noise dB(A): ≤70±2

-

Weigt(kg): 998

-

Pipe Diameter: G2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-20APMX-15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.4~1.8

-

Power(KW/HP): 15/20

-

Dimension(mm): 1050*750*1060

-

Noise dB(A): ≤65±2

-

Weigt(kg): 207

-

Pipe Diameter: G3/4

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

B-X10A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.1

-

Power(KW/HP): 7.5/10

VIEW MORE

B-XG10A

-

Pressure(MPa): 1.2-1.5

-

Exhaust Volume(m³/min): 0.7-0.63

-

Power(KW/HP): 7.5/10

VIEW MORE

JX-100APML2

-

Pressure(MPa): 1.6

-

FAD (m³/min): 9.0

-

Power(KW/HP): 75/100

VIEW MORE

JX-100APMS-100HP/75KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 12.3

-

Power(KW/HP): 75/100

VIEW MORE

Get In Touch