PM VSD Compressor Manufacturers

Air compressors that can help companies solve their problems.

Permanent Magnet Frequency Conversion Screw Air Compressor

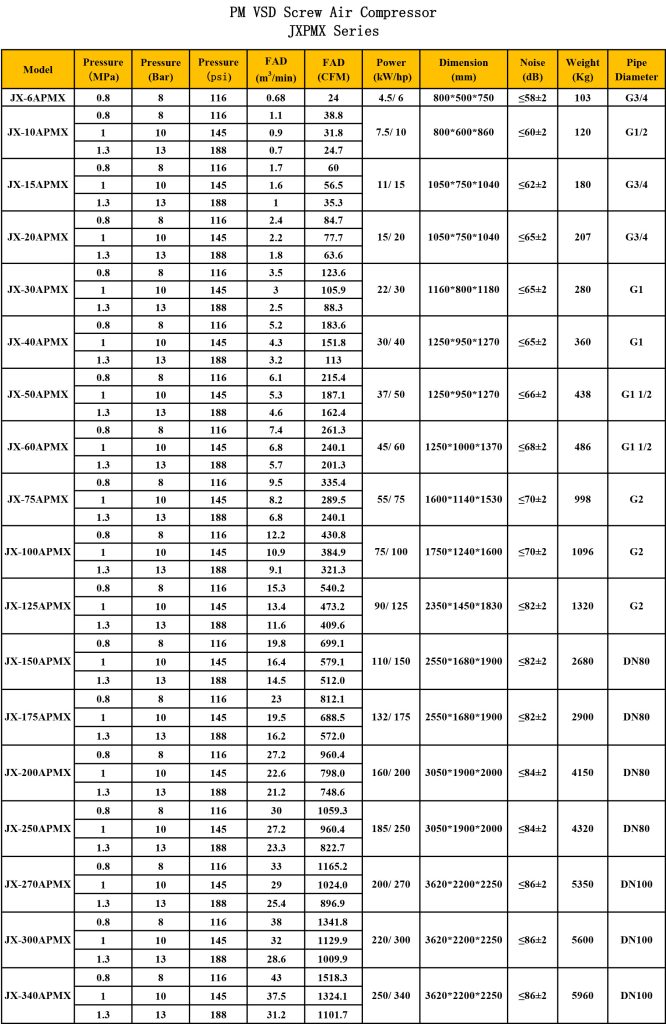

The requirements for medium and large factory air compression are high, and the largest exhaust volume and exhaust pressure are obtained from the JX-125APMX screw air compressor. The constant stream of power supply enables control of process flow, efficiency during production, and safety of operation. Combined with its high output, 125 HP (90 kW) motor, and state-of-the-art technology this compressor is well-equipped for multiple industries’ needs as well as energy-saving and service life advantages.

JX-125APMX

- Pressure(MPa): 0.8~1.3

- Exhaust Volume(m³/min): 15.3~11.6

- Power(KW/HP): 90/125

- Dimension(mm): 2350*1450*1830

- Noise dB(A): ≤82±2

- Weigt(kg): 1320

- Pipe Diameter: G2

- Startup Mode: Frequency Conversion Start

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-50APMX-37KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 6.1~4.6

-

Power(KW/HP): 37/50

-

Dimension(mm): 1250*950*1290

-

Noise dB(A): ≤66±2

-

Weigt(kg): 438

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-60APMX-45KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 7.4~5.7

-

Power(KW/HP): 45/60

-

Dimension(mm): 1250*1000*1370

-

Noise dB(A): ≤68±2

-

Weigt(kg): 486

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-75APMX-55KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 9.5~6.8

-

Power(KW/HP): 55/75

-

Dimension(mm): 1600*1140*1530

-

Noise dB(A): ≤70±2

-

Weigt(kg): 998

-

Pipe Diameter: G2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-20APMX-15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.4~1.8

-

Power(KW/HP): 15/20

-

Dimension(mm): 1050*750*1060

-

Noise dB(A): ≤65±2

-

Weigt(kg): 207

-

Pipe Diameter: G3/4

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

B-X10A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.1

-

Power(KW/HP): 7.5/10

VIEW MORE

B-XG10A

-

Pressure(MPa): 1.2-1.5

-

Exhaust Volume(m³/min): 0.7-0.63

-

Power(KW/HP): 7.5/10

VIEW MORE

JX-100APML2

-

Pressure(MPa): 1.6

-

FAD (m³/min): 9.0

-

Power(KW/HP): 75/100

VIEW MORE

JX-100APMS-100HP/75KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 12.3

-

Power(KW/HP): 75/100

VIEW MORE

Get In Touch