400 Cfm Fixed Speed Electric Air Compressor

Air compressors that can help companies solve their problems.

Fixed Speed Air Compressor

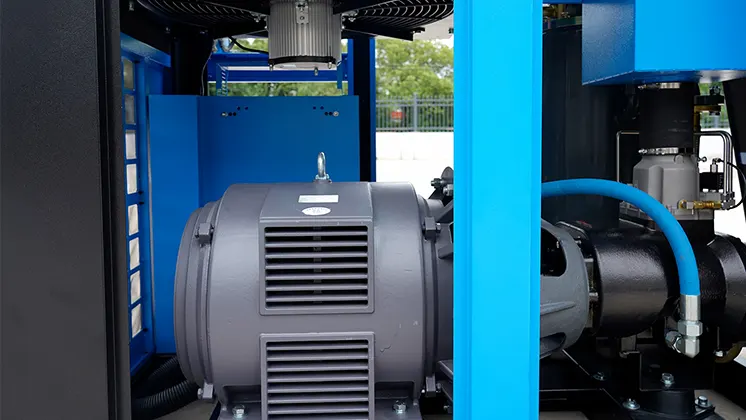

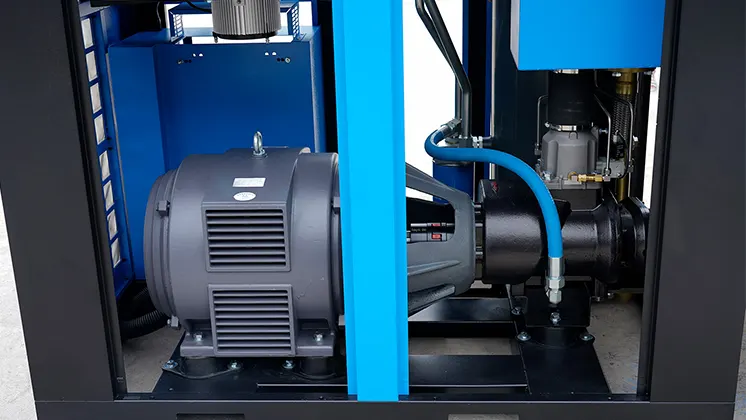

The 400 CFM Fixed Speed Electric Air Compressor – JX-300AS is intended for commercial use where cost-effectiveness, stability, and high operating capacity are required. This electric compressor has a fixed-speed motor so it produces constant volumes of compressed air it is suitable for several operations in manufacturing, and construction among others. Through its solid structure and sophisticated technologies, the JX-300AS guarantees durability and productivity in the severest conditions.

JX-300AS

- Pressure(MPa): 0.7~1.3

- Exhaust Volume(m³/min): 42~28.5

- Power(KW/HP): 220/300

- Dimension(mm): 3550*2300*2300

- Weigt(kg): 5000

- Pipe Diameter: DN125

- Startup Mode: Direct Start

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-40AS-40HP-30KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 4.7~3.1

-

Power(KW/HP): 30/40

-

Dimension(mm): 1350*850*1110

-

Noise dB(A): ≤72±2

-

Weigt(kg): 460

-

Pipe Diameter: G1

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-50AS-50HP-37KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 6.4~4.7

-

Power(KW/HP): 37/50

-

Dimension(mm): 1500*1000*1350

-

Noise dB(A): ≤78±2

-

Weigt(kg): 650

-

Pipe Diameter: G1 1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-60AS-60HP-45KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 7.3~6.2

-

Power(KW/HP): 45/60

-

Dimension(mm): 1500*1000*1350

-

Noise dB(A): ≤78±2

-

Weigt(kg): 700

-

Pipe Diameter: G1 1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

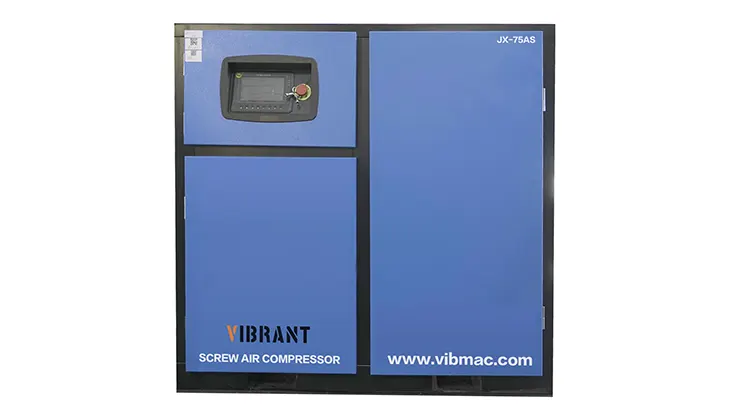

JX-75AS-55KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 9.4~6.1

-

Power(KW/HP): 55/75

-

Dimension(mm): 1700*1210*1550

-

Noise dB(A): ≤80±2

-

Weigt(kg): 1100

-

Pipe Diameter: G2 1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

B-X10A-16

-

Pressure(MPa): 1.6

-

Exhaust Volume(m³/min): 0.5

-

Power(KW/HP): 7.5/10

VIEW MORE

B-XG10A

-

Pressure(MPa): 1.2-1.5

-

Exhaust Volume(m³/min): 0.7-0.63

-

Power(KW/HP): 7.5/10

VIEW MORE

JX-100APML2

-

Pressure(MPa): 1.6

-

FAD (m³/min): 9.0

-

Power(KW/HP): 75/100

VIEW MORE

JX-10APML

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

Get In Touch