Two Stage 80 Gallon Air Compressor

Perfect choice for air solution!

Two Stage Air Compressors

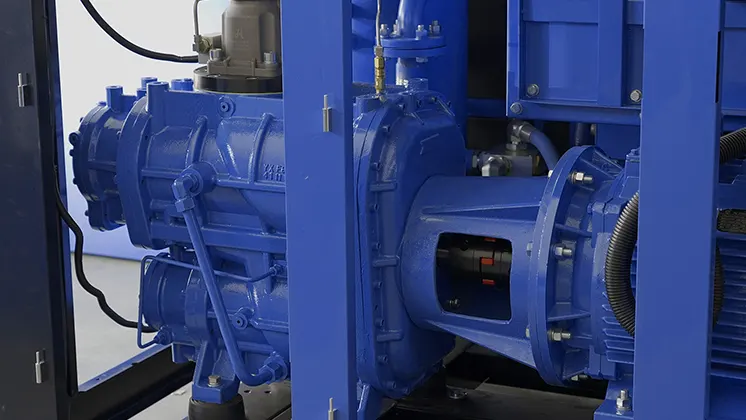

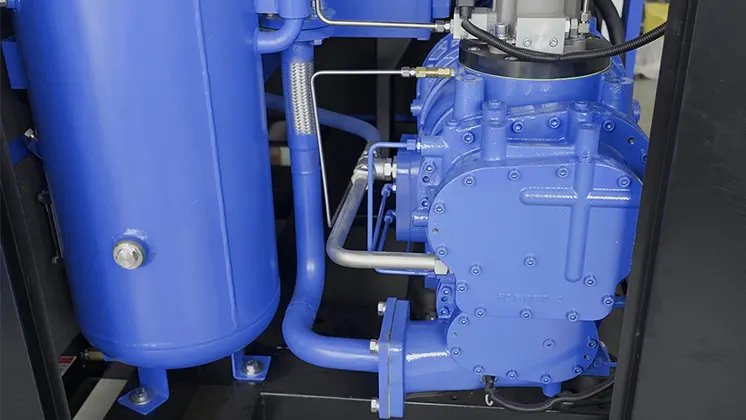

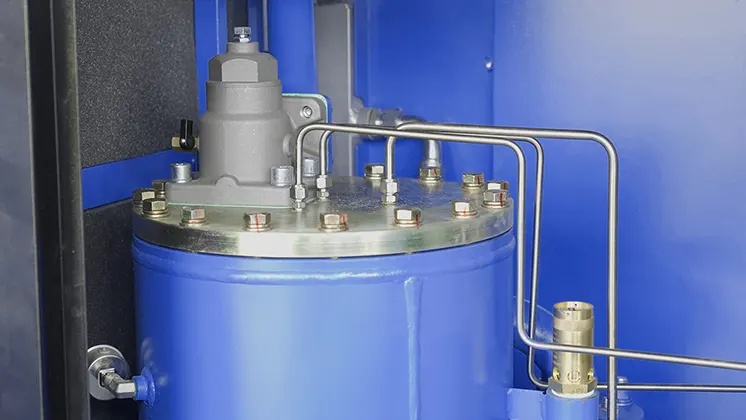

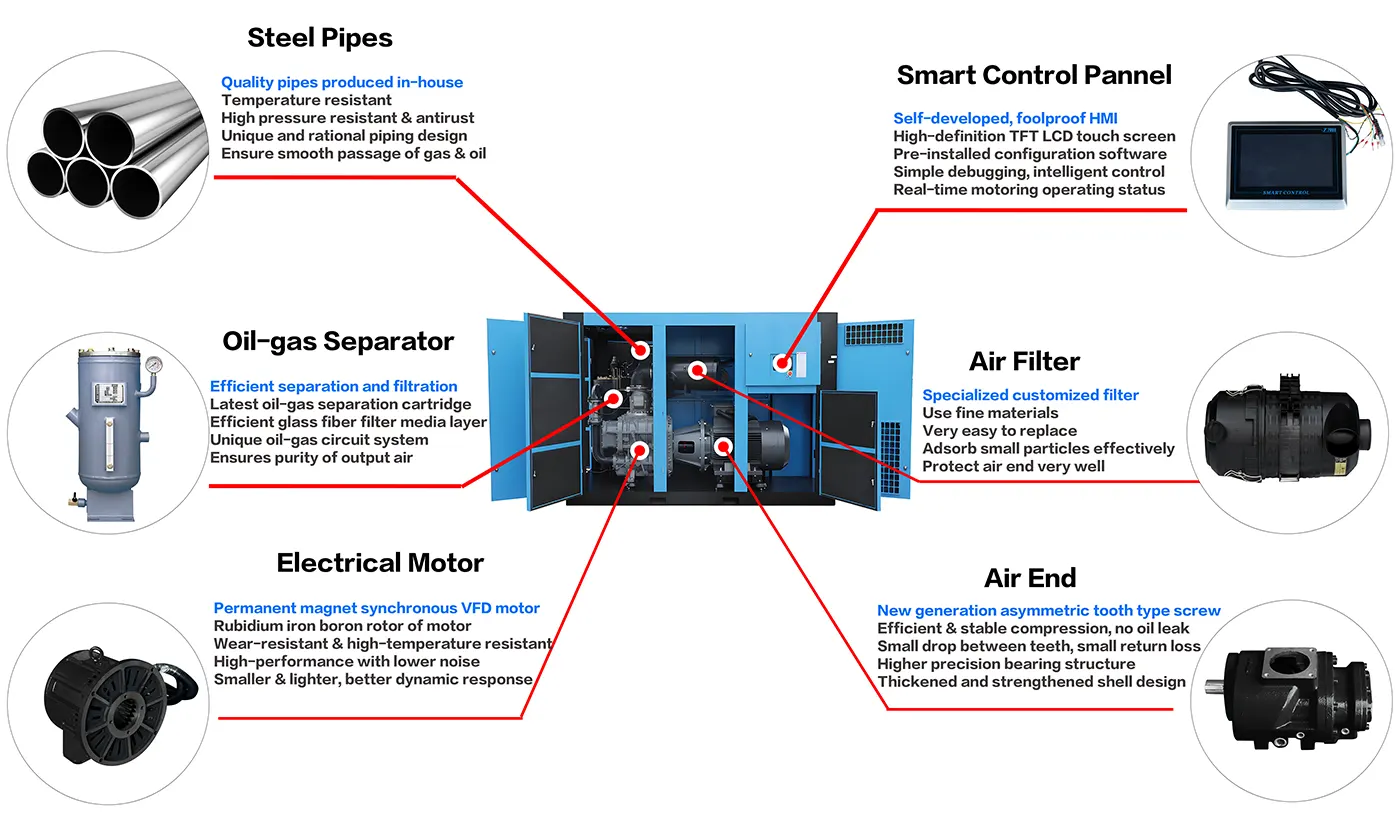

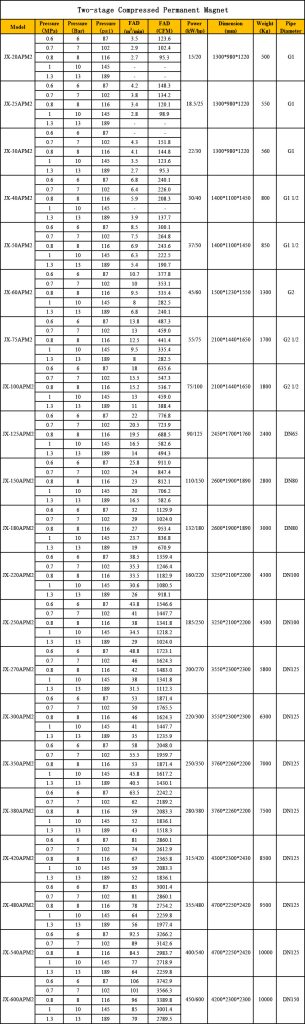

The two-stage 80 Gallon Air Compressor – JX-350APM2 is an industrial series that has the requirement to offer the necessary air pressure as well as volume for jobs that require extra pressure. This powerful unit is suitable for manufacturing industries, automobile repairs, and many constructions repetitively to ensure an adequate supply of compressed air as required. The JX-350APM2 has a powerful structure and technology as the competitive advantage that enhances performance and productivity.

JX-350APM2

- Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

- FAD (m³/min): 58/55.5/53/45.8/40.5

- Power(KW/HP): 250/350

- Weigt(kg): 7000

- Pipe Diameter: DN125

- Dimension(mm): 3760*2260*2200

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-180APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 32/29/27/23.7/19

-

Power(KW/HP): 132/180

-

Weigt(kg): 3000

-

Pipe Diameter: DN80

-

Dimension(mm): 2600*1900*1890

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-220APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 38.5/35.3/33.5/30.6/26

-

Power(KW/HP): 160/220

-

Weigt(kg): 4300

-

Pipe Diameter: DN100

-

Dimension(mm): 3250*2100*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-270APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 48.8/46/42/38/31.5

-

Power(KW/HP): 200/270

-

Weigt(kg): 5800

-

Pipe Diameter: DN125

-

Dimension(mm): 3550*2300*2300

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-380APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 63.5/62/59/52/43

-

Power(KW/HP): 280/380

-

Weigt(kg): 7500

-

Pipe Diameter: DN125

-

Dimension(mm): 3760*2260*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-15AS-11KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

JX-10APML

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

JX-10APMLT

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

Get In Touch