30 Gallon Two Stage Air Compressor

Perfect choice for air solution!

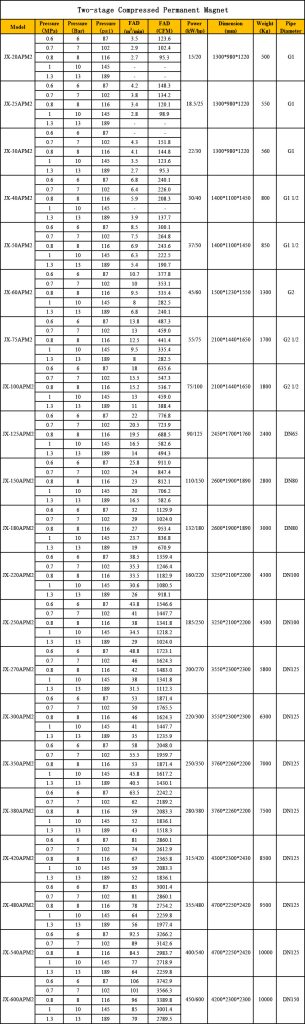

Two Stage Air Compressors

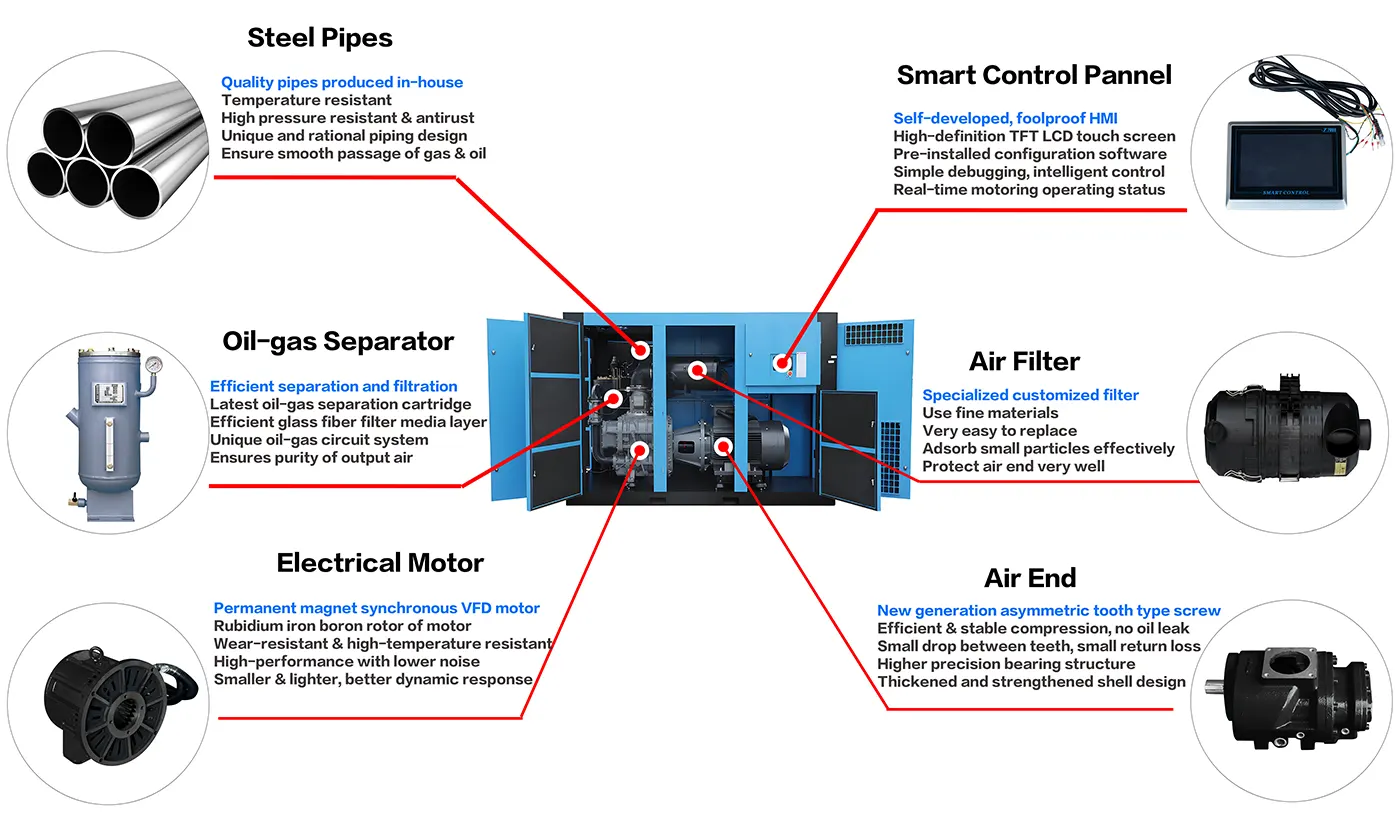

Specification 30 Gallon Two Stage Air Compressor – JX-300APM2 is ideal for industrial applications where quality and durability of air compression is the major difference and pump. There is a variation of this type of compressor that comes with two stages and this makes it more efficient because of the ability to deliver more air and the best one for every work. The JX-300APM2 even has quite a flexible air supply and that means that no matter the job, the power is in your hands.

JX-300APM2

- Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

- FAD (m³/min): 53/50/46/41/35

- Power(KW/HP): 220/300

- Weigt(kg): 6300

- Pipe Diameter: DN125

- Dimension(mm): 3550*2300*2300

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-180APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 32/29/27/23.7/19

-

Power(KW/HP): 132/180

-

Weigt(kg): 3000

-

Pipe Diameter: DN80

-

Dimension(mm): 2600*1900*1890

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-220APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 38.5/35.3/33.5/30.6/26

-

Power(KW/HP): 160/220

-

Weigt(kg): 4300

-

Pipe Diameter: DN100

-

Dimension(mm): 3250*2100*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-270APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 48.8/46/42/38/31.5

-

Power(KW/HP): 200/270

-

Weigt(kg): 5800

-

Pipe Diameter: DN125

-

Dimension(mm): 3550*2300*2300

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-350APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 58/55.5/53/45.8/40.5

-

Power(KW/HP): 250/350

-

Weigt(kg): 7000

-

Pipe Diameter: DN125

-

Dimension(mm): 3760*2260*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-15AS-11KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

JX-10APML

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

JX-10APMLT

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

Get In Touch