60 Gallon Two Stage Air Compressor

Perfect choice for air solution!

Two Stage Air Compressors

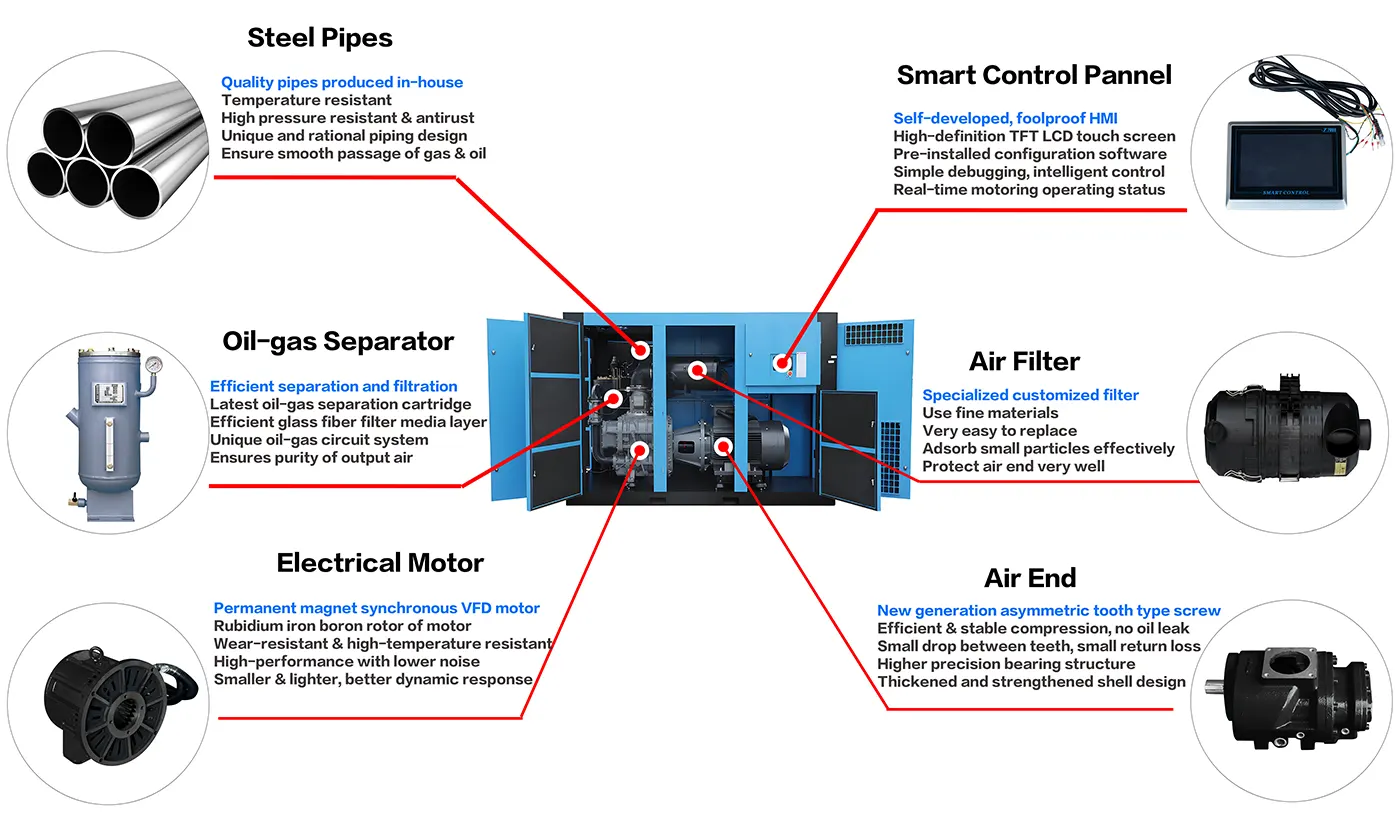

The JX-250APM2 is a 60 Gallon Two Stage Air Compressor, with incredible performance, designed for high-duty operations. This two-stage compressor improves efficiency and high performance, offers high volumes of compressed air, and has the required durability for long-run uses.

JX-250APM2

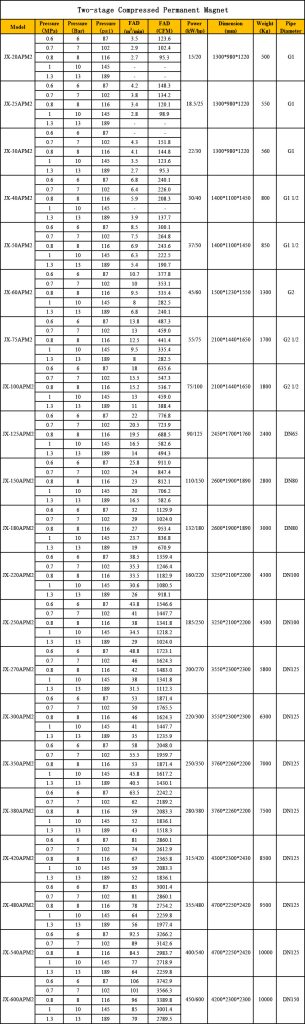

- Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

- FAD (m³/min): 43.8/41/38/34.5/29

- Power(KW/HP): 185/250

- Weigt(kg): 4500

- Pipe Diameter: DN100

- Dimension(mm): 3250*2100*2200

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-100APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 18/15.5/15.2/13/11

-

Power(KW/HP): 75/100

-

Weigt(kg): 1800

-

Pipe Diameter: G2 1/2

-

Dimension(mm): 2100*1440*1650

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-180APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 32/29/27/23.7/19

-

Power(KW/HP): 132/180

-

Weigt(kg): 3000

-

Pipe Diameter: DN80

-

Dimension(mm): 2600*1900*1890

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-270APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 48.8/46/42/38/31.5

-

Power(KW/HP): 200/270

-

Weigt(kg): 5800

-

Pipe Diameter: DN125

-

Dimension(mm): 3550*2300*2300

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-350APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 58/55.5/53/45.8/40.5

-

Power(KW/HP): 250/350

-

Weigt(kg): 7000

-

Pipe Diameter: DN125

-

Dimension(mm): 3760*2260*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-15AS-11KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

JX-10APML

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

JX-10APMLT

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

Get In Touch