Two Stage Air Compressors For Sale

Perfect choice for air solution!

Two Stage Air Compressors

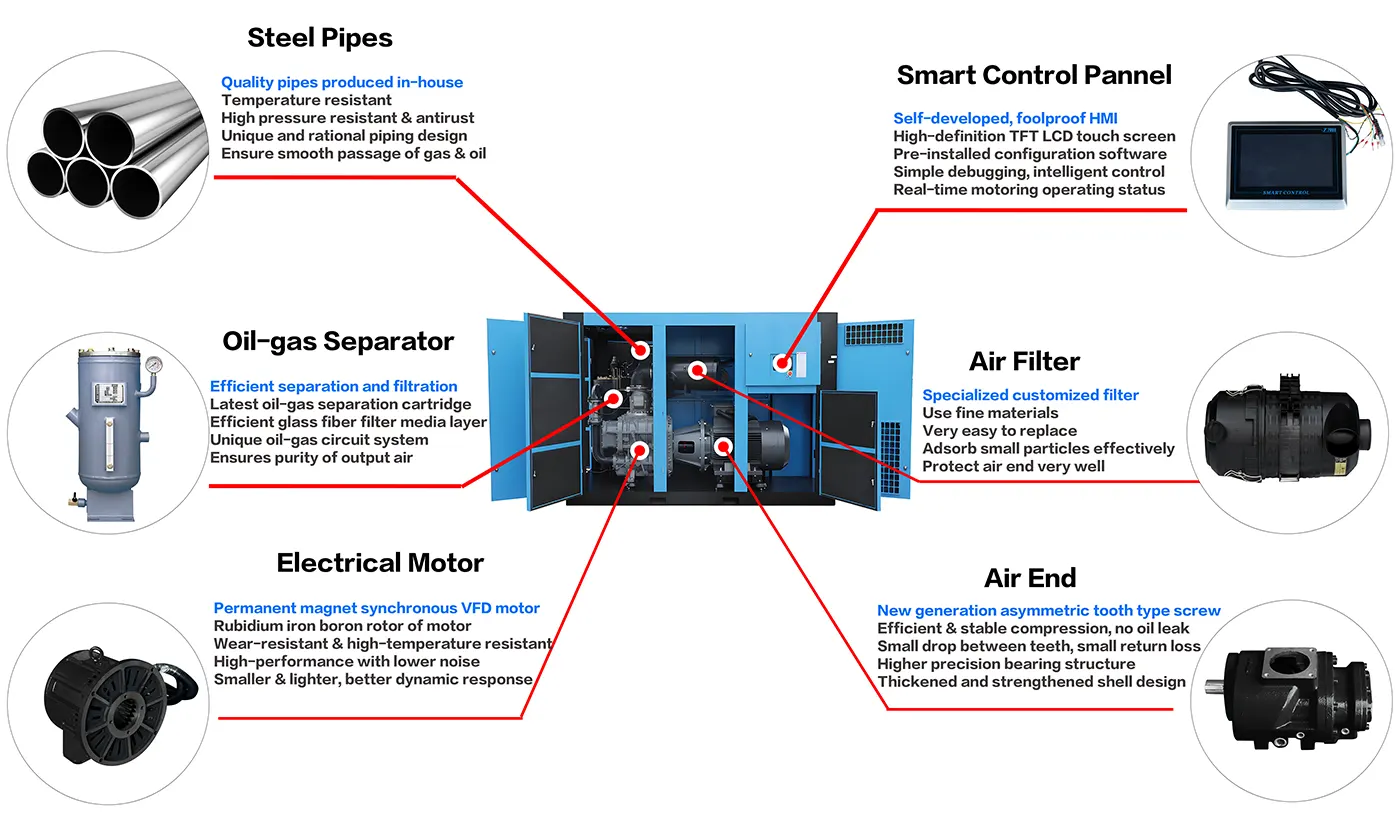

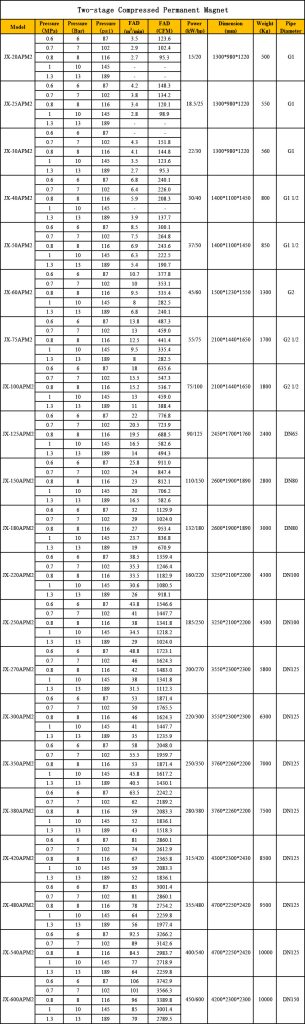

The JX-180APM2 Two Stage Air Compressor is a high-performing product that is capable of meeting many different tasks that can be demanded of it in the industrial sector. This model contains two stages of compression to provide high, stable flow rates for critically demanding applications. The flexibility of the pressure setting makes it ideal for use in light, mid, and heavy industrial applications as well as some specific tasks.

JX-180APM2

- Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

- FAD (m³/min): 32/29/27/23.7/19

- Power(KW/HP): 132/180

- Weigt(kg): 3000

- Pipe Diameter: DN80

- Dimension(mm): 2600*1900*1890

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-100APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 18/15.5/15.2/13/11

-

Power(KW/HP): 75/100

-

Weigt(kg): 1800

-

Pipe Diameter: G2 1/2

-

Dimension(mm): 2100*1440*1650

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-125APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 22/20.5/19.5/16.5/14

-

Power(KW/HP): 90/125

-

Weigt(kg): 2400

-

Pipe Diameter: DN65

-

Dimension(mm): 2450*1700*1760

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-150APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 25.8/24/23/20/16.5

-

Power(KW/HP): 110/150

-

Weigt(kg): 2800

-

Pipe Diameter: DN80

-

Dimension(mm): 2600*1900*1890

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-220APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 38.5/35.3/33.5/30.6/26

-

Power(KW/HP): 160/220

-

Weigt(kg): 4300

-

Pipe Diameter: DN100

-

Dimension(mm): 3250*2100*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-15AS-11KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

JX-10APML

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

JX-10APMLT

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

Get In Touch