Two Stage Air Compressors

Perfect choice for air solution!

Two Stage Air Compressors

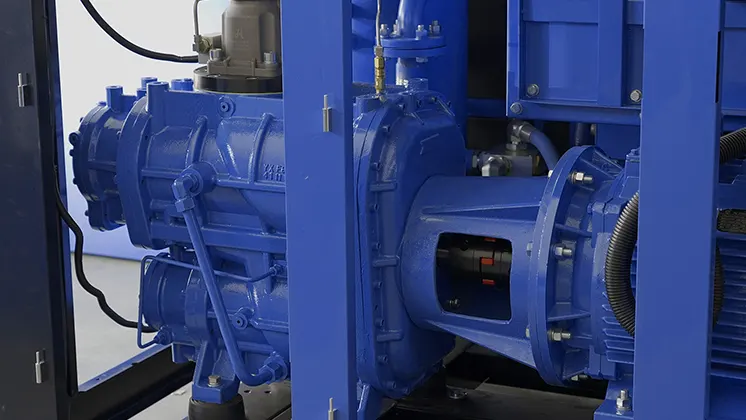

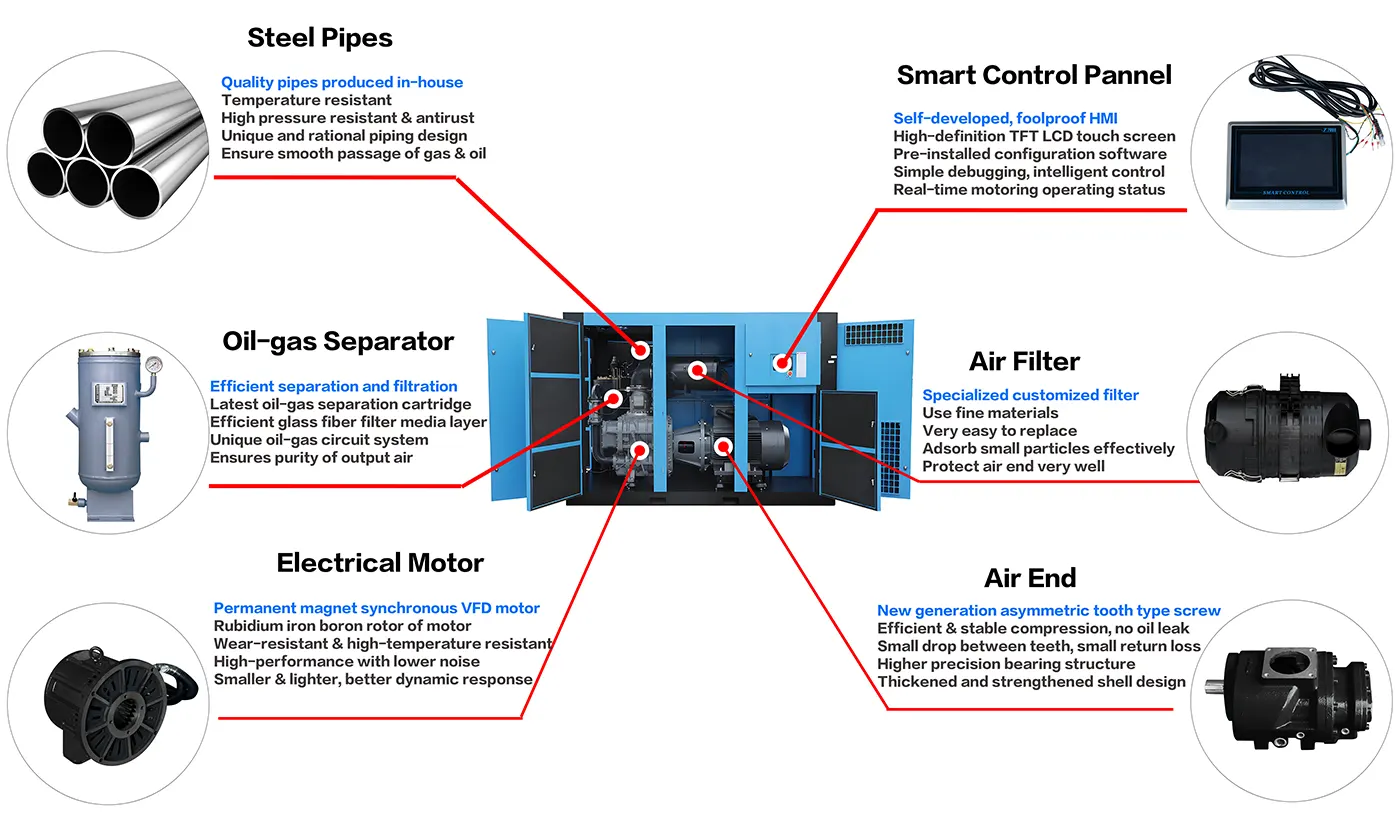

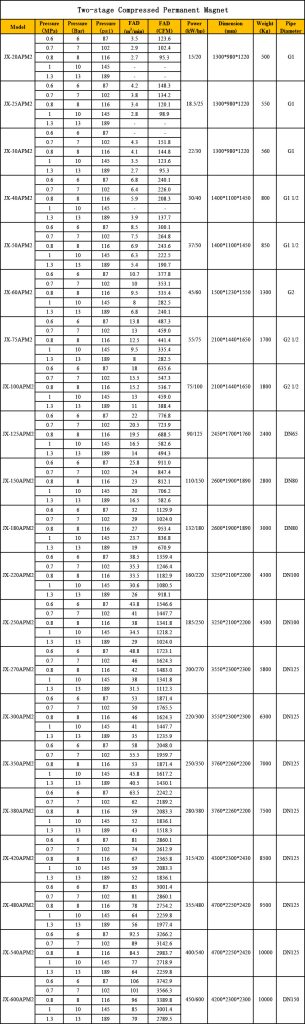

JX-100APM2 Two Stage Air Compressor for industrial uses incredible Industrial performance and strength is assured. Specific to this Air compressor pressures are of the order of 0,6 up to 1,3 MPa(87 up to 189 psi),with a flow capability to 18m³/min(635.6CFM). The JX-100APM2 model is even more enhanced using a 75 kW ( 100 HP) in order to ensure that with operation, the machine does not stop. The kind of model which is developed is usually equipped with attributes that enable them to be utilized in their best hence can probably operate under unfavorable environment like the factories, workshops, construction areas, etc.

JX-100APM2

- Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

- FAD (m³/min): 18/15.5/15.2/13/11

- Power(KW/HP): 75/100

- Weigt(kg): 1800

- Pipe Diameter: G2 1/2

- Dimension(mm): 2100*1440*1650

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-20APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 3.5/2.9/2.7

-

Power(KW/HP): 15/20

-

Weigt(kg): 500

-

Pipe Diameter: G1

-

Dimension(mm): 1300*980*1220

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-125APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 22/20.5/19.5/16.5/14

-

Power(KW/HP): 90/125

-

Weigt(kg): 2400

-

Pipe Diameter: DN65

-

Dimension(mm): 2450*1700*1760

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-150APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 25.8/24/23/20/16.5

-

Power(KW/HP): 110/150

-

Weigt(kg): 2800

-

Pipe Diameter: DN80

-

Dimension(mm): 2600*1900*1890

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-180APM2

-

Pressure(MPa): 0.6/0.7/0.8/1.0/1.3

-

FAD (m³/min): 32/29/27/23.7/19

-

Power(KW/HP): 132/180

-

Weigt(kg): 3000

-

Pipe Diameter: DN80

-

Dimension(mm): 2600*1900*1890

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-15AS-11KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

JX-10APML

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

JX-10APMLT

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

Get In Touch