Best Oil Free Air Compressors

Air compressors that can help companies solve their problems.

Oil Free Air Compressor

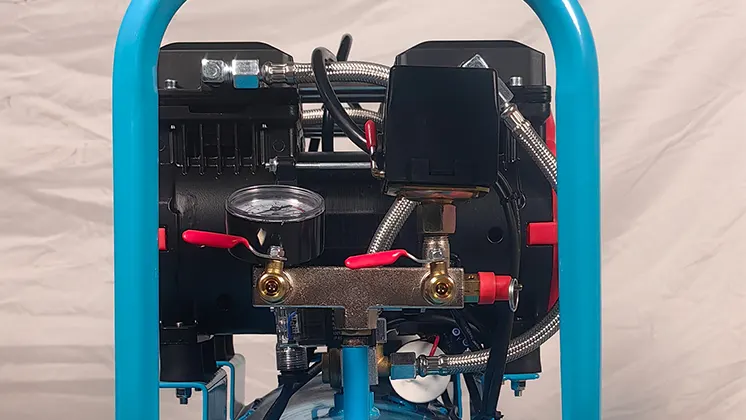

The VP-8002-50 Best Oil-Free Air Compressor is currently one of the most effective, small, and consistent solutions to go with applications that necessitate clean, oilless compressed air. Suitable for small industrial, automotive, or DIY applications, this model is_iso lear with low noise and low maintenance, especially for those areas where air quality is an essential factor. Its small form factor and the direct drive system make it simple to use, and the motor offers durability.

VP-8002-50

- Pressure(MPa): 0.8

- FAD(m³/min): 0.2

- Power(KW/HP): 1.6

- Air Receiver(L): 50

- Dimension(mm): 680*330*670

- Weigt(kg): 41

- Pipe Diameter: G1/4

- Power Supply: 220V/50Hz

- Drive Mode: Direct Drive

- Startup Mode: Industrial Frequency Startup

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

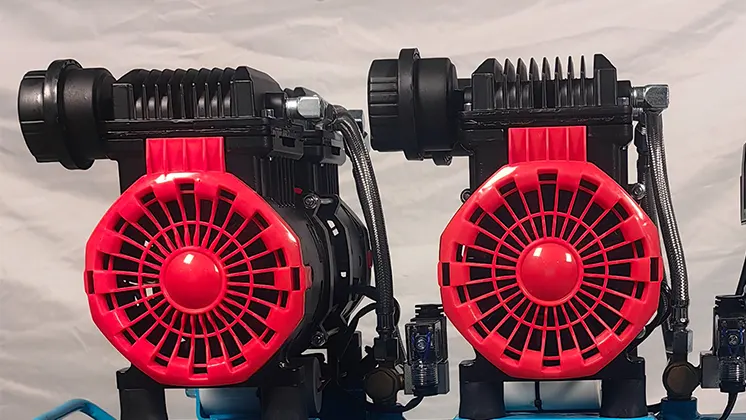

VP-14903-100

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.45

-

Power(KW/HP): 4.47

-

Air Receiver(L): 100

-

Dimension(mm): 1070*350*750

-

Weigt(kg): 68

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-14904-120

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.6

-

Power(KW/HP): 5.96

-

Air Receiver(L): 120

-

Dimension(mm): 1300*400*760

-

Weigt(kg): 90

-

Pipe Diameter: G1/4, G1/2

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

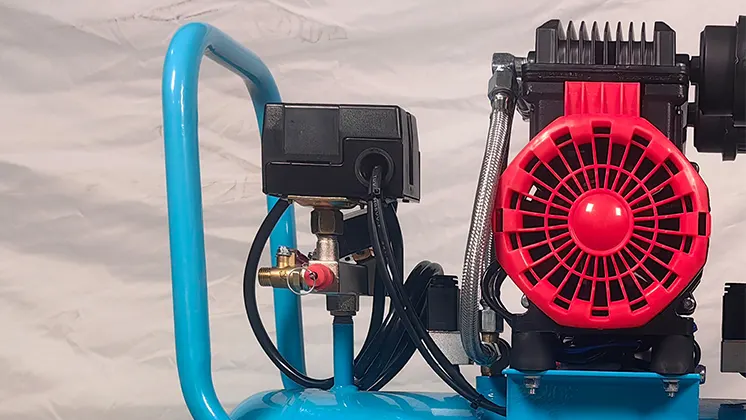

VP-6002-50

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.16

-

Power(KW/HP): 1.2

-

Air Receiver(L): 50

-

Dimension(mm): 680*330*670

-

Weigt(kg): 38

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-6003-80

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.24

-

Power(KW/HP): 1.8

-

Air Receiver(L): 80

-

Dimension(mm): 960*370*760

-

Weigt(kg): 57

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

You May Also Like

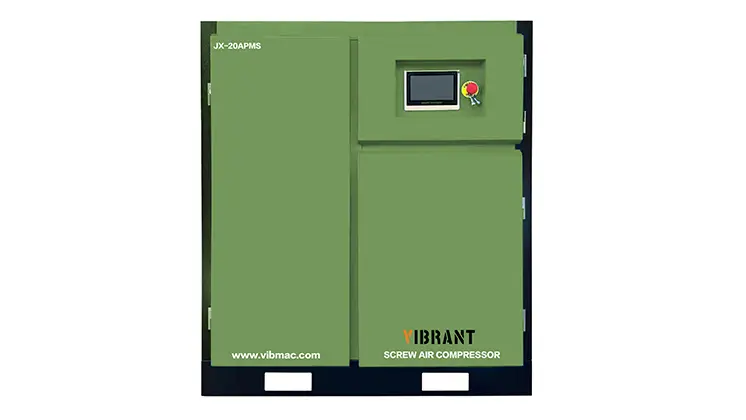

JX-20APMS-20HP/15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.3~1.7

-

Power(KW/HP): 15/20

VIEW MORE

JX-20APMX-15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.4~1.8

-

Power(KW/HP): 15/20

VIEW MORE

JX-20AS-15KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

VIEW MORE

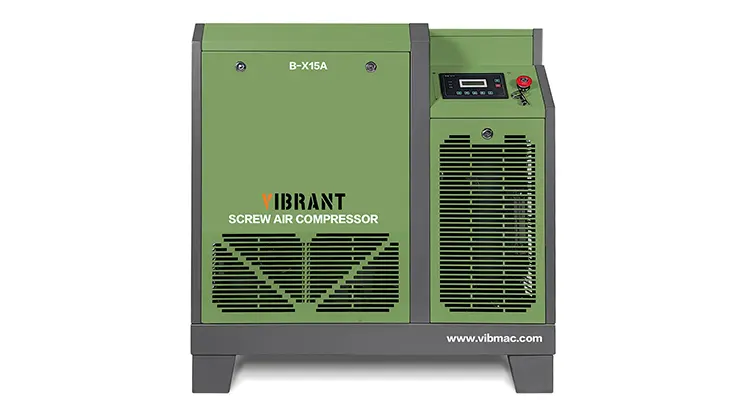

B-X15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

VIEW MORE

Get In Touch