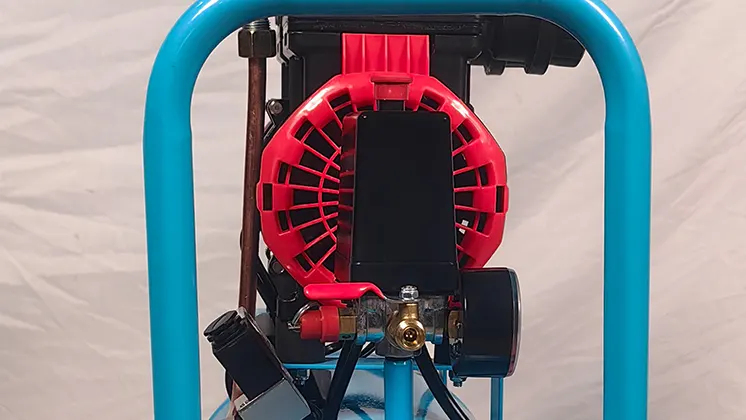

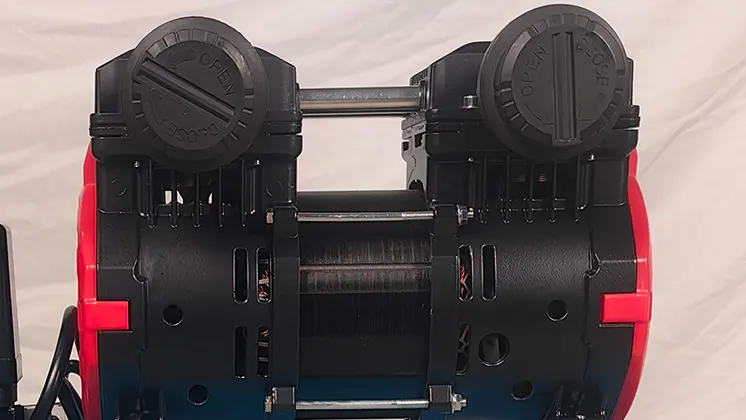

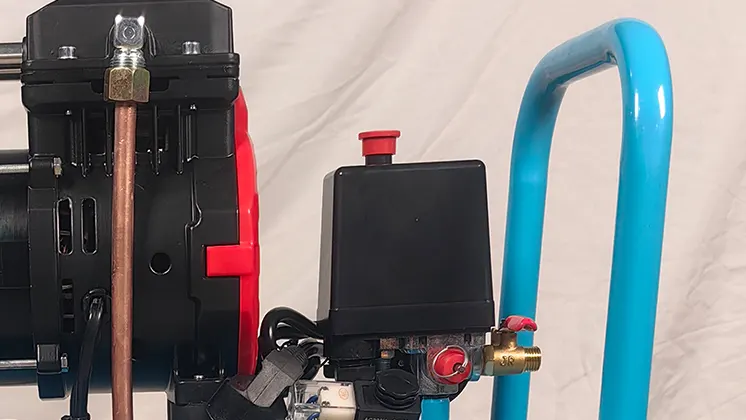

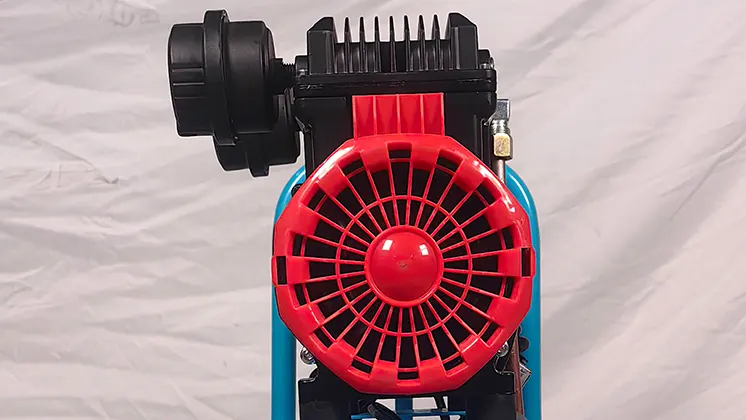

60 Gallon Oil Free Air Compressor

Air compressors that can help companies solve their problems.

Oil Free Air Compressor

The 60 Gallon Oil-Free Air Compressor – VP-8001-30 is therefore an efficient and portable air compressor for light industrial usage in applications that need clean and oil-free compressed air. Originally developed for small-scale workshops, home-based garages, or even for those adopting small-scale pneumatic operations it is a compact machine that is reliable and easy to operate with minimum maintenance requirements.

VP-8001-30

- Pressure(MPa): 0.8

- FAD(m³/min): 0.1

- Power(KW/HP): 0.8

- Air Receiver(L): 30

- Dimension(mm): 620*270*570

- Weigt(kg): 22

- Pipe Diameter: G1/4

- Power Supply: 220V/50Hz

- Drive Mode: Direct Drive

- Startup Mode: Industrial Frequency Startup

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

VP-8002-50

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.2

-

Power(KW/HP): 1.6

-

Air Receiver(L): 50

-

Dimension(mm): 680*330*670

-

Weigt(kg): 41

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-8003-80

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.3

-

Power(KW/HP): 2.4

-

Air Receiver(L): 80

-

Dimension(mm): 960*370*760

-

Weigt(kg): 62

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-6002-50

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.16

-

Power(KW/HP): 1.2

-

Air Receiver(L): 50

-

Dimension(mm): 680*330*670

-

Weigt(kg): 38

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-6003-80

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.24

-

Power(KW/HP): 1.8

-

Air Receiver(L): 80

-

Dimension(mm): 960*370*760

-

Weigt(kg): 57

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

You May Also Like

JX-20APMS-20HP/15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.3~1.7

-

Power(KW/HP): 15/20

VIEW MORE

JX-20APMX-15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.4~1.8

-

Power(KW/HP): 15/20

VIEW MORE

JX-20AS-15KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

VIEW MORE

B-X15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

VIEW MORE

Get In Touch