1 Hp Oil Free Air Compressor

Air compressors that can help companies solve their problems.

Oil Free Air Compressor

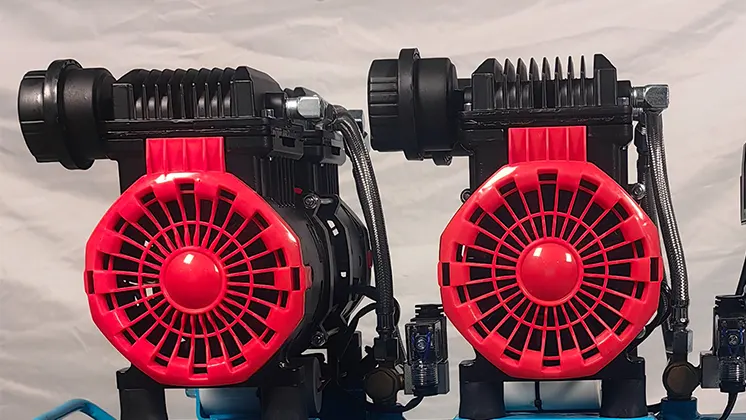

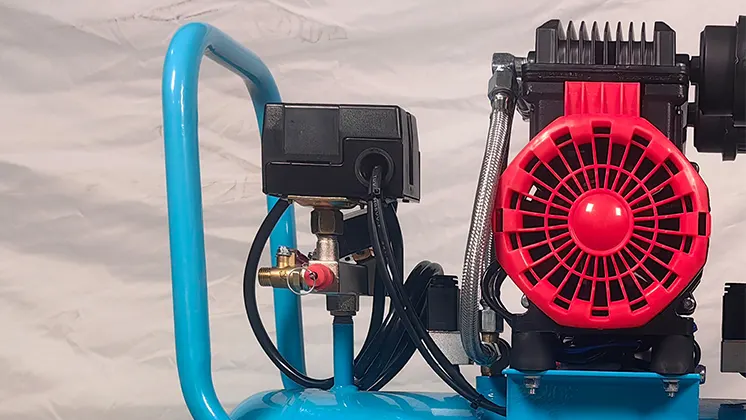

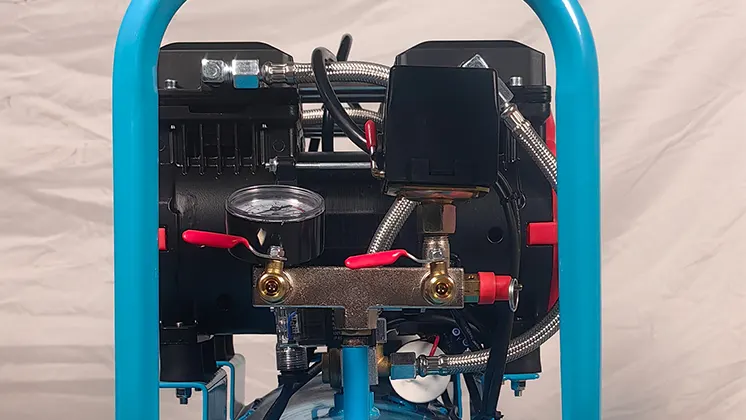

Due to its small size the 1 HP Oil-Free Air Compressor – VP-6002-50 is suitable for shop use where clean oil-free compressed air is required. It comes without oil to produce clean air needed for particular exercises like using air tools and inflating bicycles among other exercises that may require conserved air. The VP-6002-50 is ideal for home workshop use, minor automobile requirements, and Do-It-Yourself projects due to noise, dimension, portability, and simplicity of use.

VP-6002-50

- Pressure(MPa): 0.8

- FAD(m³/min): 0.16

- Power(KW/HP): 1.2

- Air Receiver(L): 50

- Dimension(mm): 680*330*670

- Weigt(kg): 38

- Pipe Diameter: G1/4

- Power Supply: 220V/50Hz

- Drive Mode: Direct Drive

- Startup Mode: Industrial Frequency Startup

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

VP-14903-100

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.45

-

Power(KW/HP): 4.47

-

Air Receiver(L): 100

-

Dimension(mm): 1070*350*750

-

Weigt(kg): 68

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-6001-30

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.08

-

Power(KW/HP): 0.6

-

Air Receiver(L): 30

-

Dimension(mm): 620*270*570

-

Weigt(kg): 21

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

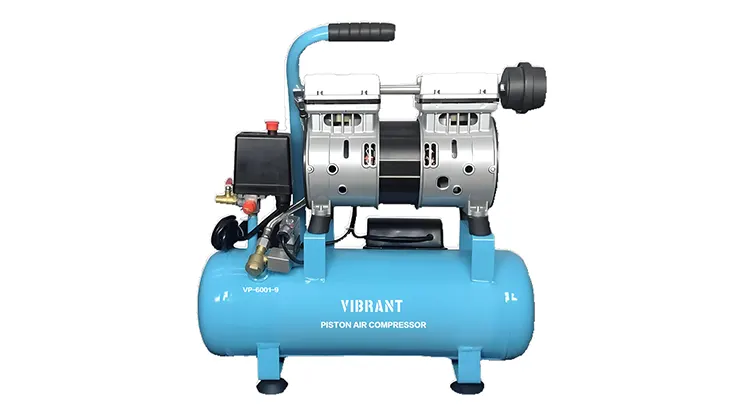

VP-6001-9

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.08

-

Power(KW/HP): 0.6

-

Air Receiver(L): 9

-

Dimension(mm): 500*220*520

-

Weigt(kg): 16

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-6003-80

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.24

-

Power(KW/HP): 1.8

-

Air Receiver(L): 80

-

Dimension(mm): 960*370*760

-

Weigt(kg): 57

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

You May Also Like

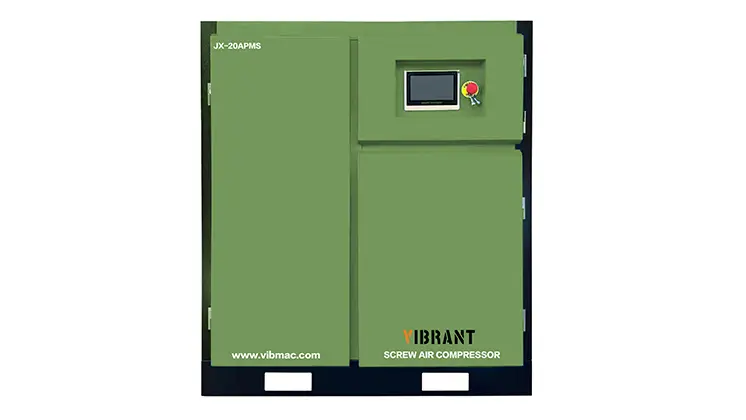

JX-20APMS-20HP/15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.3~1.7

-

Power(KW/HP): 15/20

VIEW MORE

JX-20APMX-15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.4~1.8

-

Power(KW/HP): 15/20

VIEW MORE

JX-20AS-15KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

VIEW MORE

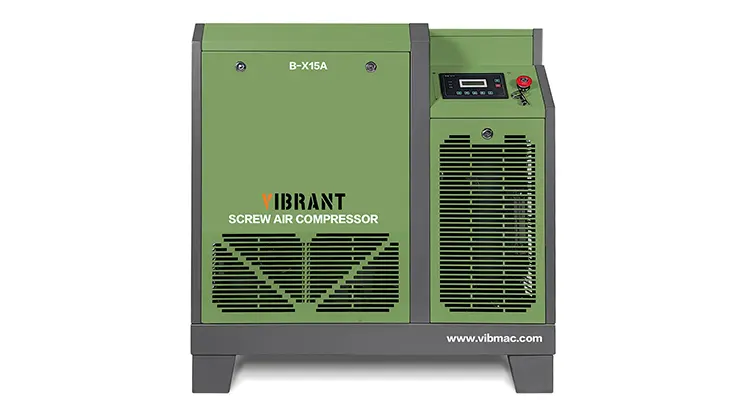

B-X15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

VIEW MORE

Get In Touch