Oil Free Screw Air Compressor

Air compressors that can help companies solve their problems.

Oil Free Air Compressor

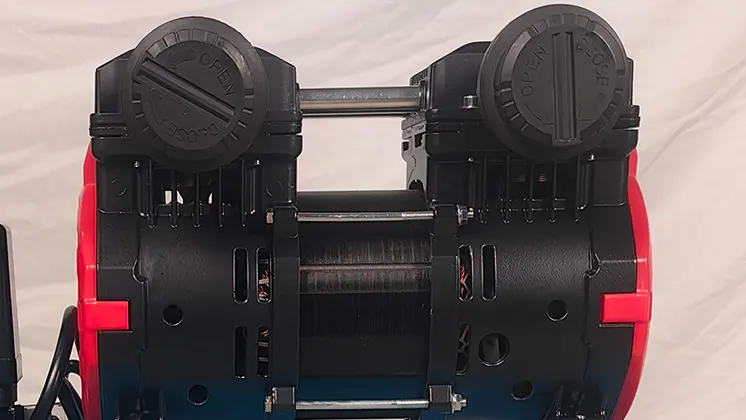

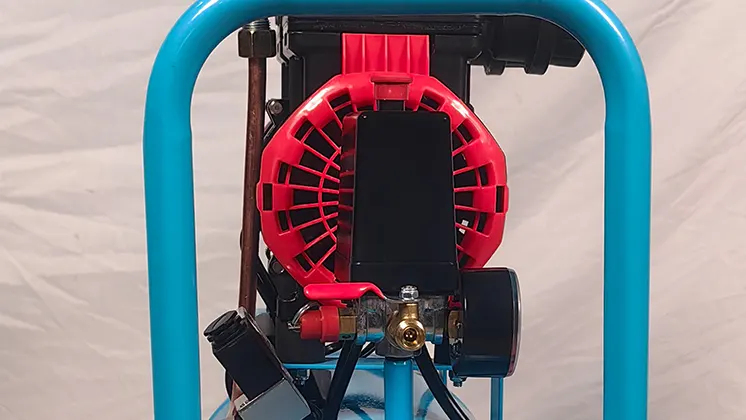

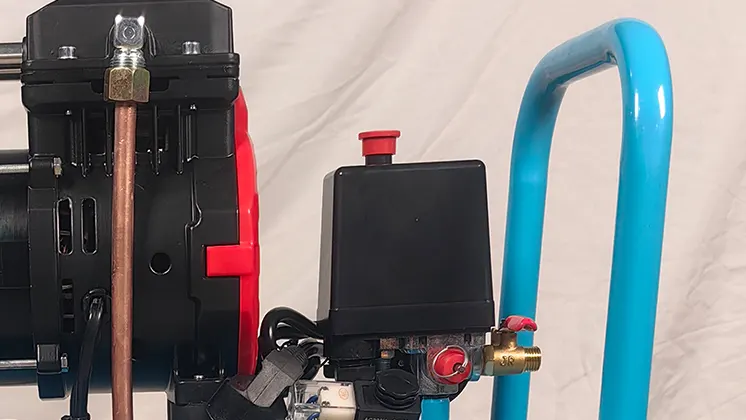

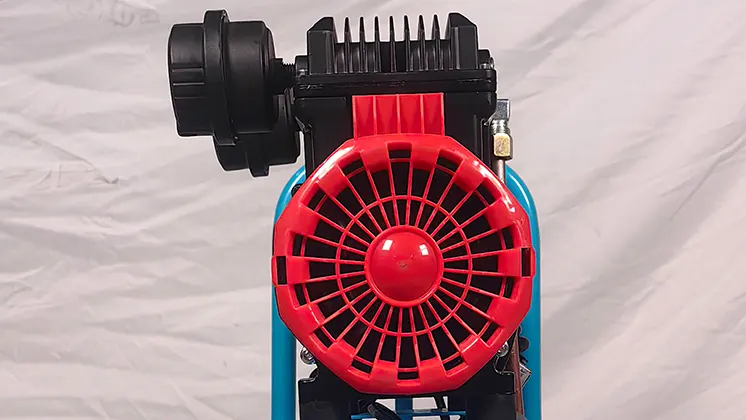

Oil-Free Screw Air Compressor fully named, VP-6001-30, is a compressor that can provide highly compressed air with no admixture of oil specially for applications that are very sensitive to the presence of airborne particles of oil. It has no oil containment feature in its screw, thus making it ideal for use in industries such as; food, pharmacy, electronics, and laboratory. It is a direct drive system with small dimensions, is optimally suitable for spaces where equipment’s installation is a concern but does not compromise on the performance level of the device.

VP-6001-30

- Pressure(MPa): 0.8

- FAD(m³/min): 0.08

- Power(KW/HP): 0.6

- Air Receiver(L): 30

- Dimension(mm): 620*270*570

- Weigt(kg): 21

- Pipe Diameter: G1/4

- Power Supply: 220V/50Hz

- Drive Mode: Direct Drive

- Startup Mode: Industrial Frequency Startup

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

VP-14901-30

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.15

-

Power(KW/HP): 1.49

-

Air Receiver(L): 30

-

Dimension(mm): 620*270*570

-

Weigt(kg): 22.5

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

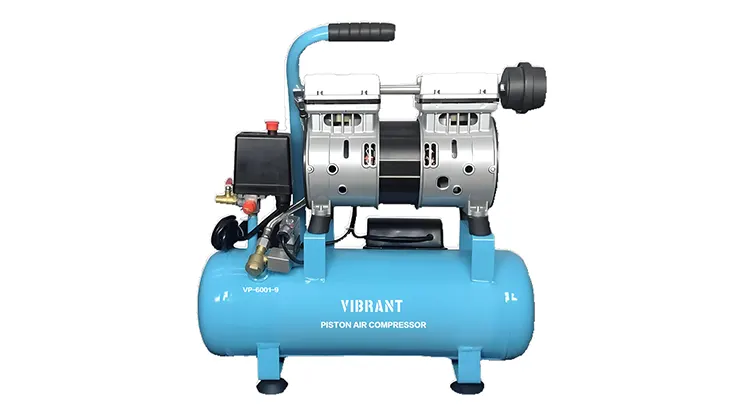

VP-6001-9

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.08

-

Power(KW/HP): 0.6

-

Air Receiver(L): 9

-

Dimension(mm): 500*220*520

-

Weigt(kg): 16

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-8001-30

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.1

-

Power(KW/HP): 0.8

-

Air Receiver(L): 30

-

Dimension(mm): 620*270*570

-

Weigt(kg): 22

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-14902-50

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.3

-

Power(KW/HP): 2.98

-

Air Receiver(L): 50

-

Dimension(mm): 680*330*670

-

Weigt(kg): 42

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

You May Also Like

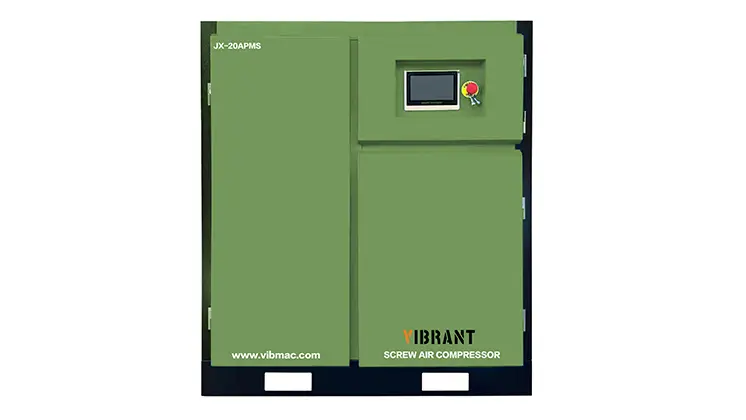

JX-20APMS-20HP/15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.3~1.7

-

Power(KW/HP): 15/20

VIEW MORE

JX-20APMX-15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.4~1.8

-

Power(KW/HP): 15/20

VIEW MORE

JX-20AS-15KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

VIEW MORE

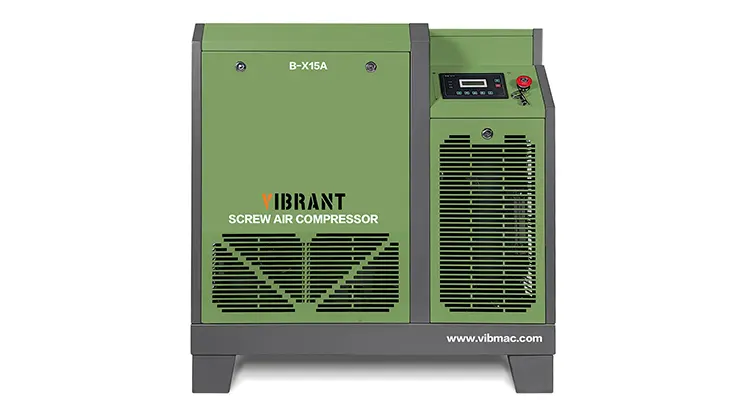

B-X15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

VIEW MORE

Get In Touch