Oil-Free Air Compressor

Air compressors that can help companies solve their problems.

Oil Free Air Compressor

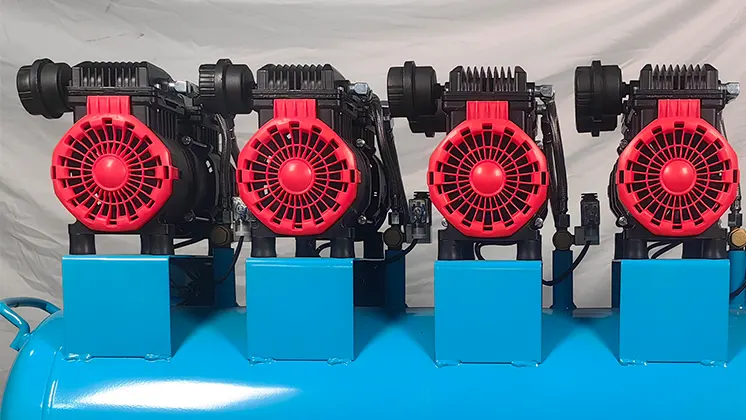

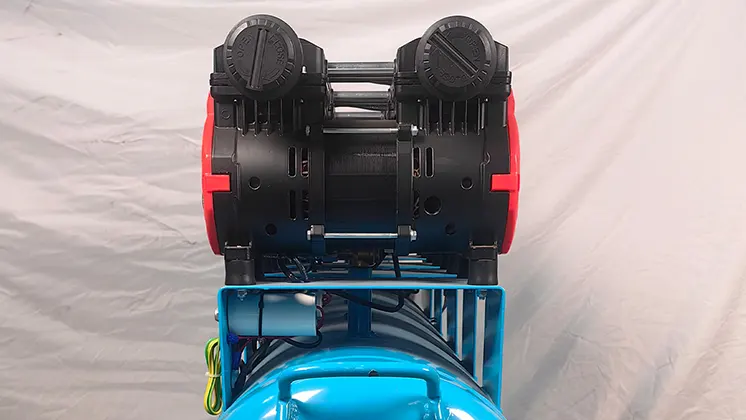

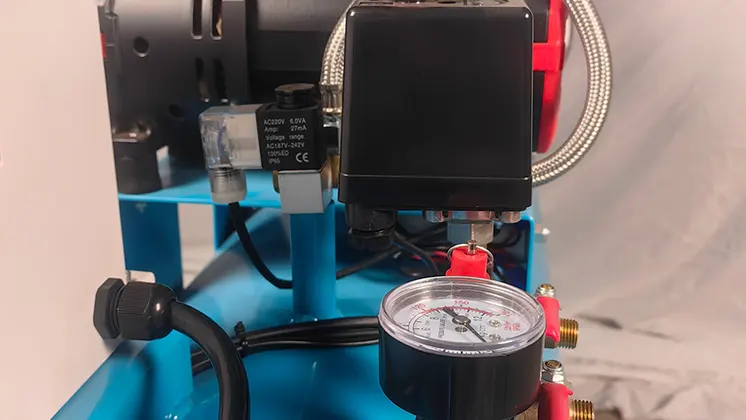

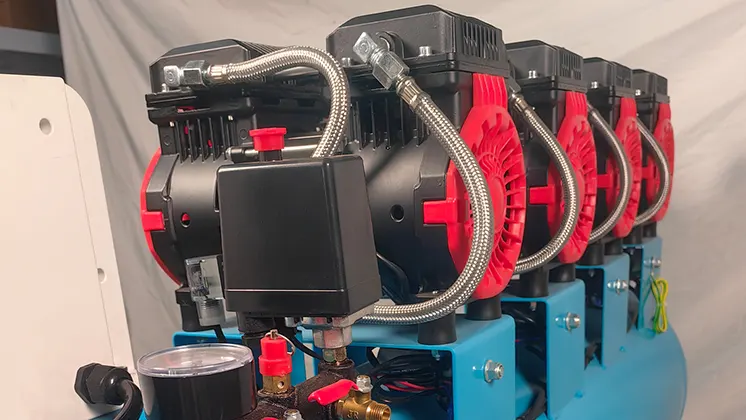

The Oil Free Air Compressor VP-1504-180 Compressor is a high-quality, Heavy-duty air compressor for industrial and commercial purposes without any oil contamination. Some of the features include the lack of oil to be found in the line of products making them ideal for areas such as foods and pharmaceutical, electronics industries, and the like. Direct drive systems improve reliability and reduce the need for maintenance as well as the large 180-litre air receiver ensures adequate air supply for a task that requires it.

VP-1504-180

- Pressure(MPa): 0.8

- FAD(m³/min): 0.8

- Power(KW/HP): 6

- Air Receiver(L): 180

- Dimension(mm): 1550*450*950

- Weigt(kg): 145

- Pipe Diameter: G1/4, G1/2

- Power Supply: 220V/380V 50Hz

- Drive Mode: Direct Drive

- Startup Mode: Industrial Frequency Startup

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

VP-14904-120

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.6

-

Power(KW/HP): 5.96

-

Air Receiver(L): 120

-

Dimension(mm): 1300*400*760

-

Weigt(kg): 90

-

Pipe Diameter: G1/4, G1/2

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-1503-160

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.6

-

Power(KW/HP): 4.5

-

Air Receiver(L): 160

-

Dimension(mm): 1360*450*950

-

Weigt(kg): 115

-

Pipe Diameter: G1/4, G1/2

-

Power Supply: 220V/380V 50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-1504-180

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.8

-

Power(KW/HP): 6

-

Air Receiver(L): 180

-

Dimension(mm): 1550*450*950

-

Weigt(kg): 145

-

Pipe Diameter: G1/4, G1/2

-

Power Supply: 220V/380V 50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-6004-120

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.32

-

Power(KW/HP): 2.4

-

Air Receiver(L): 120

-

Dimension(mm): 1300*400*760

-

Weigt(kg): 90

-

Pipe Diameter: G1/4, G1/2

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

You May Also Like

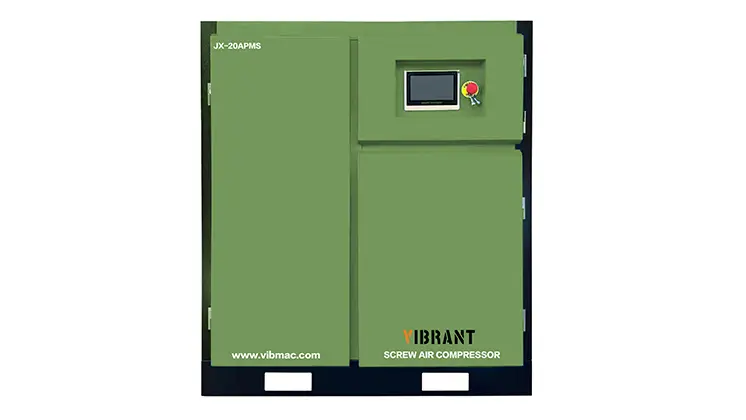

JX-20APMS-20HP/15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.3~1.7

-

Power(KW/HP): 15/20

VIEW MORE

JX-20APMX-15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.4~1.8

-

Power(KW/HP): 15/20

VIEW MORE

JX-20AS-15KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

VIEW MORE

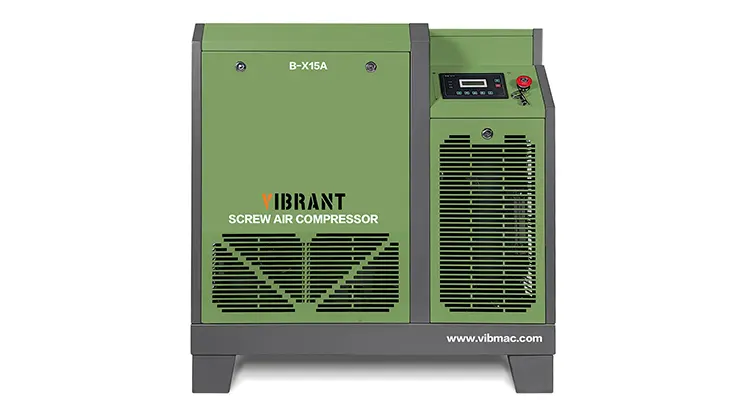

B-X15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

VIEW MORE

Get In Touch