Oil Or Oil Free Air Compressor

Air compressors that can help companies solve their problems.

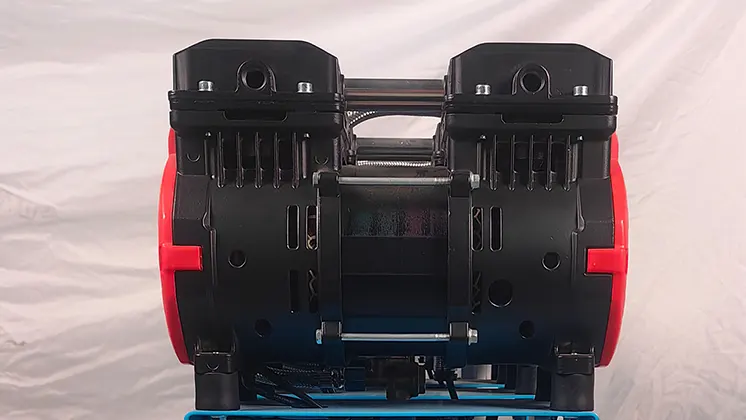

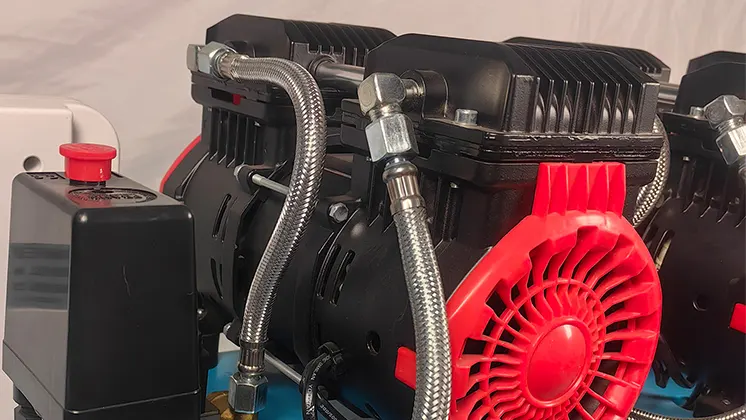

Oil Free Air Compressor

The Oil or Oil-Free Air Compressor – VP-1503-160 is yet another industrial and commercial-grade air compressor among the products. For those applications that cannot tolerate even a trace of oil, this compressor can easily be converted from the conventional oil-lubricated compressor to an oil-free one. With a 160 liters air receiver and 4.5kw (6 Hp) motor it is used for medium to high-demand applications hence providing reliable and uninterrupted compressed air.

VP-1503-160

- Pressure(MPa): 0.8

- FAD(m³/min): 0.6

- Power(KW/HP): 4.5

- Air Receiver(L): 160

- Dimension(mm): 1360*450*950

- Weigt(kg): 115

- Pipe Diameter: G1/4, G1/2

- Power Supply: 220V/380V 50Hz

- Drive Mode: Direct Drive

- Startup Mode: Industrial Frequency Startup

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

VP-14904-120

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.6

-

Power(KW/HP): 5.96

-

Air Receiver(L): 120

-

Dimension(mm): 1300*400*760

-

Weigt(kg): 90

-

Pipe Diameter: G1/4, G1/2

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-1503-160

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.6

-

Power(KW/HP): 4.5

-

Air Receiver(L): 160

-

Dimension(mm): 1360*450*950

-

Weigt(kg): 115

-

Pipe Diameter: G1/4, G1/2

-

Power Supply: 220V/380V 50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-1504-180

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.8

-

Power(KW/HP): 6

-

Air Receiver(L): 180

-

Dimension(mm): 1550*450*950

-

Weigt(kg): 145

-

Pipe Diameter: G1/4, G1/2

-

Power Supply: 220V/380V 50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-8004-120

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.4

-

Power(KW/HP): 3.2

-

Air Receiver(L): 120

-

Dimension(mm): 1300*400*760

-

Weigt(kg): 92

-

Pipe Diameter: G1/4, G1/2

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

You May Also Like

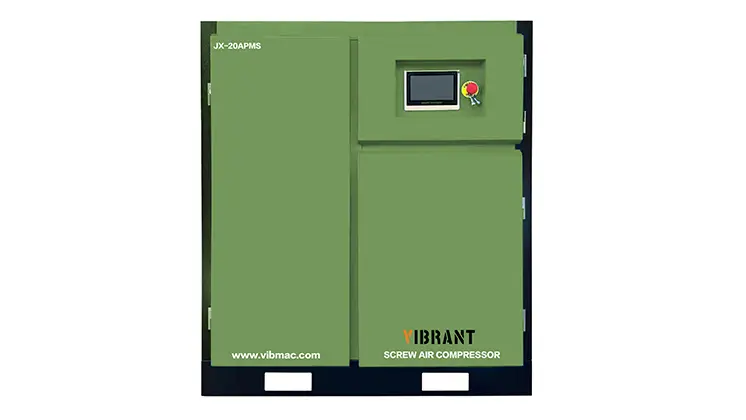

JX-20APMS-20HP/15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.3~1.7

-

Power(KW/HP): 15/20

VIEW MORE

JX-20APMX-15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.4~1.8

-

Power(KW/HP): 15/20

VIEW MORE

JX-20AS-15KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

VIEW MORE

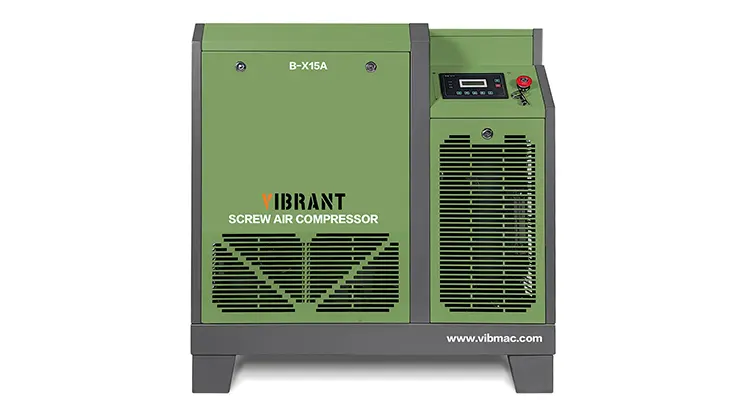

B-X15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

VIEW MORE

Get In Touch