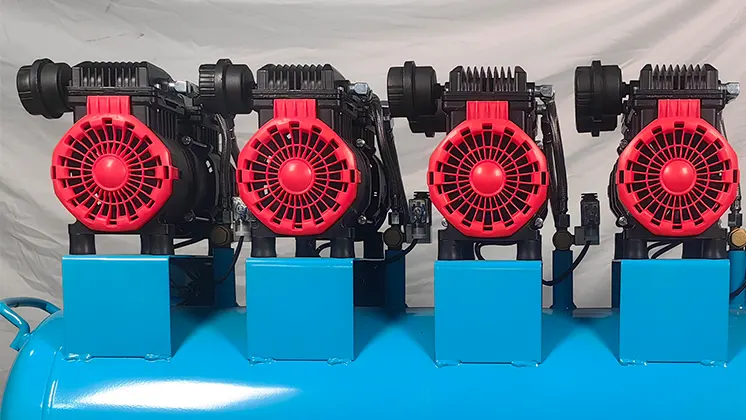

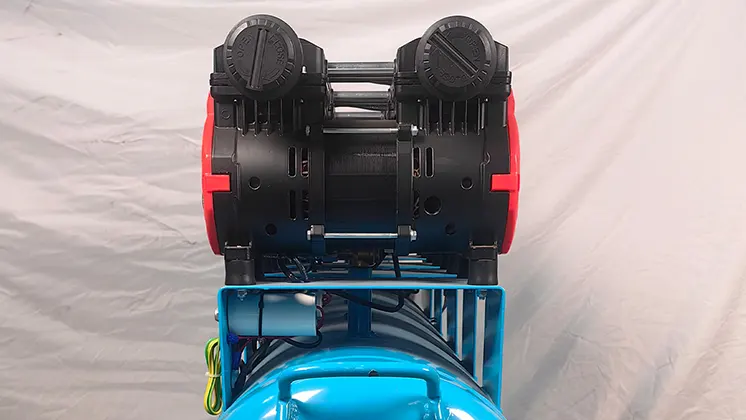

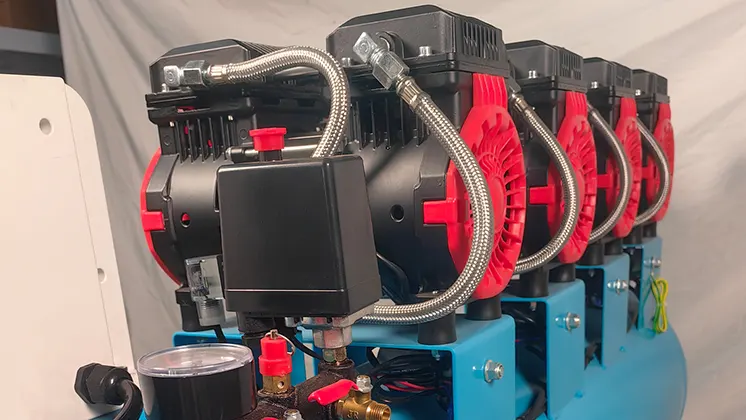

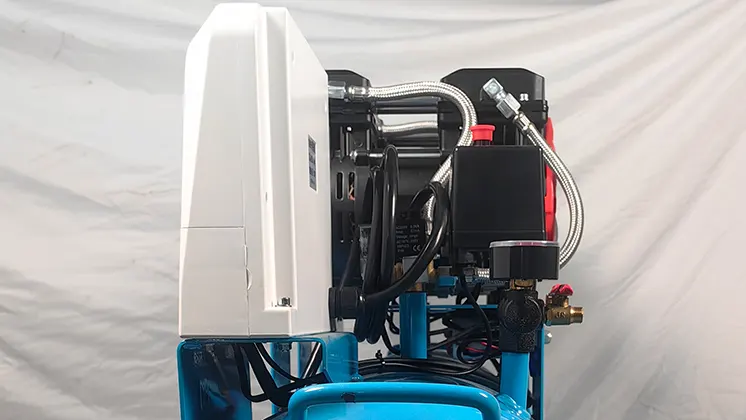

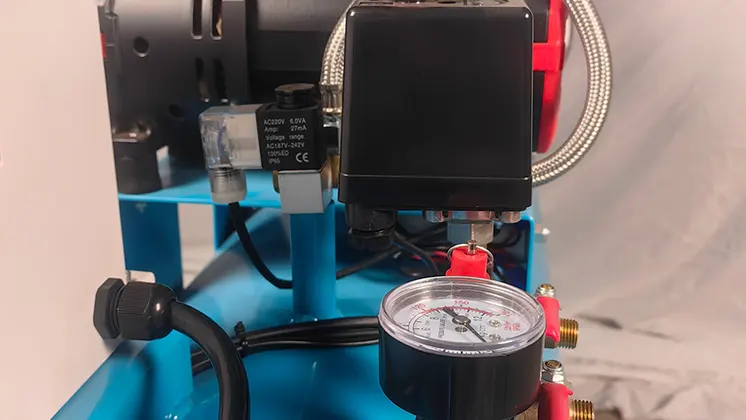

30 Gallon Oil Free Air Compressor

Air compressors that can help companies solve their problems.

Oil Free Air Compressor

The VP-8004-120 30 Gallon Oil-Free Air Compressor is portable and perfect for use in industries where the air needs to be compressed free from oil. With a tank capacity of a 120-litre air receiver and a 3.2 kW motor, this compressor is suited for light industrial and compact working applications. Equipped with a Direct Drive mechanism and Industrial Frequency startup the VP-8004-120 has an FAD of 0.4 m³/minute @ 0.8 MPa pressure. With a size of 1300mm x 400mm x 760mm, this equipment can be easily installed in different workplaces.

VP-8004-120

- Pressure(MPa): 0.8

- FAD(m³/min): 0.4

- Power(KW/HP): 3.2

- Air Receiver(L): 120

- Dimension(mm): 1300*400*760

- Weigt(kg): 92

- Pipe Diameter: G1/4, G1/2

- Power Supply: 220V/50Hz

- Drive Mode: Direct Drive

- Startup Mode: Industrial Frequency Startup

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

VP-14904-120

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.6

-

Power(KW/HP): 5.96

-

Air Receiver(L): 120

-

Dimension(mm): 1300*400*760

-

Weigt(kg): 90

-

Pipe Diameter: G1/4, G1/2

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-1503-160

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.6

-

Power(KW/HP): 4.5

-

Air Receiver(L): 160

-

Dimension(mm): 1360*450*950

-

Weigt(kg): 115

-

Pipe Diameter: G1/4, G1/2

-

Power Supply: 220V/380V 50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-1504-180

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.8

-

Power(KW/HP): 6

-

Air Receiver(L): 180

-

Dimension(mm): 1550*450*950

-

Weigt(kg): 145

-

Pipe Diameter: G1/4, G1/2

-

Power Supply: 220V/380V 50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-8004-120

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.4

-

Power(KW/HP): 3.2

-

Air Receiver(L): 120

-

Dimension(mm): 1300*400*760

-

Weigt(kg): 92

-

Pipe Diameter: G1/4, G1/2

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

You May Also Like

JX-20APMS-20HP/15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.3~1.7

-

Power(KW/HP): 15/20

VIEW MORE

JX-20APMX-15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.4~1.8

-

Power(KW/HP): 15/20

VIEW MORE

JX-20AS-15KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

VIEW MORE

B-X15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

VIEW MORE

Get In Touch