Air Compressor Oil Free

Air compressors that can help companies solve their problems.

Oil Free Air Compressor

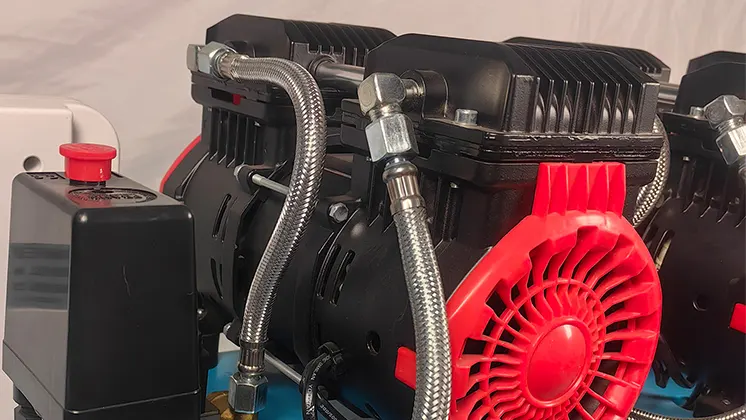

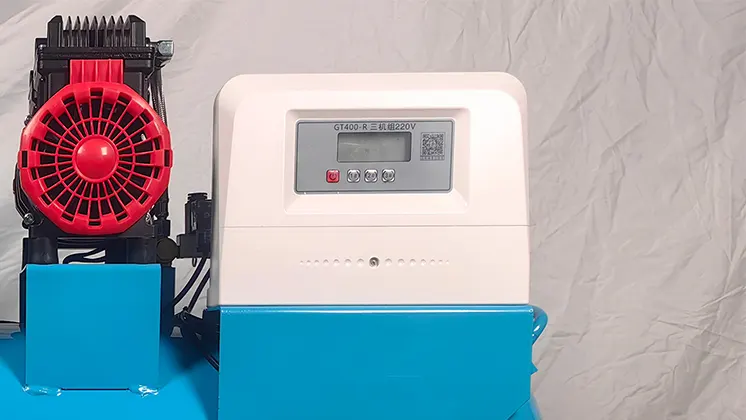

The Oil-Free Air Compressor – VP-14903-100 is a performance engineer designed to deliver superior air quality without oil contamination for the class of applications. Compressed air is stored in a 100-liter air receiver with a powerful 4.47 kW (6 hp) motor to provide steady airflow and low maintenance. The direct drive system allows easy control and operation while offering minimal torque during the initial operation through the industrial frequency, ultimately improving durability.

VP-14903-100

- Pressure(MPa): 0.8

- FAD(m³/min): 0.45

- Power(KW/HP): 4.47

- Air Receiver(L): 100

- Dimension(mm): 1070*350*750

- Weigt(kg): 68

- Pipe Diameter: G1/4

- Power Supply: 220V/50Hz

- Drive Mode: Direct Drive

- Startup Mode: Industrial Frequency Startup

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

VP-14901-30

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.15

-

Power(KW/HP): 1.49

-

Air Receiver(L): 30

-

Dimension(mm): 620*270*570

-

Weigt(kg): 22.5

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-14902-50

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.3

-

Power(KW/HP): 2.98

-

Air Receiver(L): 50

-

Dimension(mm): 680*330*670

-

Weigt(kg): 42

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-14904-120

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.6

-

Power(KW/HP): 5.96

-

Air Receiver(L): 120

-

Dimension(mm): 1300*400*760

-

Weigt(kg): 90

-

Pipe Diameter: G1/4, G1/2

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

VP-6001-30

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.08

-

Power(KW/HP): 0.6

-

Air Receiver(L): 30

-

Dimension(mm): 620*270*570

-

Weigt(kg): 21

-

Pipe Diameter: G1/4

-

Power Supply: 220V/50Hz

-

Drive Mode: Direct Drive

-

Startup Mode: Industrial Frequency Startup

VIEW MORE

You May Also Like

JX-20APMS-20HP/15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.3~1.7

-

Power(KW/HP): 15/20

VIEW MORE

JX-20APMX-15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.4~1.8

-

Power(KW/HP): 15/20

VIEW MORE

JX-20AS-15KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

VIEW MORE

B-X15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

VIEW MORE

Get In Touch