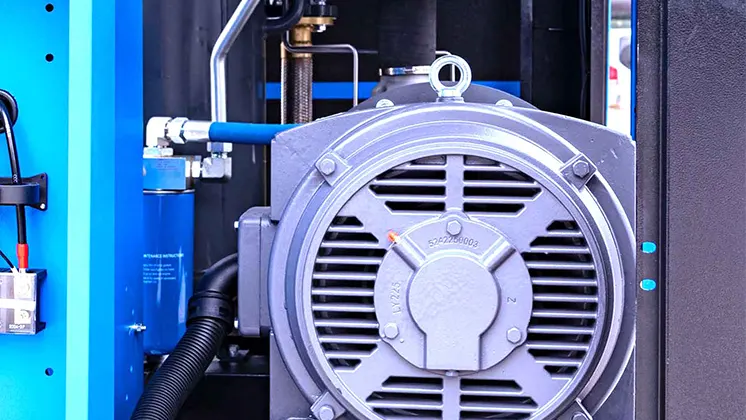

Air Compressor VFD (WEG Motor)

Perfect choice for air solution!

VFD air compressor (WEG Motor)

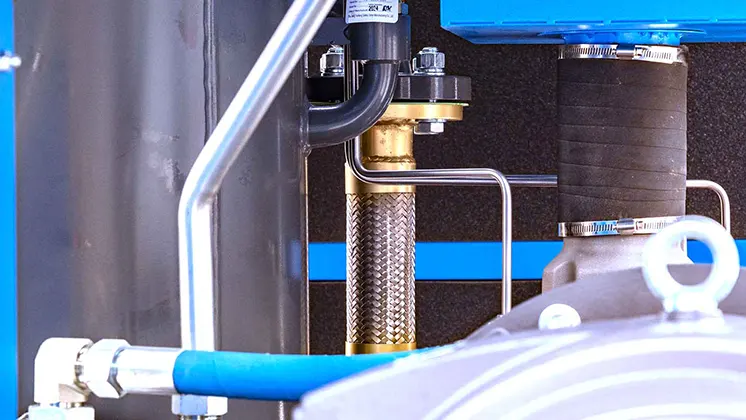

The JX 125AS-WEG air compressor with variable frequency drive and WEG electric motor is highly energy efficient and productive for industries. Designed with optimum levels of efficiency in air compressors this solution is appropriate for organizations that have varying demands but equally insist on stability. Primarily designed with 125 HP (90 kW) motor power and providing an excellent pressure performance range from low to high pressure.

JX-125AS-WEG

- Pressure(MPa): 0.8/1/1.3

- FAD (m³/min): 15.2/12.3/11.4

- Power(KW/HP): 90/125

- Weigt(kg): 1800

- Pipe Diameter: DN65

- Noise(dB): ≤82±2

- Dimension(mm): 2250*1510*1850

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-150AS-WEG

-

Pressure(MPa): 0.8/1/1.3

-

FAD (m³/min): 19.9/16.3/14.5

-

Power(KW/HP): 110/150

-

Weigt(kg): 1900

-

Pipe Diameter: DN65

-

Noise(dB): ≤82±2

-

Dimension(mm): 3250*2100*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-180AS-WEG

-

Pressure(MPa): 0.8/1/1.3

-

FAD (m³/min): 23/19.7/16

-

Power(KW/HP): 132/180

-

Weigt(kg): 3950

-

Pipe Diameter: DN100

-

Noise(dB): ≤82±2

-

Dimension(mm): 3250*2100*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-220AS-WEG

-

Pressure(MPa): 0.8/1/1.3

-

FAD (m³/min): 28.5/22.8/21.5

-

Power(KW/HP): 160/220

-

Weigt(kg): 4100

-

Pipe Diameter: DN100

-

Noise(dB): ≤84±2

-

Dimension(mm): 3250*2100*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-250AS-WEG

-

Pressure(MPa): 0.8/1/1.3

-

FAD (m³/min): 30/27/23

-

Power(KW/HP): 185/250

-

Weigt(kg): 4800

-

Pipe Diameter: DN125

-

Noise(dB): ≤84±2

-

Dimension(mm): 3550*2300*2300

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-15AS-11KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

B-X15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

VIEW MORE

B-XG20AL

-

Pressure(MPa): 0.8-1.0

-

Exhaust Volume(m³/min): 2.3-2.1

-

Power(KW/HP): 15/20

VIEW MORE

Get In Touch