Air Compressor Vfd Energy Savings (WEG Motor)

Perfect choice for air solution!

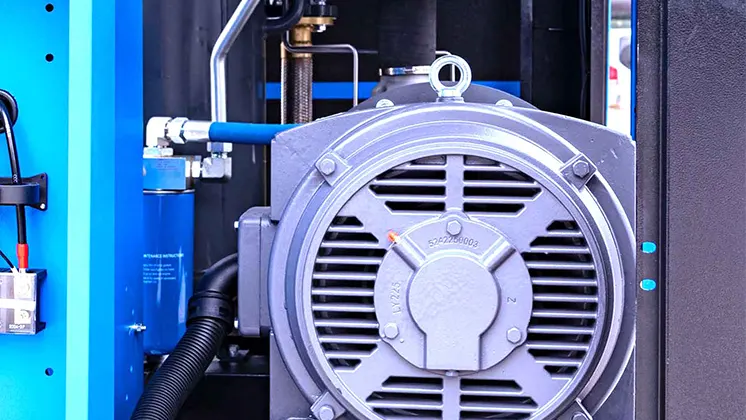

VFD air compressor (WEG Motor)

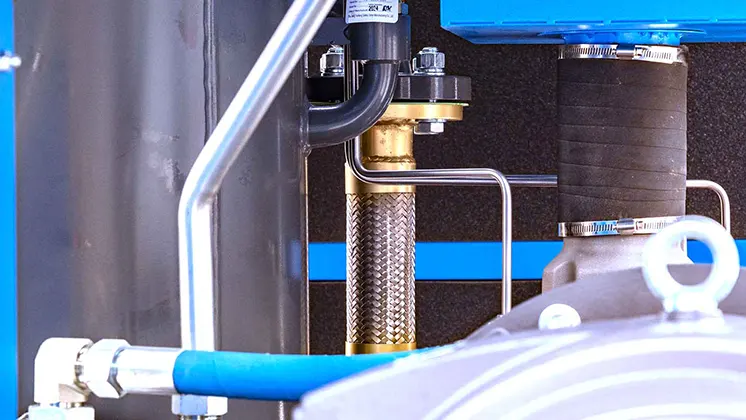

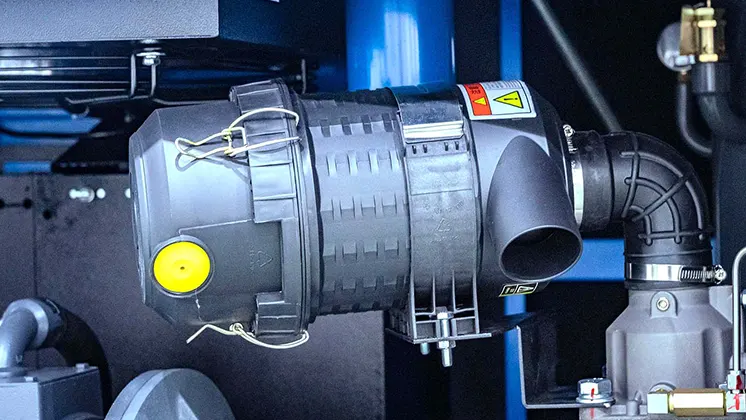

Air Compressor VFD Energy Savings – JX-270AS-WEG: the Business of delivering energy optimally in multiple segments to encompass producing some of the most effective air compressors with higher time efficiency than its rivals. By use of VFD technology in its motor speed control, this compressor ensures that it alters the pushing/pulling rate with the efficiency of the motor, thus being suitable for energy reduction and low operating cost. Designed for use in structures where there is a continuous and intricate need for compressed air, the JX-270AS-WEG delivers the promise of performance and durability.

JX-270AS-WEG

- Pressure(MPa): 0.8/1/1.3

- FAD (m³/min): 32.5/29.2/25.5

- Power(KW/HP): 200/270

- Weigt(kg): 5000

- Pipe Diameter: DN125

- Noise(dB): ≤86±2

- Dimension(mm): 3550*2300*2300

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-150AS-WEG

-

Pressure(MPa): 0.8/1/1.3

-

FAD (m³/min): 19.9/16.3/14.5

-

Power(KW/HP): 110/150

-

Weigt(kg): 1900

-

Pipe Diameter: DN65

-

Noise(dB): ≤82±2

-

Dimension(mm): 3250*2100*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-180AS-WEG

-

Pressure(MPa): 0.8/1/1.3

-

FAD (m³/min): 23/19.7/16

-

Power(KW/HP): 132/180

-

Weigt(kg): 3950

-

Pipe Diameter: DN100

-

Noise(dB): ≤82±2

-

Dimension(mm): 3250*2100*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-250AS-WEG

-

Pressure(MPa): 0.8/1/1.3

-

FAD (m³/min): 30/27/23

-

Power(KW/HP): 185/250

-

Weigt(kg): 4800

-

Pipe Diameter: DN125

-

Noise(dB): ≤84±2

-

Dimension(mm): 3550*2300*2300

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-300AS-WEG

-

Pressure(MPa): 0.8/1/1.3

-

FAD (m³/min): 38/33/28.8

-

Power(KW/HP): 220/300

-

Weigt(kg): 5900

-

Pipe Diameter: DN125

-

Noise(dB): ≤86±2

-

Dimension(mm): 3760*2260*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-15AS-11KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

JX-10APML

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

JX-10APMLT

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

Get In Touch