VFD Drive Air Compressor (WEG Motor)

Perfect choice for air solution!

VFD air compressor (WEG Motor)

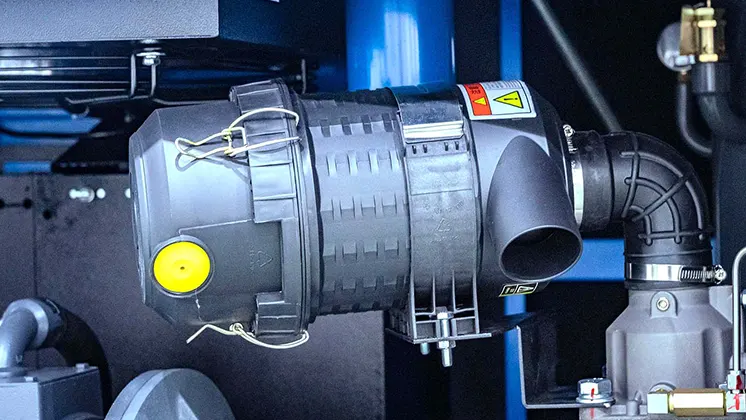

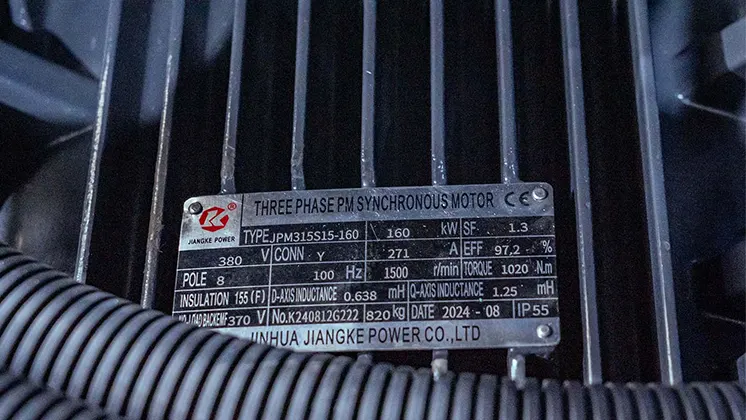

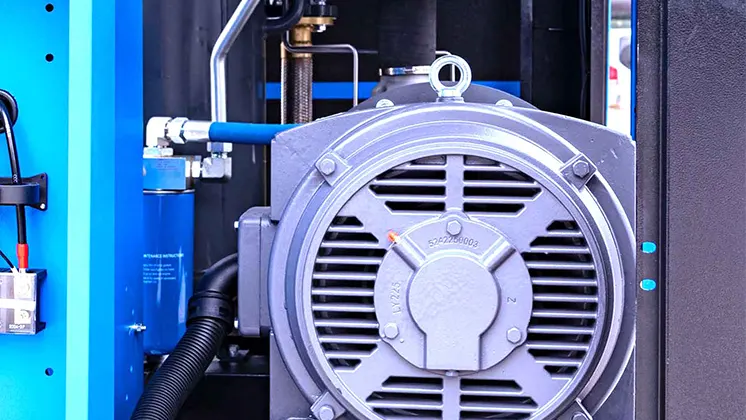

JX 180AS WEG VFD Drive Air Compressor is the most innovative air compressor equipped with a Variable Frequency Drive and an efficient WEG motor. This is a high-level air compressor perfect for industries with fluctuating air demand and where energy consumption has to be minimized based on different pressures.

JX-180AS-WEG

- Pressure(MPa): 0.8/1/1.3

- FAD (m³/min): 23/19.7/16

- Power(KW/HP): 132/180

- Weigt(kg): 3950

- Pipe Diameter: DN100

- Noise(dB): ≤82±2

- Dimension(mm): 3250*2100*2200

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-100AS-WEG

-

Pressure(MPa): 0.8/1/1.3

-

FAD (m³/min): 12.3/10.8/9.1

-

Power(KW/HP): 75/100

-

Weigt(kg): 1500

-

Pipe Diameter: G2 1/2

-

Noise(dB): ≤80±2

-

Dimension(mm): 2100*1400*1650

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-150AS-WEG

-

Pressure(MPa): 0.8/1/1.3

-

FAD (m³/min): 19.9/16.3/14.5

-

Power(KW/HP): 110/150

-

Weigt(kg): 1900

-

Pipe Diameter: DN65

-

Noise(dB): ≤82±2

-

Dimension(mm): 3250*2100*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-220AS-WEG

-

Pressure(MPa): 0.8/1/1.3

-

FAD (m³/min): 28.5/22.8/21.5

-

Power(KW/HP): 160/220

-

Weigt(kg): 4100

-

Pipe Diameter: DN100

-

Noise(dB): ≤84±2

-

Dimension(mm): 3250*2100*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-250AS-WEG

-

Pressure(MPa): 0.8/1/1.3

-

FAD (m³/min): 30/27/23

-

Power(KW/HP): 185/250

-

Weigt(kg): 4800

-

Pipe Diameter: DN125

-

Noise(dB): ≤84±2

-

Dimension(mm): 3550*2300*2300

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-15AS-11KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

JX-10APML

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

JX-10APMLT

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

Get In Touch