12v High Volume Low Pressure Air Compressor

Perfect choice for air solution!

Two Stage Air Compressors (Low Preassure)

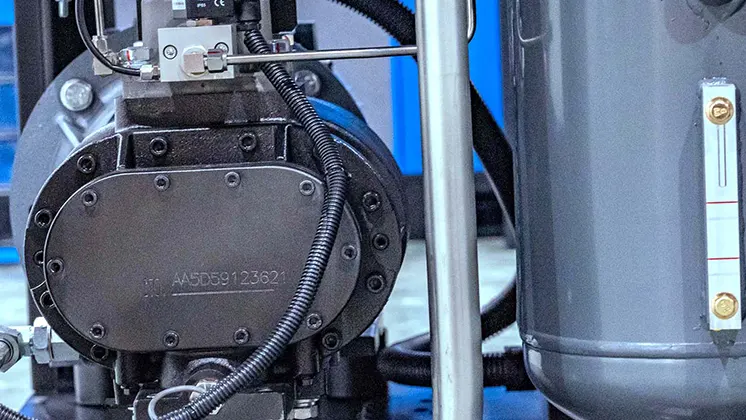

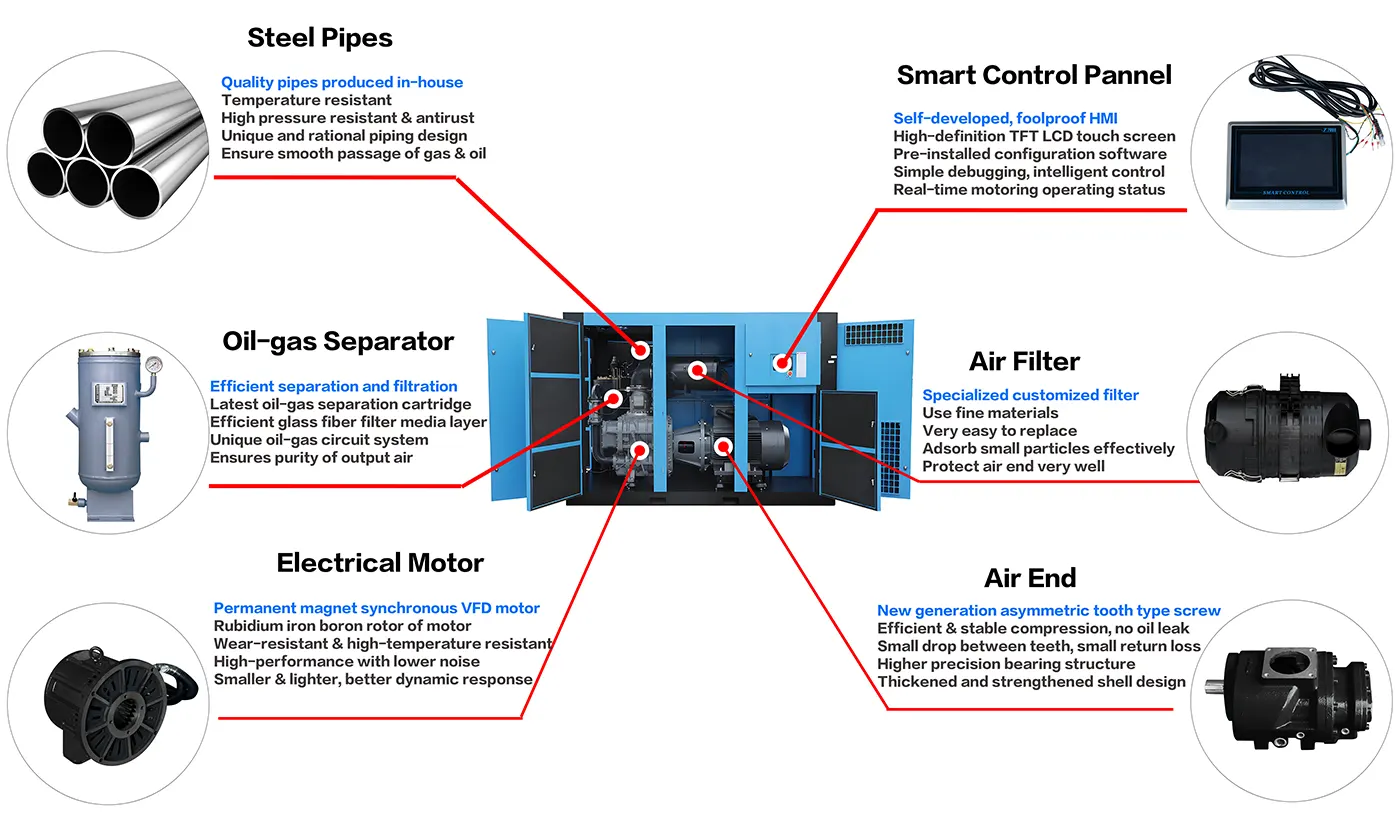

The 12V High Volume Low Pressure Air Compressor – JXL-250APM2 is a commercial class air compressor that is designed in form and function to provide high volume air with low pressure that is perfect for many applications where high pressure is not necessary but high volume of air is needed. This model is developed to withstand tough operation in industries and comes with 250 HP (185 kW) motor.

JXL-250APM2

- Pressure(MPa): 0.4/0.5

- FAD (m³/min): 52/45

- Power(KW/HP): 185/250

- Weigt(kg): 5800

- Pipe Diameter: DN125

- Dimension(mm): 3550*2300*2300

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JXL-180APM2

-

Pressure(MPa): 0.4/0.5

-

FAD (m³/min): 38/35

-

Power(KW/HP): 132/180

-

Weigt(kg): 4000

-

Pipe Diameter: DN100

-

Dimension(mm): 3250*2100*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JXL-220APM2

-

Pressure(MPa): 0.4/0.5

-

FAD (m³/min): 47/42

-

Power(KW/HP): 160/220

-

Weigt(kg): 5500/4400

-

Pipe Diameter: DN125/DN100

-

Dimension(mm): 3550*2300*2300/3250*2100*2200

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JXL-270APM2

-

Pressure(MPa): 0.4/0.5

-

FAD (m³/min): 57/51.5

-

Power(KW/HP): 200/270

-

Weigt(kg): 6000

-

Pipe Diameter: DN125

-

Dimension(mm): 3550*2300*2300

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JXL-300APM2

-

Pressure(MPa): 0.4/0.5

-

FAD (m³/min): 62/55

-

Power(KW/HP): 220/300

-

Weigt(kg): 8000

-

Pipe Diameter: DN125

-

Dimension(mm): 4300*2300*2430

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-15AS-11KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

JX-10APML

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

JX-10APMLT

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

Get In Touch