High Flow Low Pressure Air Compressor

Perfect choice for air solution!

Low Pressure Air Compressor

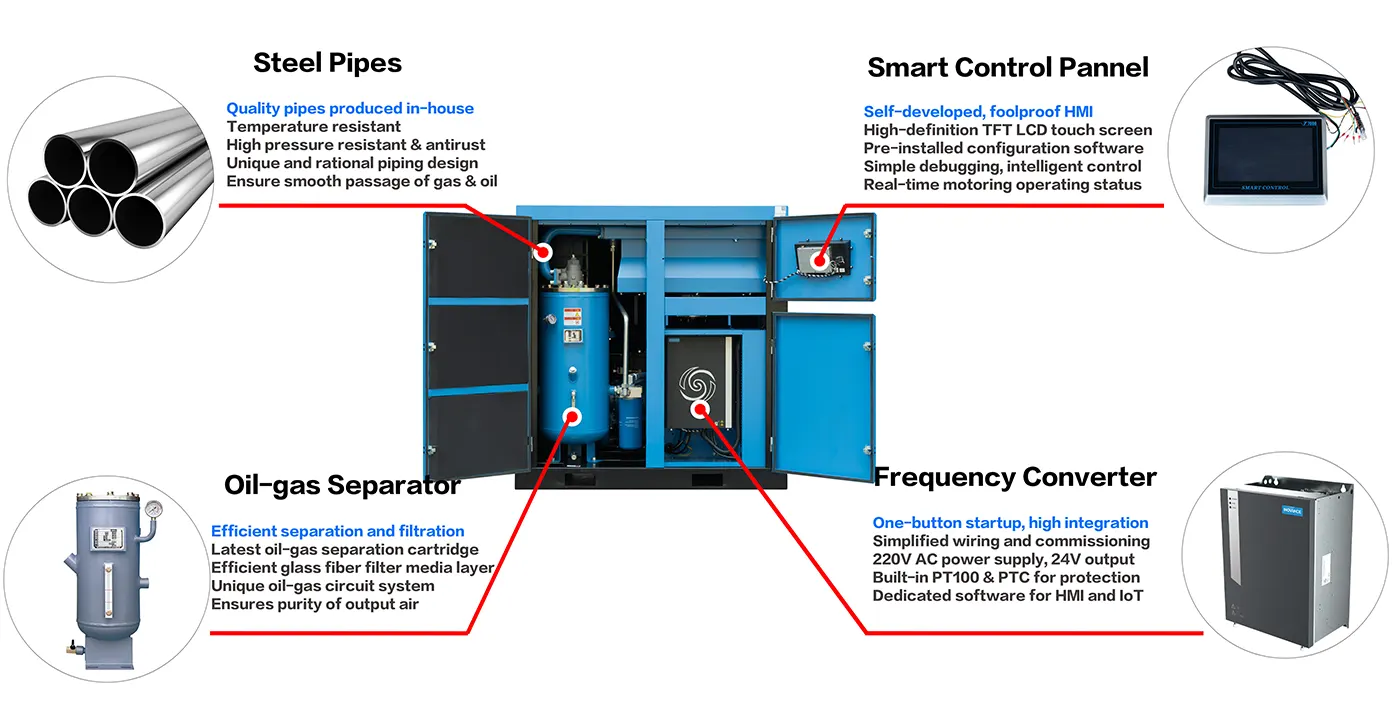

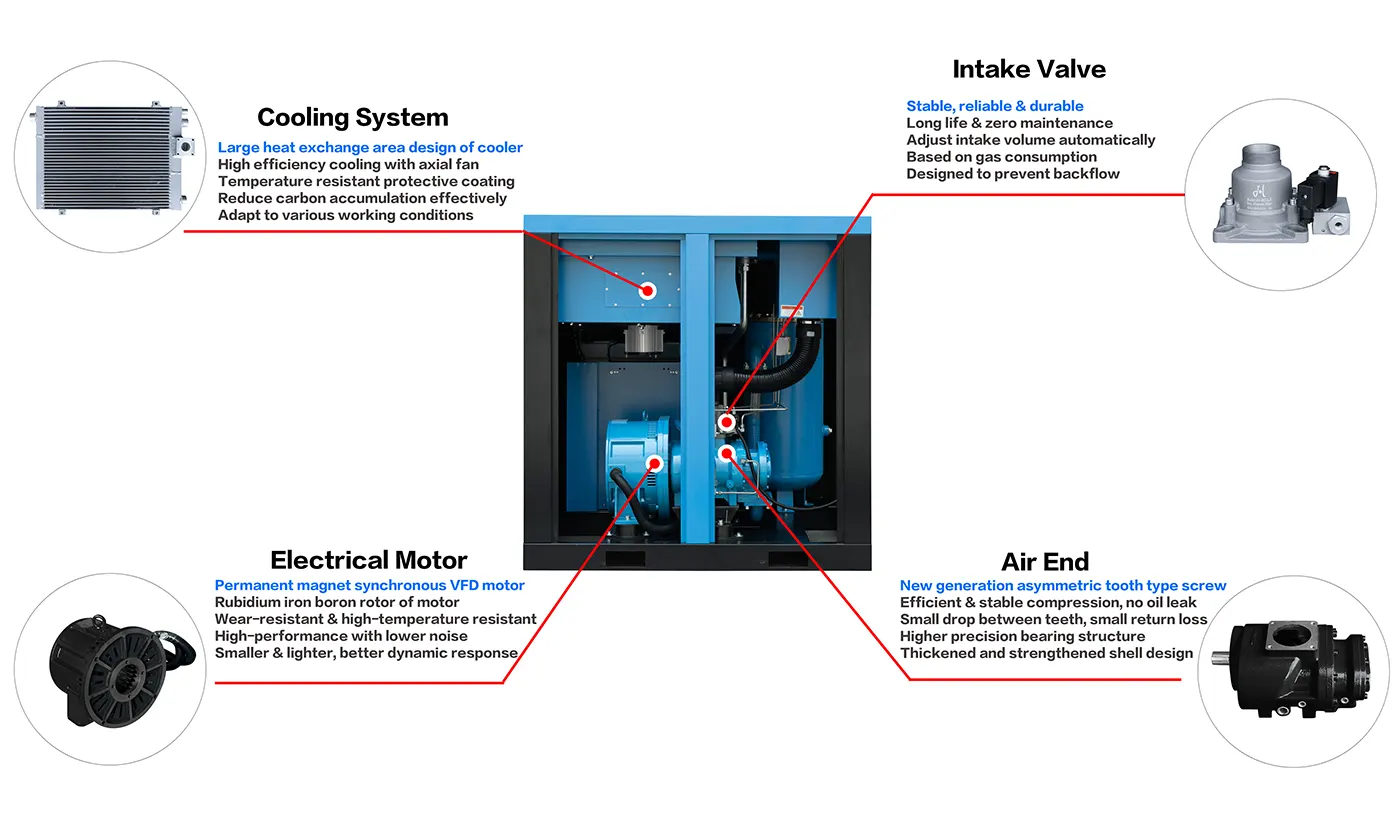

The JXL-150APM High Flow Low Pressure Air Compressor is intended for volume use in low pressure industry sectors. It provides quali)-ty air with variable pressure options that make it suitable in industries that demand large amounts of low pressure compressed air. It is driven by a 150 HP (110 kW) motor with variable pressure and air delivery options upto 0.2-0.5 MPa (29-73 psi) and FAD up to 43m³/min(1518.3CFM).

JXL-150APM

- Pressure(MPa): 0.2/0.3/0.4/0.5

- FAD (m³/min): 43/34/29.6/24/

- Power(KW/HP): 110/150

- Weigt(kg): 5300/4000/3500/3200

- Pipe Diameter: DN200/DN125/DN100/DN80

- Dimension(mm): 3600*2200*2200/3000*1900*1950

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JXL-75APM

-

Pressure(MPa): 0.2/0.3/0.4/0.5

-

FAD (m³/min): 20.5/17/14.2/13.3

-

Power(KW/HP): 55/75

-

Weigt(kg): 2900/1600/1550

-

Pipe Diameter: DN125/DN100/DN80/G2

-

Dimension(mm): 2500*1650*1900/2100*1300*1650

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JXL-125APM

-

Pressure(MPa): 0.2/0.3/0.4/0.5

-

FAD (m³/min): 34/28/24/20

-

Power(KW/HP): 90/125

-

Weigt(kg): 3100/3100/3000/2950

-

Pipe Diameter: DN125/DN100/DN80

-

Dimension(mm): 3000*1900*1950/2500*1650*1900

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JXL-180APM

-

Pressure(MPa): 0.2/0.3/0.4/0.5

-

FAD (m³/min): 52/42/33/30.5

-

Power(KW/HP): 132/180

-

Weigt(kg): 5800/4300/4100/3700

-

Pipe Diameter: DN200/DN125/DN100/DN80

-

Dimension(mm): 3600*2200*2200/3000*1900*1950

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JXL-220APM

-

Pressure(MPa): 0.2/0.3/0.4/0.5

-

FAD (m³/min): 60/50/44/34

-

Power(KW/HP): 160/220

-

Weigt(kg): 6500/6200/4300/4000

-

Pipe Diameter: DN200/DN100/DN100

-

Dimension(mm): 3600*2200*2200/3000*1900*1950

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-15AS-11KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

JX-10APML

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

JX-10APMLT

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

Get In Touch