Two Stage Screw Air Compressor Machines

Please allow me to present the JX-125APML2 Two-Stage Screw Air Compressor: an enduring and effective tool produced for extensive commercial application. The compressor of this range is fitted with a motor of 125HP (90 kW) to ensure that the air is compressed to high pressures for uses where high pressure is required. This is made possible by its two-level technology for the performance and efficiency of the blades under enhanced circumstances.

- Pressure(MPa): 1.6

- FAD (m³/min): 11.2

- Power(KW/HP): 90/125

- Dimension(mm): 2600*1900*1890

- Weigt(kg): 2600

- Pipe Diameter: DN80

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

The JX-125APML2 operates at a pressure of 1.6 MPa (232 psi) and the Free Air Delivery (FAD) is 11.2 m³/min (395.5 CFM). As for the dimensions of the machine, it is made to have 2600mm of width 1900mm of length an overall height of 1890mm, and an overall weight is 2600kg making the machine appropriate for industrial use. It is fitted with a DN80 pipe diameter which is good for delivering a lot of air, and as such, it is ideal for commercial use.

- Two-Stage Compression: This makes the air compressor work to optimum efficiency with low power consumption to produce high output since it contains two stages of compressed air.

- High-Pressure Output: It works at 1.6 MPa (232psi) which makes it suitable for industries that require high-pressure air.

- High Air Delivery: This delivers up to 11.2 m³/min of air, the model is highly useful to large factories and industrial buildings that require a large amount of air.

- Durable Construction: These are designed for use where they have to withstand frequent and intensive use and thus the structure of the unit is rather sturdy while the parts are.

- Compact for Its Power: Due to the unit’s capacity and the size of the unit described here, the unit can provide a high level of functionality for a large operation.

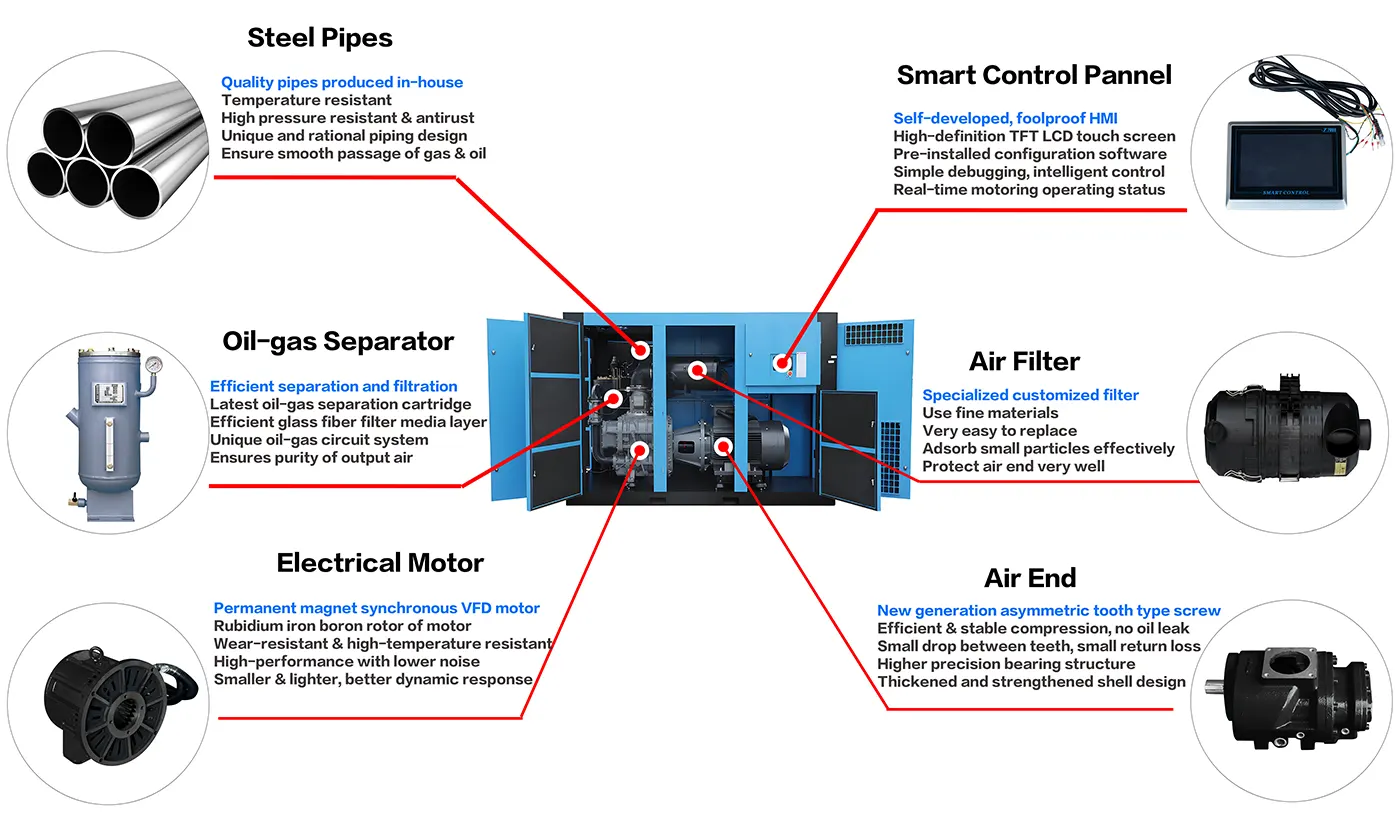

- Compressor Unit: In the middle of it all refrigerating the air through its two-stage compression formula, efficiently.

- Air Filters: There is a need to prevent both debris and dust entry into the compressor through the air filter while protecting the inside of the compressor.

- Lubrication System: It helps in operation efficiency and reduces the momentary drag or friction, by supply of necessary lubricants for the compressor.

- Pressure Regulators: Regulates pressure of the vessels and sustains the operations under their intended pressure of the system.

- Pipes and Fittings: Especially, it is necessary to carry out routine inspections of pipelines, as well as used fittings, to prevent leaks and achieve the highest performance.

- Routine Maintenance: Filters, lubricating levels as well as other wearing parts should also be checked from time to time to maximize the performance of the machinery.

- Ensure Proper Ventilation: Store the unit in a well-aerated environment to reduce heat production when in operation.

- Check Power Supply: Make sure that the electrical voltage and frequency supplied to the compressor are not beyond their recommended ratings to avoid such cases.

- Monitor Pressure Levels: They need to monitor and manage the operating pressures so as not to overwhelm this important infrastructure.

- Manufacturing Industries: They are widely applied in industries, particularly in manufacturing industries where high-pressure air is required by the tools and equipment.

- Oil and Gas Sector: Most suitable for delivering high-pressure air in enforcing circumstances for example during drilling.

- Automotive and Aerospace Industries: Well suited for charging Air tools for use in line production and maintenance operations.

- Construction and Engineering Sites: Applicable for providing a constant and high pressure of air to numerous pneumatic tools and appliances.

- HVAC Systems: It can be fitted on heating ventilation and air conditioning systems where there is pressure for high air pressure requirements.

| Item | Technical Parameter | |

| Unit Model | JX-125APML2 | |

| Pressure(MPa) | 1.6 | |

| Pressure(psi) | 232 | |

| FAD(m³/min) | 11.2 | |

| FAD(CFM) | 395.5 | |

| Power(kW/hp) | 90/125 | |

| Dimension(mm) | 2600*1900*1890 | |

| Weight(Kg) | 2600 | |

| Pipe Diameter | DN80 | |

-

Pressure(MPa): 1.6

-

FAD (m³/min): 9.0

-

Power(KW/HP): 75/100

-

Dimension(mm): 2100*1440*1650

-

Weigt(kg): 1300

-

Pipe Diameter: G1/2

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 1.6

-

FAD (m³/min): 15.0

-

Power(KW/HP): 110/150

-

Dimension(mm): 2600*1900*1890

-

Weigt(kg): 2700

-

Pipe Diameter: DN80

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 1.6

-

FAD (m³/min): 18.5

-

Power(KW/HP): 132/180

-

Dimension(mm): 3250*2100*2200

-

Weigt(kg): 3900

-

Pipe Diameter: DN100

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 1.6

-

FAD (m³/min): 21.0

-

Power(KW/HP): 160/220

-

Dimension(mm): 3250*2100*2200

-

Weigt(kg): 4000

-

Pipe Diameter: DN100

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE